Method for manufacturing high-integration microarray LED packaging module

A technology of LED packaging and manufacturing methods, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of process complexity, high junction temperature, and affecting heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

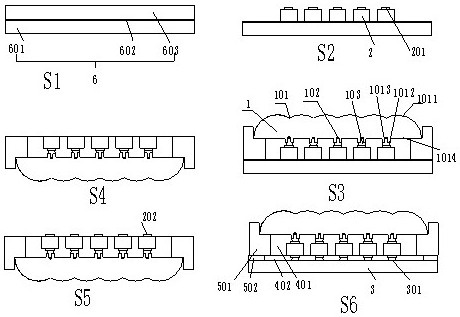

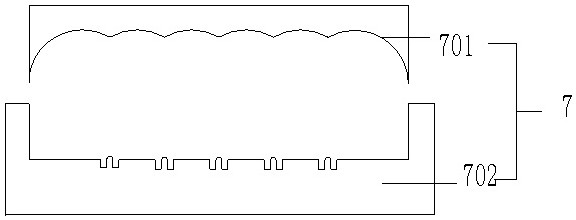

[0036] figure 1 It is a schematic diagram of the manufacturing process of the highly integrated microarray LED packaging module of the embodiment of the present invention, and the specific steps are as follows:

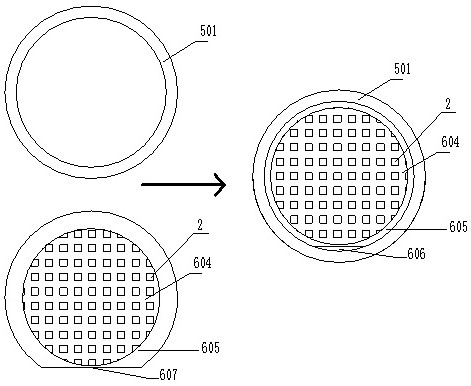

[0037] S1, providing LED prefabricated parts, including microarray lens cover plate 1, epitaxial wafer 6, microarray lens cover plate 1 includes microarray lens 101, metal wiring layer 102 and electrode pad 103; epitaxial wafer 6 includes substrate 601, buffer Layer 602 and epitaxial layer 603. In this embodiment, the size of the epitaxial wafer is preferably 4 inches, that is, the diameter is 100 mm. The edge area of the epitaxial wafer 6 is provided with a mounting area 605. The epitaxial wafer 6 is cleaned ultrasonically by acetone, ethanol or deionized water. surface.

[0038] S2, performing array processing on the epitaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com