Stress whitening-resistant antibacterial polypropylene composition and preparation method thereof

A polypropylene composition and a stress-resistant technology are applied in the field of stress-whitening-resistant antibacterial polypropylene compositions and their preparation, and can solve the problems of poor stress-whitening resistance, poor mechanical properties of polymers, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

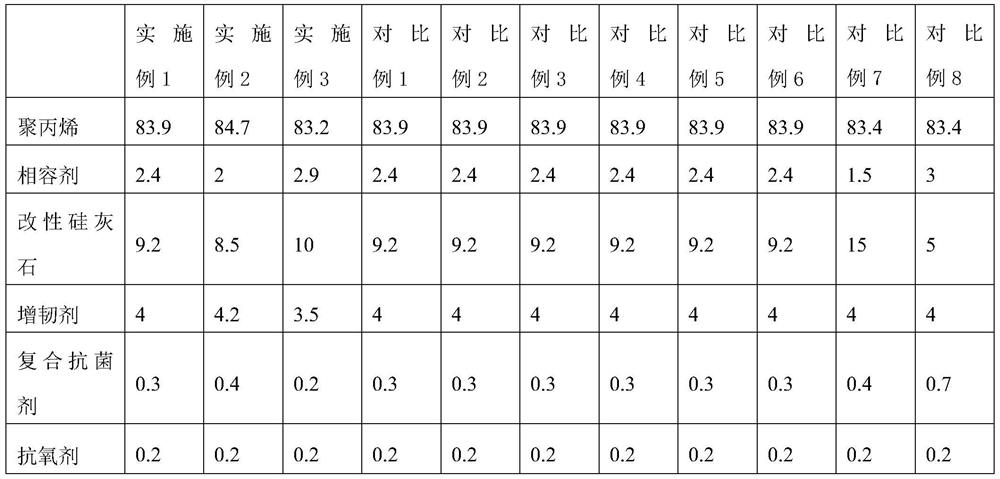

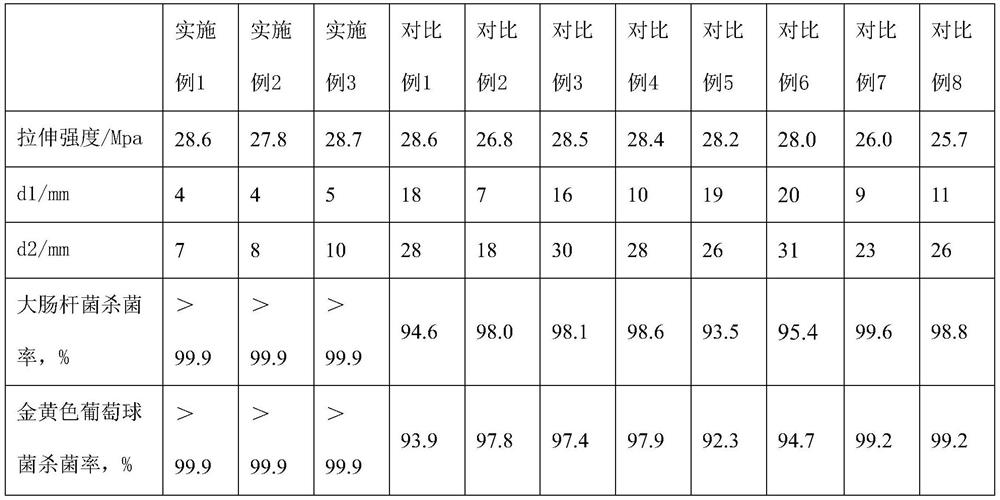

Embodiment 1、 comparative example 7 and comparative example 8

[0080] The polypropylene composition is prepared as follows:

[0081] 1) Preparation of composite antibacterial agent:

[0082] Add 5 parts by weight of nano-titanium dioxide, 2 parts by weight of nano-silver and 0.05 parts by weight of emulsifier into 20 parts by weight of distilled water, stir and emulsify, heat to 85-90 ° C, and add 30 parts by weight of 5 wt% cerium chloride aqueous solution dropwise , the dropping rate is 6 parts by weight / 10min, after the dropwise addition, 2 parts by weight of polypropylene glycol diglycidyl ether is added, then ultrasonicated at 70-80°C for 30min, centrifuged after 2h and washed 4 times with distilled water, after dehydration at 50 Drying at ℃ for 5 hours to obtain a composite antibacterial agent;

[0083] 2) Preparation of compatibilizer

[0084] 100 parts by weight of polypropylene A, 1 part by weight of maleic anhydride, 0.6 parts by weight of nano-titanium dioxide and 0.6 parts by weight of silane coupling agent are mixed uniform...

Embodiment 2

[0089] The polypropylene composition is prepared as follows:

[0090] 1) Preparation of composite antibacterial agent:

[0091] Add 4.8 parts by weight of nano-titanium dioxide, 1.5 parts by weight of nano-silver and 0.05 parts by weight of emulsifier into 20 parts by weight of distilled water, stir and emulsify, heat to 85-90 ° C, add 35 parts by weight of 4 wt% cerium chloride aqueous solution dropwise, The dropping rate is 7 parts by weight / 10min. After the addition is completed, 1.7 parts by weight of polypropylene glycol diglycidyl ether is added, then ultrasonicated at 70-80°C, centrifuged after 1h and washed with distilled water for 4 times, and dehydrated at a temperature of 60°C Under drying for 6 hours, a composite antibacterial agent is obtained;

[0092] 2) Preparation of compatibilizer

[0093] 100 parts by weight of polypropylene A, 1.1 parts by weight of maleic anhydride, 0.5 parts by weight of nano-titanium dioxide and 0.8 parts by weight of silane coupling a...

Embodiment 3

[0098] The polypropylene composition is prepared as follows:

[0099] 1) Preparation of composite antibacterial agent:

[0100] Add 5.3 parts by weight of nano-titanium dioxide, 2.3 parts by weight of nano-silver and 0.1 part by weight of emulsifier into 25 parts by weight of distilled water, stir and emulsify, heat to 85-90 ° C, add dropwise 30 parts by weight of 5 wt% cerium chloride aqueous solution, The dropping rate is 5 parts by weight / 10min. After the addition is completed, add 2.1 parts by weight of polypropylene glycol diglycidyl ether, then sonicate at 70-80°C, centrifuge after 2 hours and wash with distilled water for 3 times, and dehydrate at 50°C Under drying for 5 hours, the compound antibacterial agent was obtained;

[0101] 2) Preparation of compatibilizer

[0102] 100 parts by weight of polypropylene A, 0.8 parts by weight of maleic anhydride, 0.8 parts by weight of nano-titanium dioxide and 0.5 parts by weight of silane coupling agent are mixed uniformly, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com