Sustained-release dust suppression microcapsule, and preparation method and application thereof

A microcapsule, slow-release technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to capture coal dust and difficulty in achieving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

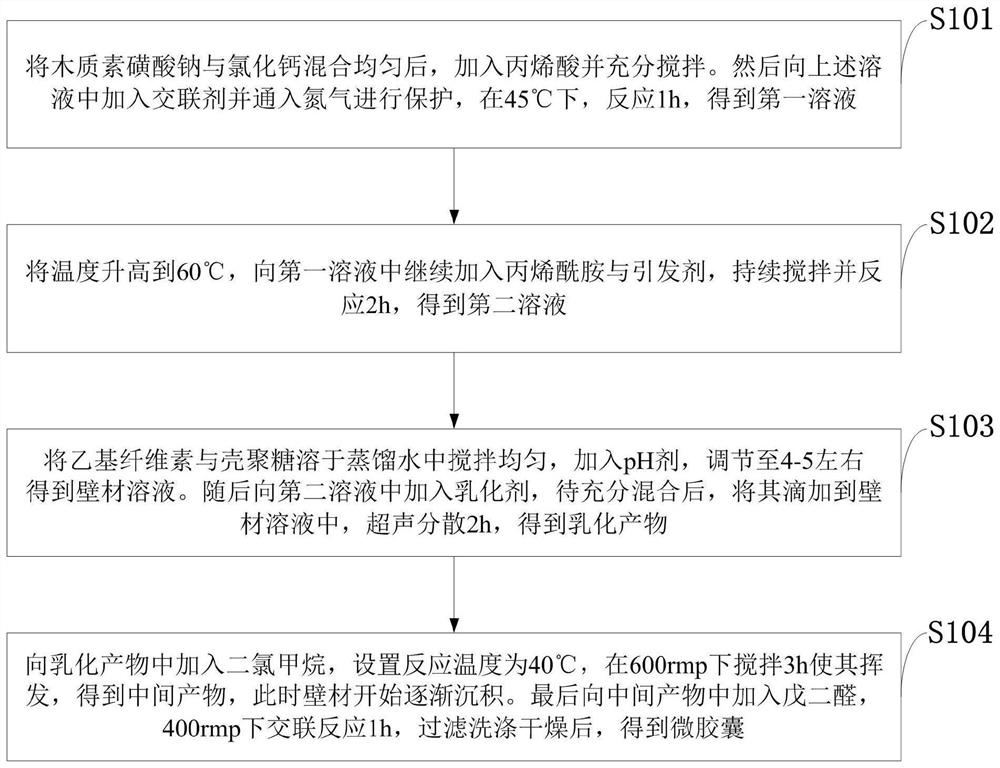

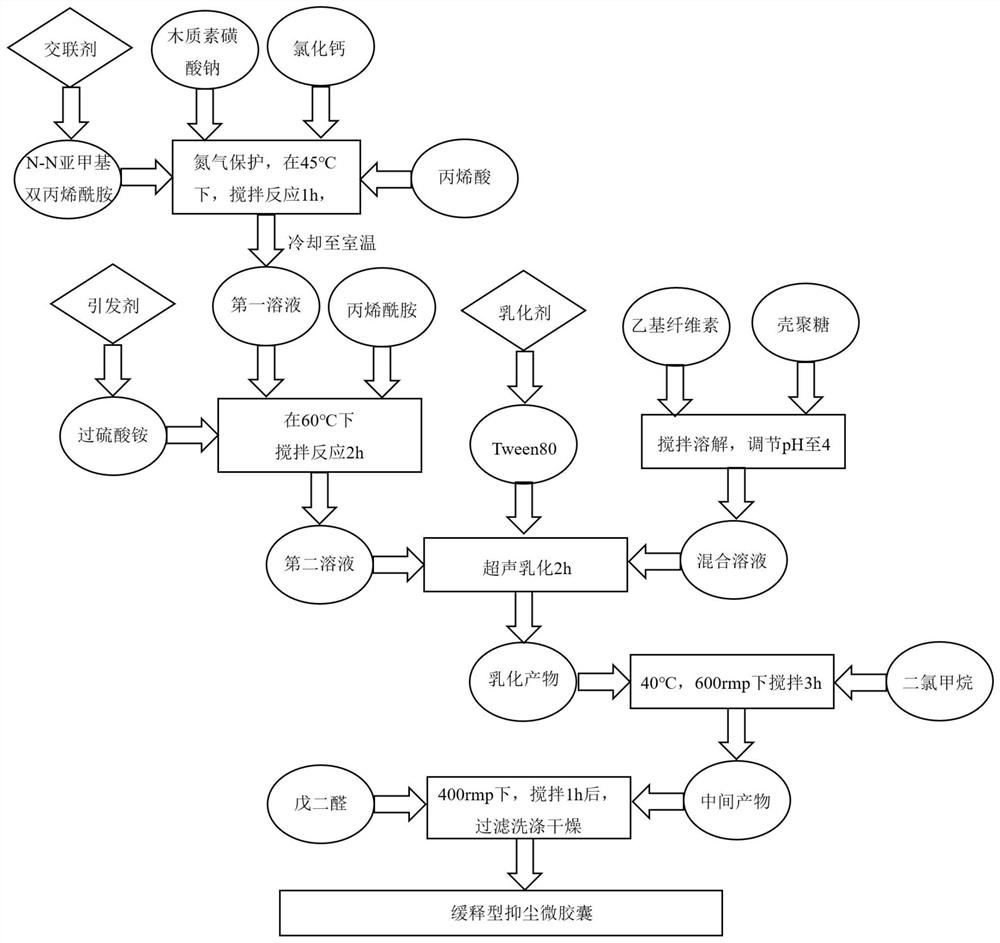

[0035]Such as figure 1 Shown, the preparation method of the sustained-release type dust-suppressing microcapsule provided by the invention comprises the following steps:

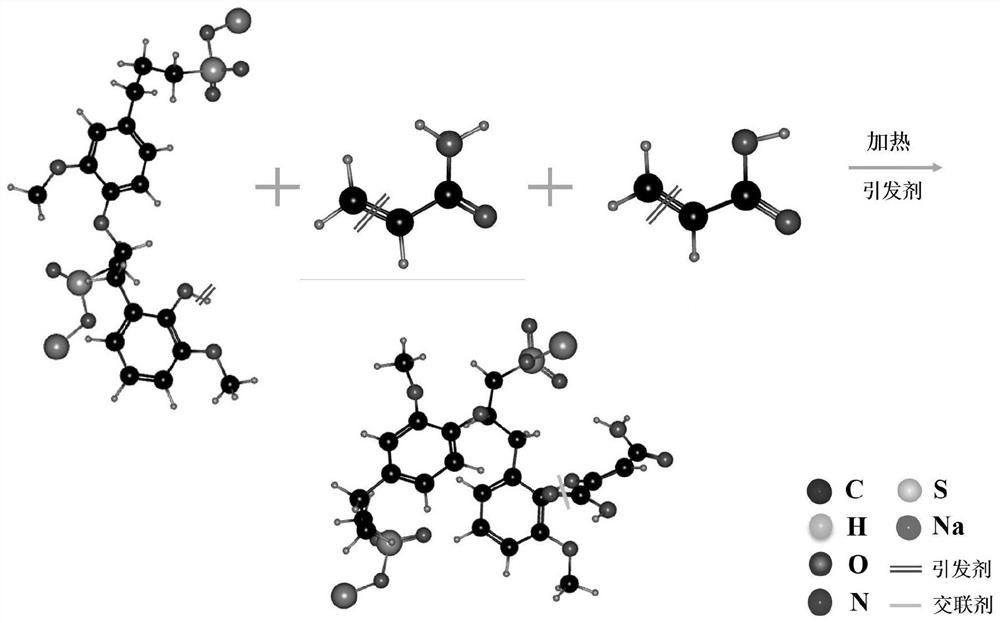

[0036] S101: After mixing sodium lignosulfonate and calcium chloride evenly, add acrylic acid and stir well. Then, a crosslinking agent was added to the above solution and protected by nitrogen gas, and reacted at 45° C. for 1 hour to obtain the first solution;

[0037] S102: raising the temperature to 60° C., continuing to add acrylamide and an initiator to the first solution, continuously stirring and reacting for 2 hours, to obtain a second solution;

[0038] S103: dissolving ethyl cellulose and chitosan in distilled water and stirring evenly, adding a pH agent, and adjusting it to about 4-5 to obtain a wall material solution. Then add an emulsifier to the second solution, and after being fully mixed, drop it into the wall material solution, ultrasonically disperse for 2 hours, and obtain an emulsified ...

Embodiment 1

[0046] The preparation method of the slow-release dust-suppressing microcapsules provided by the present invention comprises: weighing 2g of sodium lignosulfonate and adding it into a three-neck flask filled with 100ml of distilled water, then adding 0.1g of calcium chloride and mixing evenly, after fully dissolving, adding 6g of acrylic acid and 0.2g of N-N methylenebisacrylamide were stirred thoroughly, and nitrogen gas was passed into the three-necked flask, and stirred and reacted at 45°C for 1h. After it was cooled to room temperature, 7g of acrylamide and 0.1g of ammonium persulfate were added, the temperature was raised to 60°C, and the mixture was continuously stirred and reacted for 2 hours to obtain a core material solution. Dissolve 1g of ethyl cellulose and 1g of chitosan in 100ml of distilled water and stir evenly, then add glacial acetic acid to adjust the pH to 4. After fully mixed, add it dropwise to the core material solution, and take it out after ultrasonic d...

Embodiment 2

[0048] The preparation method of the slow-release dust-suppressing microcapsules provided by the present invention comprises: weighing 2g of sodium lignosulfonate and adding it into a three-neck flask filled with 100ml of distilled water, then adding 0.1g of calcium chloride and mixing evenly, after fully dissolving, adding 6g of acrylic acid and 0.2g of N-N methylenebisacrylamide were stirred thoroughly, and nitrogen gas was passed into the three-necked flask, and stirred and reacted at 45°C for 1h. After it was cooled to room temperature, 7g of acrylamide and 0.1g of ammonium persulfate were added, the temperature was raised to 60°C, and the mixture was continuously stirred and reacted for 2 hours to obtain a core material solution. Dissolve 1g of ethyl cellulose and 2g of chitosan in 100ml of distilled water and stir evenly, then add glacial acetic acid to adjust the pH to 4. After fully mixed, add it dropwise to the core material solution, and take it out after ultrasonic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com