A method for high-efficiency and low-cost thermal reduction nickel plating on the surface of silicon carbide particles

A silicon carbide particle, low-cost technology, applied in the field of silicon carbide surface modification, can solve the problems affecting the application of nickel coating on the surface of silicon carbide powder, complicated processing process, difficult to handle the plating solution, etc. The effect of reducing risk and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

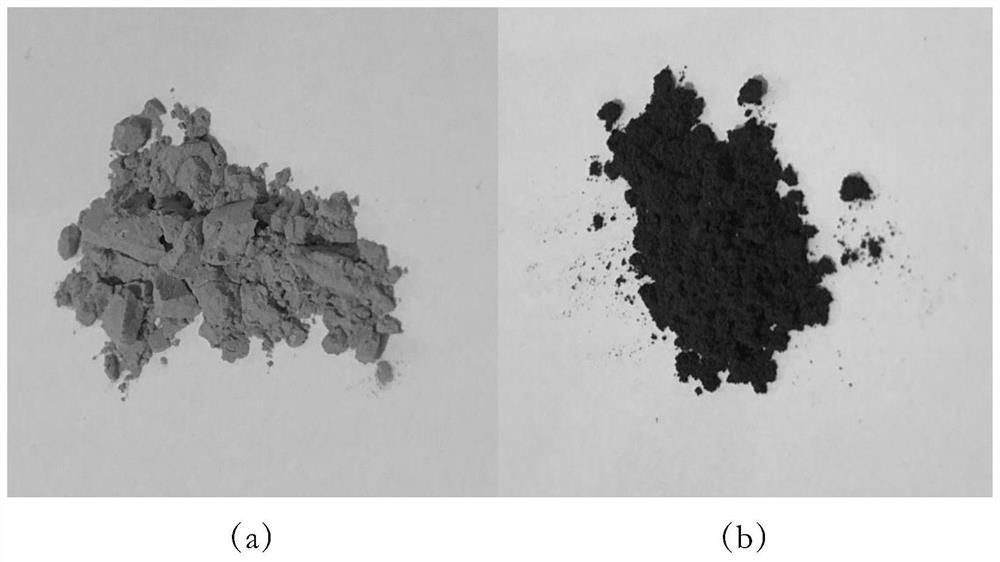

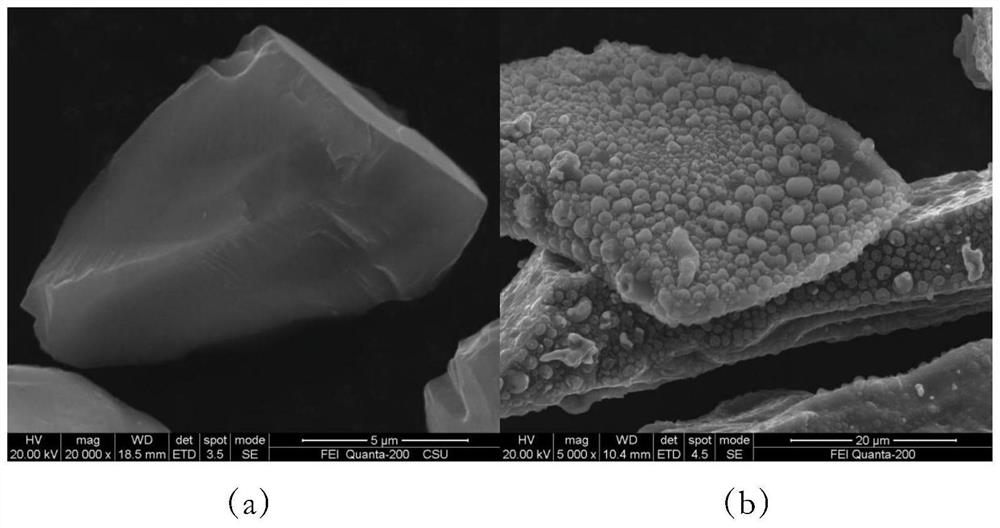

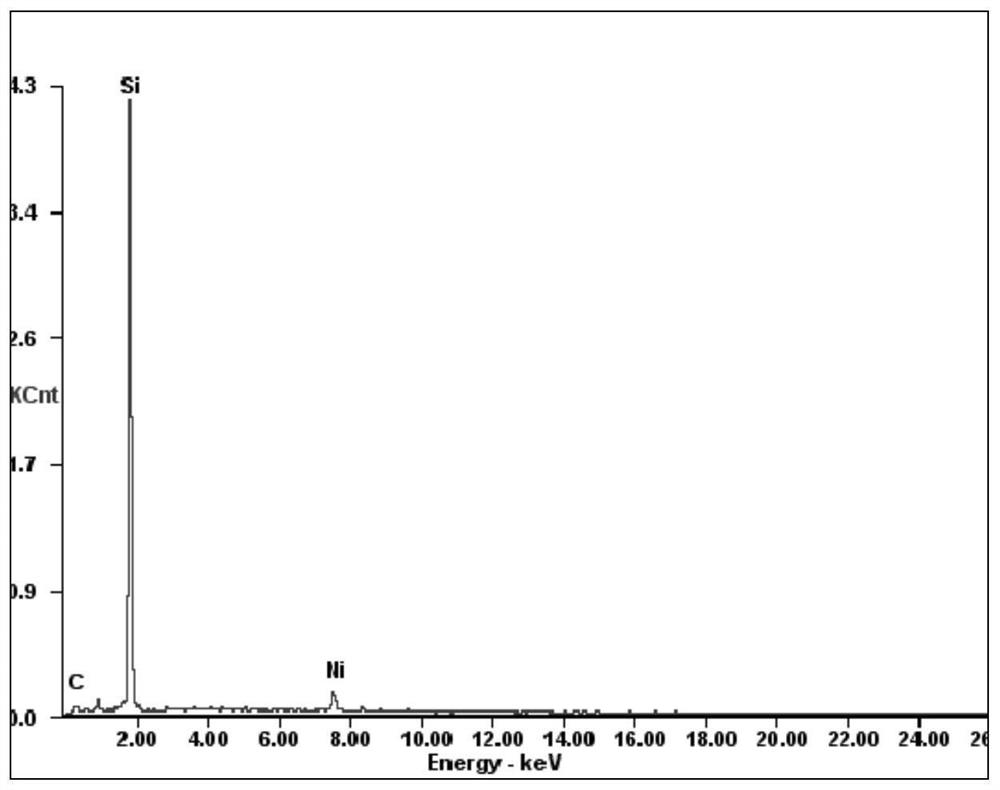

[0039] (1) Dissolve 200g of basic nickel carbonate at room temperature in 250mL of ammonia water, add 500g of polyacrylamide solution with a mass fraction of 5% under the action of stirring and stir to dissolve completely, and under the action of strong stirring Slowly add 1Kg of silicon carbide particles, so that the silicon carbide powder particles are fully infiltrated and dispersed in the solution, ensuring that the surface of the silicon carbide particles is covered by the dissolved basic nickel carbonate. After sealing and storing the fully soaked silicon carbide powder particles, let it stand for 6 hours to further fully dissolve the basic nickel carbonate in the ammonia solution to ensure the integrity of the coating. Take fully wrapped silicon carbide particles, dry them at 80°C for 2 hours, and obtain pretreated silicon carbide powder particles after preliminary crushing.

[0040] (2) Take the pretreated silicon carbide powder sample obtained above and place it in a ...

Embodiment 2

[0045] (1) Dissolve 100g of basic nickel carbonate at room temperature in 250mL of ammonia water, add 500g of polyacrylamide solution with a mass fraction of 5% under the action of stirring and stir to dissolve completely, and under the action of strong stirring Slowly add 1Kg of silicon carbide particles, so that the silicon carbide powder particles are fully infiltrated and dispersed in the solution, ensuring that the surface of the silicon carbide particles is covered by the dissolved basic nickel carbonate. After sealing and storing the fully soaked silicon carbide powder particles, let it stand for 6 hours to further fully dissolve the basic nickel carbonate in the ammonia solution to ensure the integrity of the coating. Take fully wrapped silicon carbide particles, dry them at 80°C for 2 hours, and obtain pretreated silicon carbide powder particles after preliminary crushing.

[0046] (2) Take the pretreated silicon carbide powder sample obtained above and place it in a ...

Embodiment 3

[0048] (1) Dissolve 300g of basic nickel carbonate at room temperature in 250mL of ammonia water, add 500g of polyacrylamide solution with a mass fraction of 5% under the action of stirring and stir to dissolve completely, and under the action of strong stirring Slowly add 1Kg of silicon carbide particles, so that the silicon carbide powder particles are fully infiltrated and dispersed in the solution, ensuring that the surface of the silicon carbide particles is covered by the dissolved basic nickel carbonate. After sealing and storing the fully soaked silicon carbide powder particles, let it stand for 6 hours to further fully dissolve the basic nickel carbonate in the ammonia solution to ensure the integrity of the coating. Take fully wrapped silicon carbide particles, dry them at 80°C for 2 hours, and obtain pretreated silicon carbide powder particles after preliminary crushing.

[0049] (2) Take the pretreated silicon carbide powder sample obtained above and place it in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com