Method for cultivating barren sandy backfill to supplement cultivated land soil development levels

A technology for arable soil and backfilling, which is applied in the fields of land preparation methods, calcareous fertilizers, applications, etc., and can solve the problems of poor quality grade, poor structure, and low nutrient content of arable land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

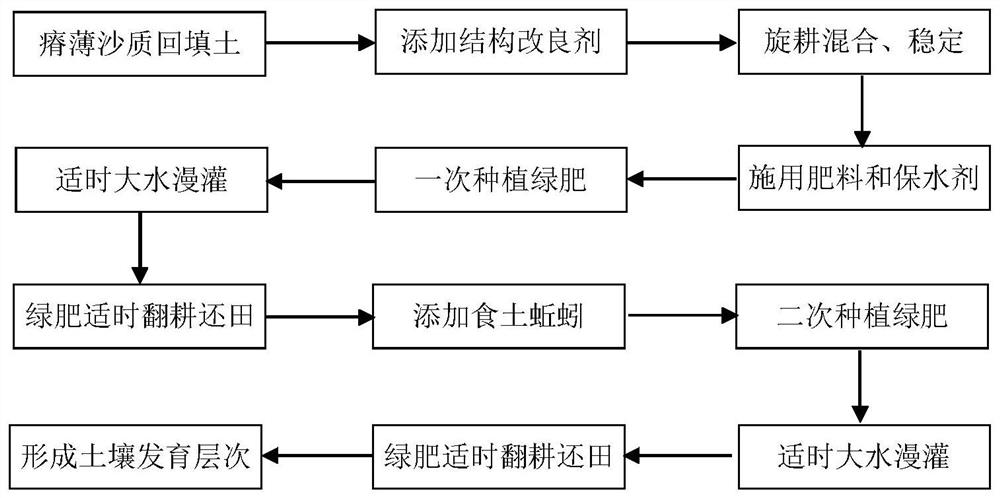

Method used

Image

Examples

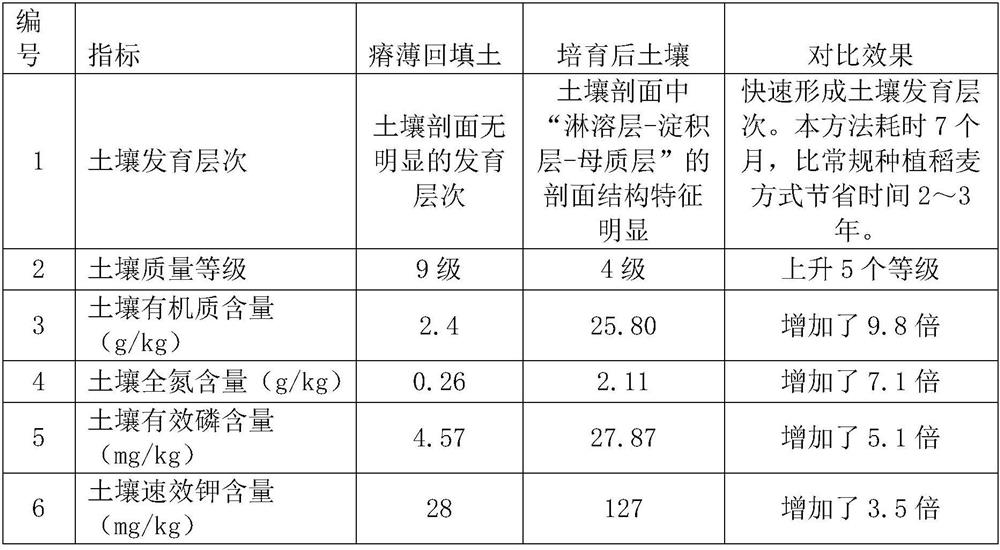

Embodiment 1

[0020] A method for cultivating barren sandy backfill soil to supplement the soil development level of arable land, specifically comprising the following steps:

[0021] (1) The aggregate structure of backfill soil in the plow layer is formed rapidly

[0022] After the barren sandy backfill is leveled, 400 kg / mu of improver and 40 kg / mu of nitrogen, phosphorus and potassium compound fertilizer are spread on the soil surface. The improver is composed of calcium oxide, peat and biochar. The mass percentage of each component is: 40% of calcium oxide, 30% of peat and 30% of biochar. Immediately after spreading, use a rotary tiller to till once, with a depth of 10 cm.

[0023] (2) Start the production capacity of backfill

[0024] After rotary tillage, the soil was left to stand for 1 month to promote the formation and stability of the soil aggregate structure. Apply fertilizer and water retaining agent to the soil surface at the same time. The fertilizer is composed of vermico...

Embodiment 2

[0033] (1) The aggregate structure of backfill soil in the plow layer is formed rapidly

[0034] After the barren sandy backfill soil is leveled, 300 kg / mu of improver and 30 kg / mu of nitrogen, phosphorus and potassium compound fertilizer are spread on the soil surface. The improver is composed of calcium oxide, peat and biochar. The calcium oxide content is 60%, the peat content is 20%, and the biochar content is 20%. Immediately after spreading, use a rotary tiller to till once, with a depth of 15 cm.

[0035] (2) Start the production capacity of backfill

[0036] After rotary tillage, the soil was left to stand for 1 month to promote the formation and stability of the soil aggregate structure. Apply fertilizer and water retaining agent to the soil surface at the same time. The fertilizer consists of vermicompost organic fertilizer and nitrogen, phosphorus and potassium compound fertilizer. The amount of vermicompost organic fertilizer is 2 tons / mu, and the amount of nitr...

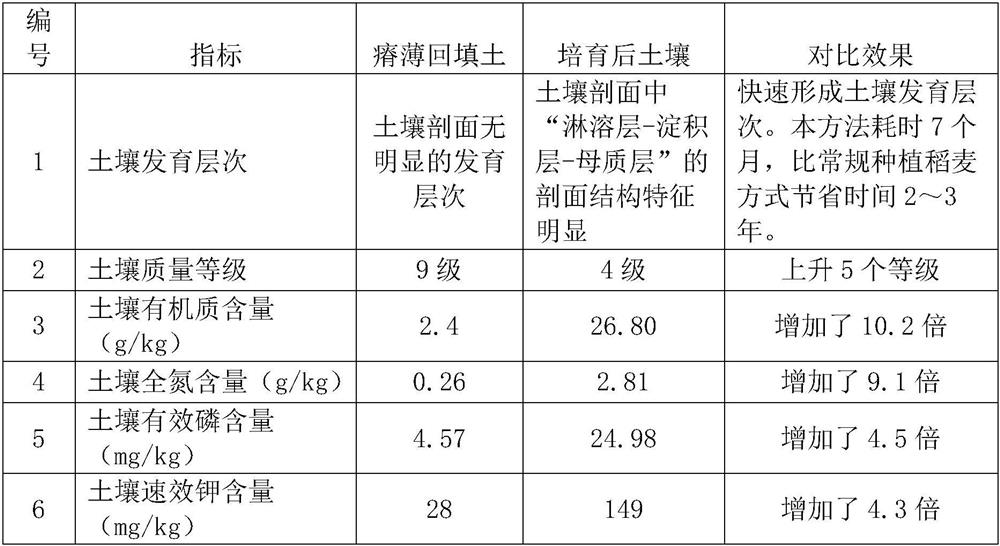

Embodiment 3

[0045] (1) The aggregate structure of backfill soil in the plow layer is formed rapidly

[0046]After the barren sandy backfill is leveled, 500 kg / mu of improver and 50 kg / mu of nitrogen, phosphorus and potassium compound fertilizer are spread on the soil surface. The improver is composed of calcium oxide, peat and biochar. The calcium oxide content is 50%, the peat content is 25%, and the biochar content is 25%. Immediately after spreading, use a rotary tiller to till once, with a depth of 12 cm.

[0047] (2) Start the production capacity of backfill

[0048] After rotary tillage, the soil was left to stand for 1 month to promote the formation and stability of the soil aggregate structure. Apply fertilizer and water retaining agent to the soil surface at the same time. The fertilizer consists of vermicompost organic fertilizer and nitrogen, phosphorus and potassium compound fertilizer. The amount of vermicompost organic fertilizer is 1.5 tons / mu, and the amount of nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com