Preparation method of indium selenide/titanium dioxide nanosheet composite material

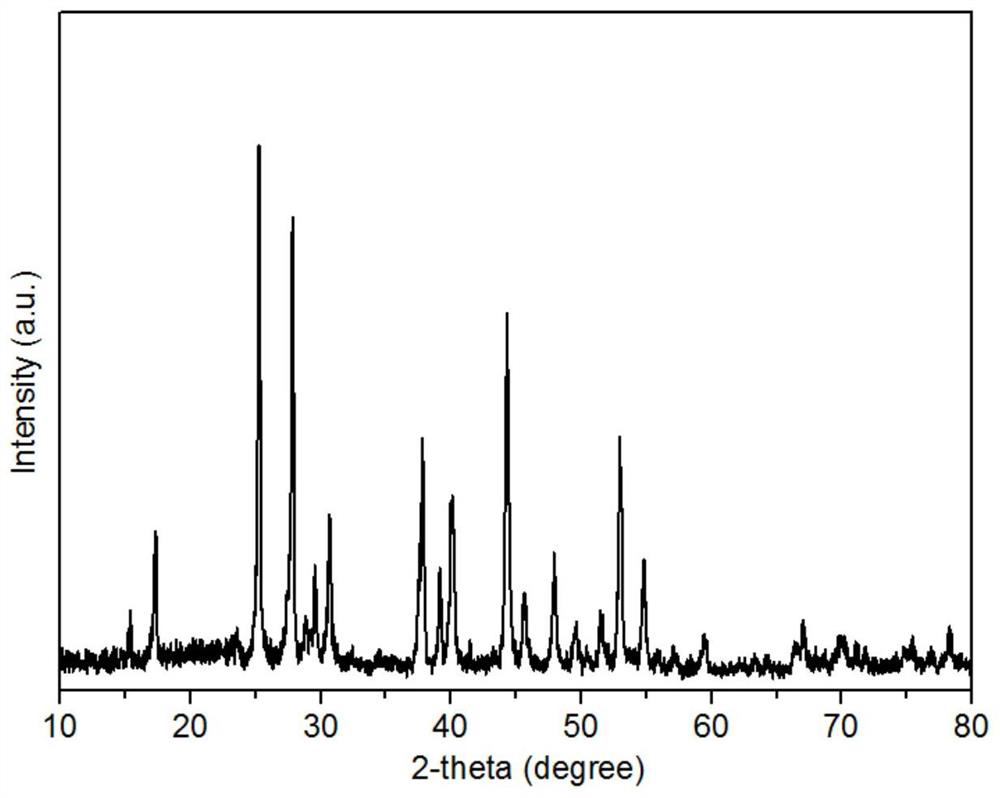

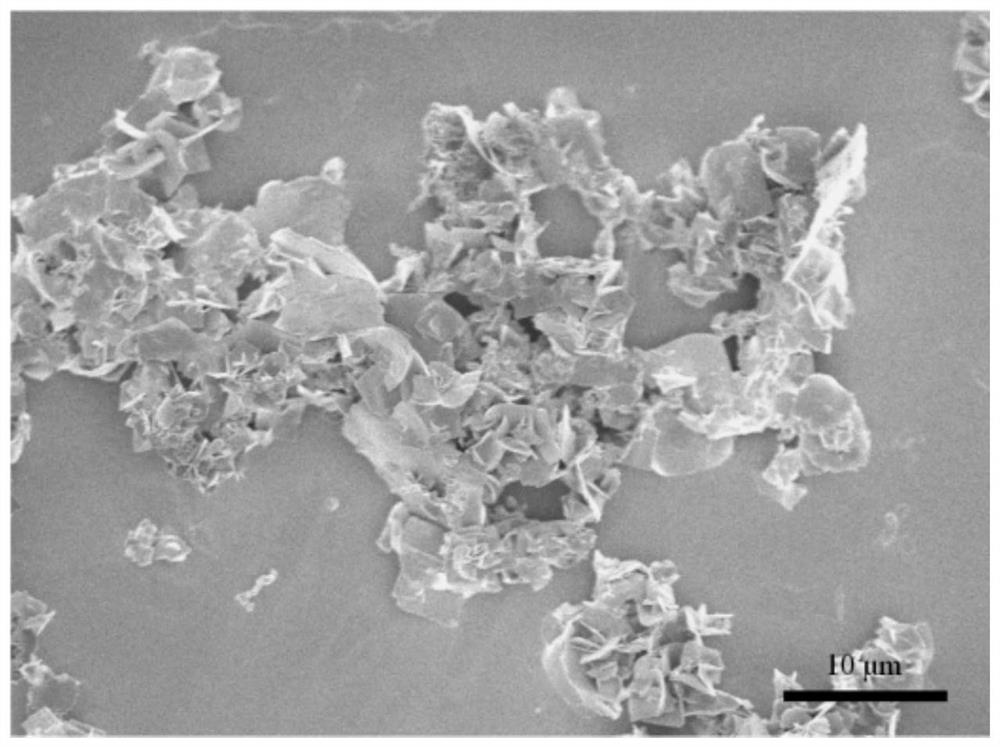

A composite material and titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as low efficiency, high process requirements, and complicated preparation methods, and achieve good crystallinity, The effect of high purity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a controllable preparation method of indium selenide / titanium dioxide nanosheet composite material, comprising the following steps:

[0025] Step 1, preparing an indium selenide precursor by a hydrothermal method;

[0026] Put 1mmol of indium acetate and 40mL of water into the reaction kettle, stir until the indium acetate is completely dissolved, then add 1mmol of selenium powder, stir until evenly dispersed, then add 40mL of ethylenediamine, react at 140°C for 40h, cool to room temperature after the reaction, After being collected by centrifugation, they were washed with ethanol and water in sequence, and freeze-dried to obtain the precursor powder.

[0027] Step 2, carrying out in-situ hydrolysis of n-butyl titanate on the precursor;

[0028] The indium selenide precursor was ultrasonically dispersed in 50 mL of absolute ethanol, 0.1 mmol of n-butyl titanate was added under nitrogen protection, and then 7 μL of water was added under stirring...

Embodiment 2

[0032] This embodiment provides a controllable preparation method of indium selenide / titanium dioxide nanosheet composite material, comprising the following steps:

[0033] Step 1, preparing an indium selenide precursor by a hydrothermal method;

[0034] Put 2mmol of indium acetate and 50mL of water into the reaction kettle, stir until the indium acetate is completely dissolved, then add 3mmol of selenium powder, stir until it is evenly dispersed, then add 20mL of ethylenediamine, react at 150°C for 50h, cool to room temperature after the reaction, After being collected by centrifugation, they were washed with ethanol and water in sequence, and freeze-dried to obtain the precursor powder.

[0035] Step 2, carrying out in-situ hydrolysis of n-butyl titanate on the precursor;

[0036] The indium selenide precursor was ultrasonically dispersed in 80 mL of absolute ethanol, 0.3 mmol of n-butyl titanate was added under nitrogen protection, and then 15 μL of water was added under s...

Embodiment 3

[0041] This embodiment provides a method for controlling the preparation of an indium selenide / titanium dioxide nanosheet composite material, comprising the following steps:

[0042] Step 1, preparing an indium selenide precursor by a hydrothermal method;

[0043] Put 3mmol of indium acetate and 60mL of water into the reaction kettle, stir until the indium acetate is completely dissolved, add 4.5mmol of selenium powder, stir until evenly dispersed, add 30mL of ethylenediamine, react at 160°C for 65h, cool to room temperature after the reaction , collected by centrifugation, washed with ethanol and water in turn, and freeze-dried to obtain the precursor powder.

[0044] Step 2, carrying out in-situ hydrolysis of n-butyl titanate on the precursor;

[0045] The indium selenide precursor was ultrasonically dispersed in 100 mL of absolute ethanol, 0.5 mmol of n-butyl titanate was added under nitrogen protection, and then 30 μL of water was added under stirring to hydrolyze n-butyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com