Electrode wire for wire electric discharge machining and preparation method thereof

A technology of cutting processing and wire electric discharge, which is applied in the field of electrode wire for wire electric discharge cutting and its preparation, which can solve the problems of wire breakage during shutdown, ablation and scrapping of conductive blocks, accelerated mechanical wear of conductive blocks, large mechanical wear of conductive blocks, etc. problems, to achieve the effect of improving local electric field strength, reducing mechanical wear, and high processing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

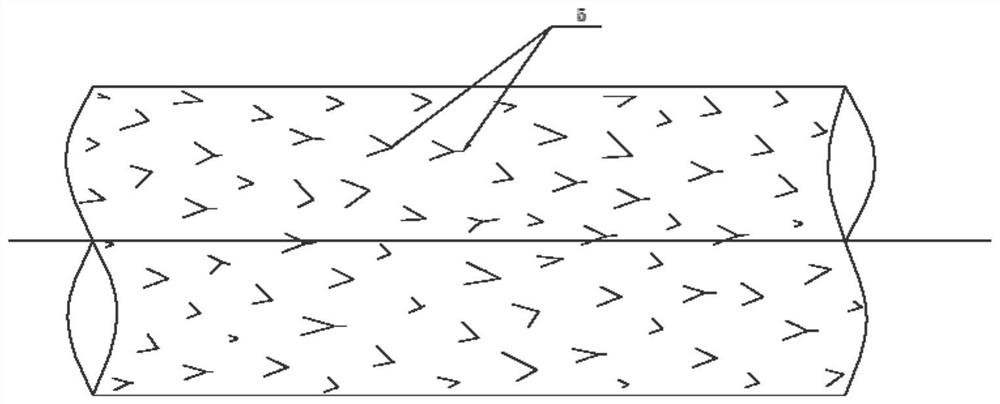

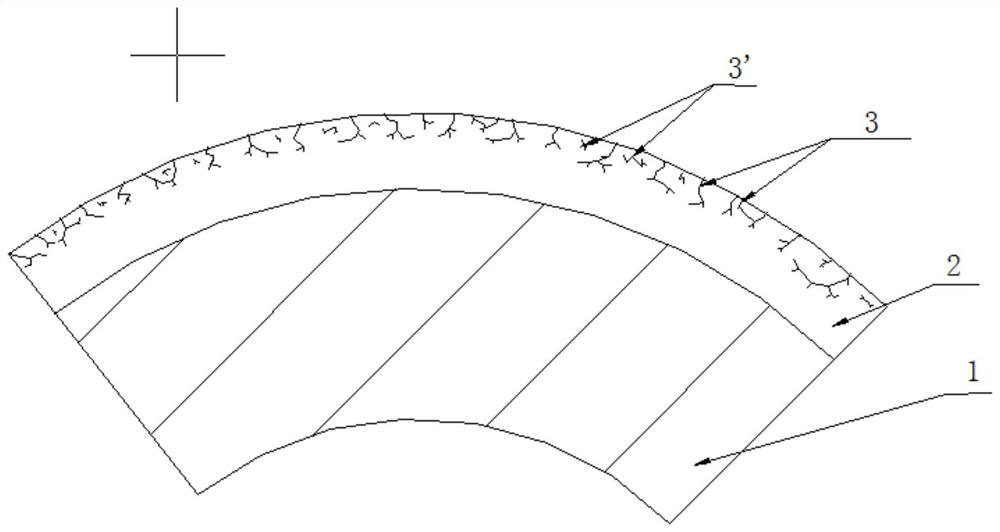

[0046] An electrode wire for wire electric discharge machining, which is prepared according to the following steps:

[0047] 1) Prepare a brass wire core with a diameter of 0.9mm;

[0048] 2) Electroplating or coating the above-mentioned wire core to obtain a galvanized bus bar, and the thickness of the galvanized layer is 5 μm;

[0049] 3) Perform the first low-temperature diffusion heat treatment on the above-mentioned galvanized bus bar. The heat treatment temperature is 150°C, the heat treatment time is 5h, the heating rate is 50°C / h, and the cooling rate is 120°C / h to form the first line with a brittle diffusion layer Blank, the diffusion layer is mainly composed of γ-phase copper-zinc alloy;

[0050] 4) Carry out metal plastic drawing processing on the first wire billet after the first diffusion heat treatment in step 3), the drawing size is 0.47mm, and the drawing rate is 300m / min, so that the brittle layer of the γ-phase copper-zinc alloy is broken and formed by The ...

Embodiment 2

[0056] An electrode wire for wire electric discharge machining, which is prepared according to the following steps:

[0057] 1) preparing a brass wire core with a diameter of 0.5mm;

[0058] 2) Electroplating or coating the above-mentioned wire core to obtain a galvanized busbar, and the thickness of the galvanized layer is 2 μm;

[0059] 3) Perform the first low-temperature diffusion heat treatment on the above-mentioned galvanized bus bar, the heat treatment temperature is 100°C, the heat treatment time is 2h, the heating rate is 60°C / h, and the cooling rate is 100°C / h, forming the first line with a brittle diffusion layer Blank, the diffusion layer is mainly composed of γ-phase copper-zinc alloy;

[0060] 4) Carry out metal plastic drawing processing on the first wire blank after the first diffusion heat treatment in step 3), the drawing size is 0.30 mm, and the drawing rate is 400 m / min, so that the brittle layer of the γ-phase copper-zinc alloy is broken and formed by T...

Embodiment 3

[0064] An electrode wire for wire electric discharge machining, which is prepared according to the following steps:

[0065] 1) Prepare a brass wire core with a diameter of 2.0mm;

[0066] 2) Electroplating or coating the above-mentioned wire core to obtain a galvanized busbar, and the thickness of the galvanized layer is 20 μm;

[0067] 3) Perform the first low-temperature diffusion heat treatment on the above-mentioned galvanized busbar. The heat treatment temperature is 250°C, the heat treatment time is 10h, the heating rate is 100°C / h, and the cooling rate is 60°C / h to form the first line with a brittle diffusion layer Blank, the diffusion layer is mainly composed of γ-phase copper-zinc alloy;

[0068] 4) Carry out metal plastic drawing processing to the first wire blank after the first diffusion heat treatment in step 3), the drawing size is 0.80mm, and the drawing rate is 500m / min, so that the brittle layer of the γ-phase copper-zinc alloy is broken and formed by The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com