Preparation method of charcoal ammonia adsorbent

A technology of ammonia adsorption and biochar, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of poor adsorption effect and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

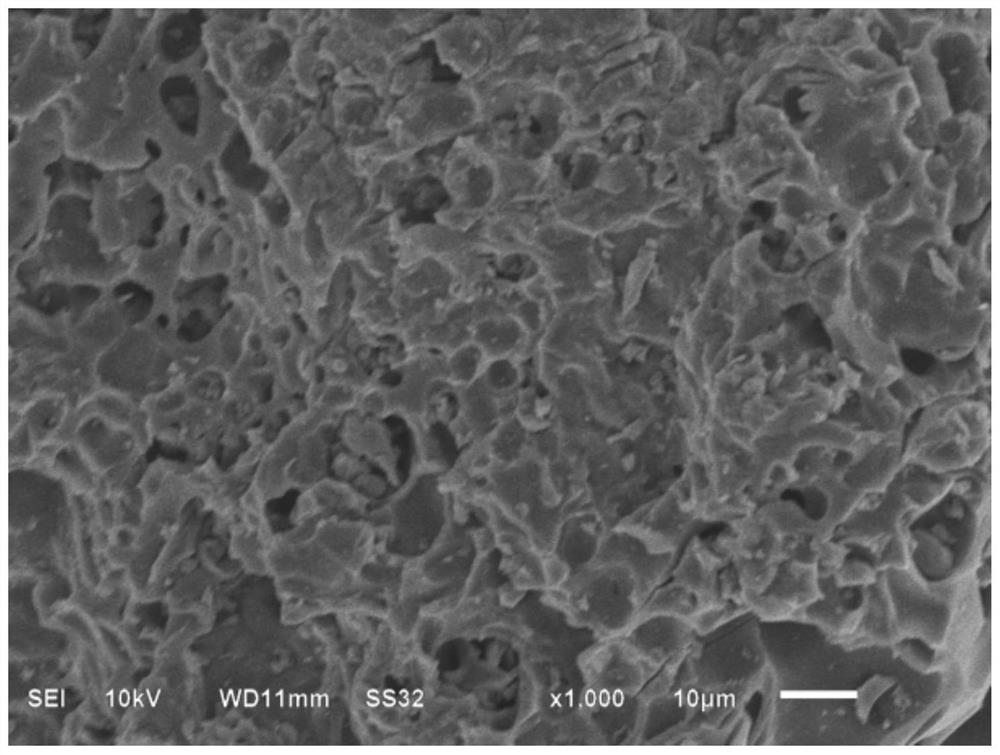

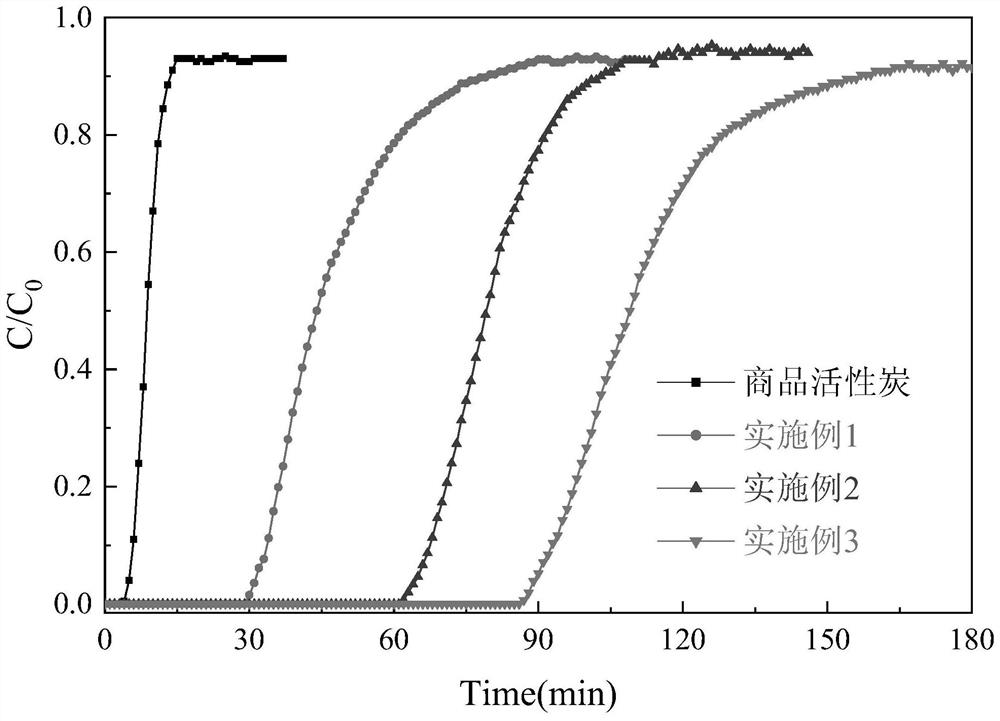

Embodiment 1

[0027] Peel the pomelo peel and wash it, dry it at 120°C and crush it, and then use a 40-mesh standard sieve to get the hole powder. Put the powder into a beaker, add absolute ethanol at a ratio of 1g:20mL and soak for 12 hours, filter and dry, seal and set aside. Put 3g of pomelo peel powder into a 25ml beaker, use the equal volume impregnation method, add zinc chloride solution with an impregnation ratio of 1:1, mix well, and place at room temperature for 10h. Dry the mixture and transfer it to a tube furnace, control the heating rate to 10°C / min, heat to 450°C, and keep for 50min. Take it out after cooling down, soak it in (1+10) hydrochloric acid for 20min, pour it into a suction filtration device and wash it with hot water until the filtrate pH=6~7, then transfer the washed solid phase product to an oven, and drum it at 120°C Air-dry for more than 3 hours until the surface moisture is completely removed, and then pass through a 40-mesh sieve after grinding to obtain a ca...

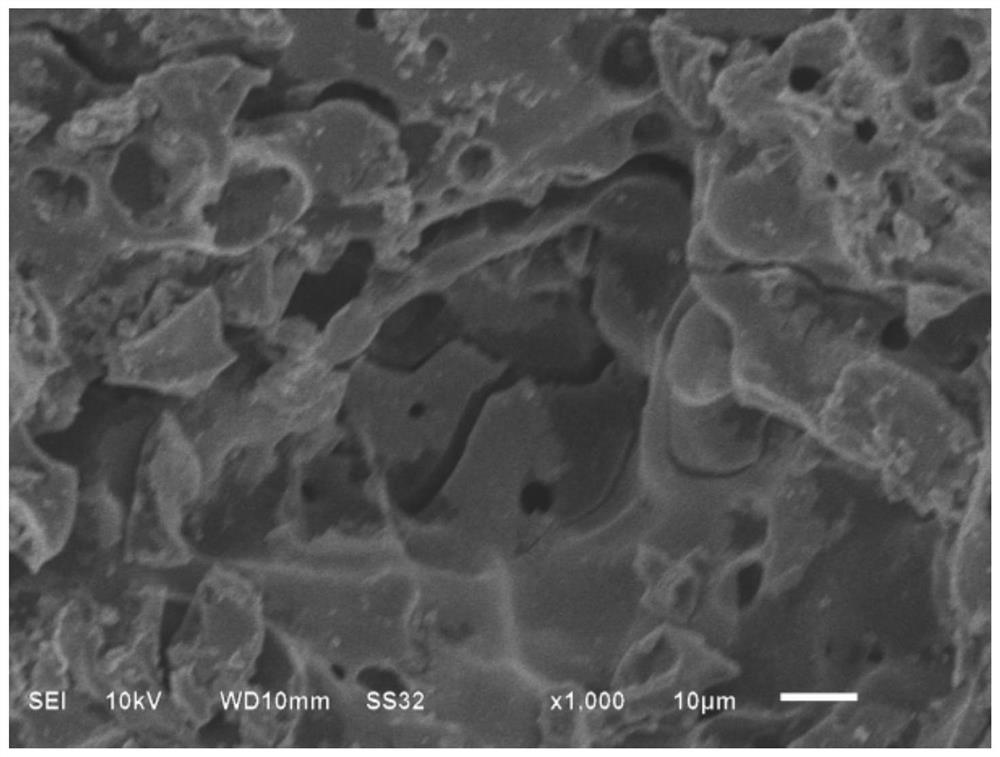

Embodiment 2

[0030] Wash, dry and grind the pomelo peel, and then use a 40-mesh standard sieve to get the perforated powder. Put the powder into a beaker, add absolute ethanol at a ratio of 1g:15mL and soak for 24 hours, filter and dry, seal and set aside. Put 4g pomelo peel powder into a 25ml beaker, use the equal volume impregnation method, add zinc chloride solution with an impregnation ratio of 1:0.8, mix well, and place at room temperature for 11h. The mixture was dried and transferred to a tube furnace, the heating rate was controlled at 5°C / min, heated to 400°C, and kept for 60min. Take it out after cooling down, soak in (1+8) hydrochloric acid for 35min, pour it into a suction filtration device and wash it with hot water until the filtrate pH=6~7, then transfer the washed solid phase product to an oven, and drum at 120°C Air-dry for more than 3 hours until the surface moisture is completely removed, and then pass through a 40-mesh sieve after grinding to obtain a carbon material. ...

Embodiment 3

[0033] After the pomelo peel was washed, dried and ground to 40 meshes, the porous powder was put into a beaker, and absolute ethanol was added at a ratio of 1g:25mL and soaked for 15 hours, filtered and dried, and sealed for later use. Put 6g of pomelo peel powder into a 25ml beaker, use the equal volume impregnation method, add zinc chloride solution with an impregnation ratio of 1:1.25, mix well, and place at room temperature for 12h. The mixture was dried and transferred to a tube furnace, the heating rate was controlled at 30°C / min, heated to 415°C and kept for 60min. Remove after cooling down, soak in (1+9) hydrochloric acid for 30min, pour into a suction filtration device and wash with hot water until the filtrate pH=6~7, then transfer the washed solid phase product to an oven, and drum at 110°C Air-dry for more than 3 hours until the surface moisture is completely removed, and then pass through a 40-mesh sieve after grinding to obtain a carbon material.

[0034] Immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com