A kind of hmfo@mofs composite material and its preparation method and application

A technology of composite materials and mixing temperature, applied in biochemical equipment and methods, fixed on/in organic carriers, fermentation, etc., can solve the problems of lack of structural properties and mechanisms, and achieve good stability and reusability performance, low energy consumption, and high enzyme loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation process of 5-hydroxymethylfurfural oxidase

[0036]1. Synthesize the 5-hydroxymethylfurfural oxidase gene (sequence list 1), and connect the 5-hydroxymethylfurfural oxidase gene to the pPICZa-A expression vector with restriction endonucleases XhoI and XbaI. Ligation was performed overnight with T4 ligase. Take 5 μL of the connection solution and transform it into Escherichia coli Top10, spread it on a resistance plate containing ampicillin and culture it overnight at 37°C for 12-15h. Pick 10 large and scattered single colonies on the ampicillin plate for colony PCR identification, analyze the products by agarose gel electrophoresis, continue to culture the colonies containing the target band, extract the plasmid, and perform sequencing analysis.

[0037] 2. Plasmid extraction: Centrifuge the bacterial solution at 5000rpm for 5min. Remove the supernatant and precipitate the plasmid with a plasmid kit.

[0038] The extracted plasmid was subjected to double ...

Embodiment 2

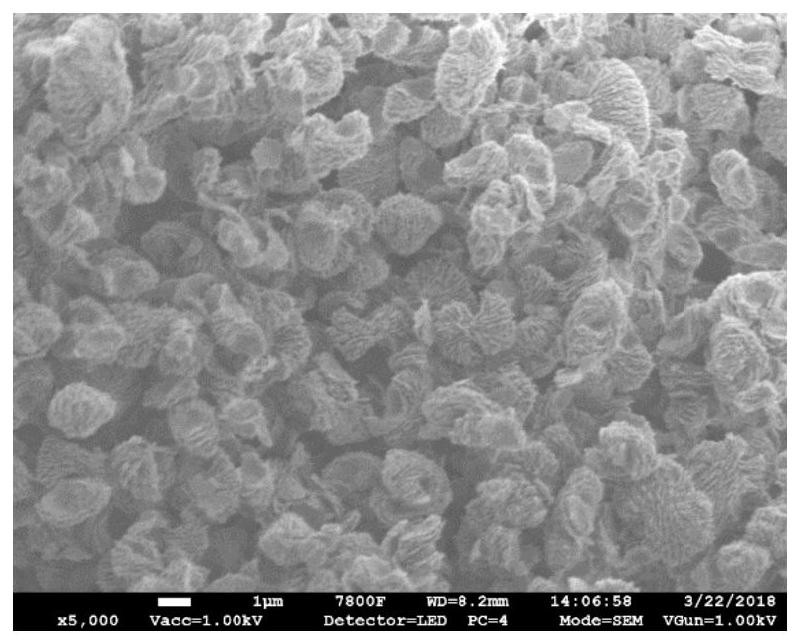

[0060] Preparation process of HMFO@MOFs

[0061] Take 2.0mL 2-methylimidazole (160.0mM) solution, add 0.5mL HMFO (1.0mg / mL) solution, mix evenly, add 2.0mL zinc acetate solution with a concentration of 40.0mM, stir at 25°C for 30min and let stand for 12h, the obtained The solid was washed 3 times with deionized water to obtain HMFO@MOFs.

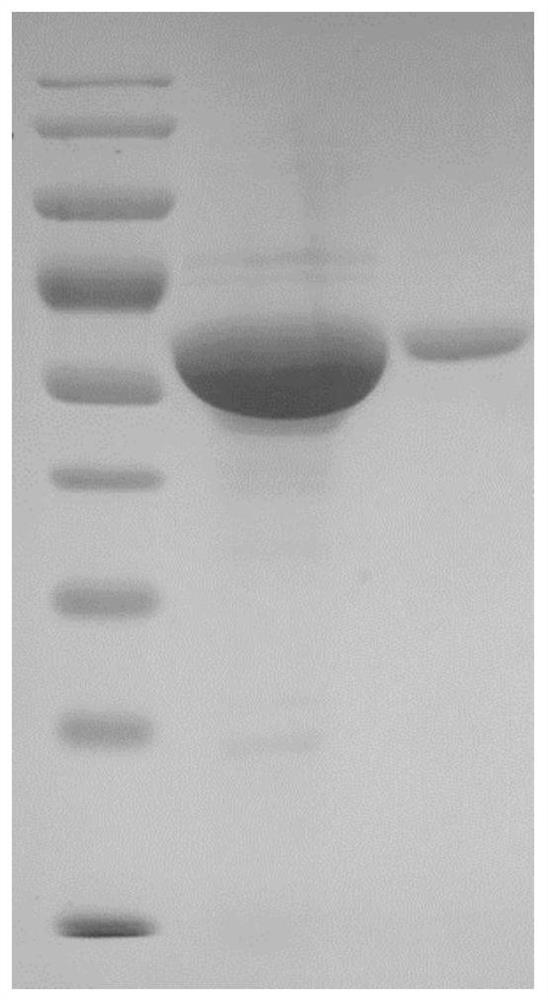

[0062] Add an appropriate amount of glacial acetic acid to dissolve the HMFO@MOFs prepared in Example 2, add a mixed solution of ethanol and acetone with a volume ratio of 1:1 according to the volume ratio of 4:1, place it at -20°C for 2 hours, centrifuge, discard the supernatant, and use Wash the precipitate three times with absolute ethanol, add 2.0% SDS to dissolve it ultrasonically, take 40 μL of protein solution and 10.0 μL of sample buffer (5×), mix well, boil for 10 min, and take the supernatant for SDS-PAGE determination ( Figure 4 , M is the standard protein molecule, band 1 is the supernatant during preparation, and band 2 is HMF...

Embodiment 3

[0067] Preparation process of HMFO@MOFs

[0068] Take 2.0mL of 2-methylimidazole (160.0mM) solution, add 0.5mL of HMFO (2.0mg / mL) solution, mix evenly, add 2.0mL of zinc acetate solution with a concentration of 40mM, stir at 25°C for 10min, and let stand for 18h to obtain The solid was washed 3 times with deionized water to obtain HMFO@MOFs.

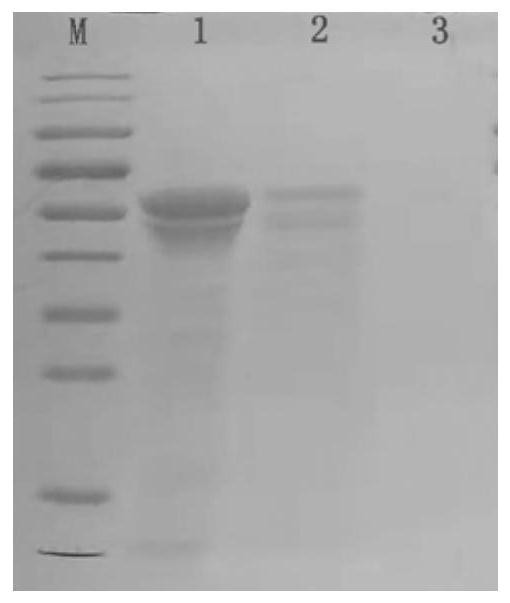

[0069] Add an appropriate amount of glacial acetic acid to dissolve the HMFO@MOFs prepared in Example 3, add a mixed solution of ethanol and acetone with a volume ratio of 1:1 according to the volume ratio of 4:1, place it at -20°C for 2 hours, centrifuge, discard the supernatant, and use Wash the precipitate three times with absolute ethanol, add 2.0% SDS to dissolve it ultrasonically, take 40 μL of protein solution and 10.0 μL of sample buffer (5×), mix well, boil for 10 min, and take the supernatant for SDS-PAGE determination ( Figure 6 , M is the standard protein molecule, band 1 is the supernatant during preparation, band 2 is HMF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com