Antibacterial low-barrier melt-blown non-woven fabric and preparation method thereof

A technology of melt-blown non-woven fabrics and inorganic nanoparticles, which is applied in the direction of melt spinning, non-woven fabrics, rayon manufacturing, etc., and can solve the problems of not inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation method of antibacterial low-resistance meltblown non-woven fabric

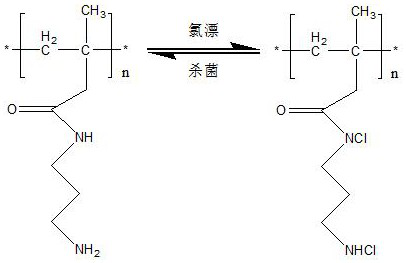

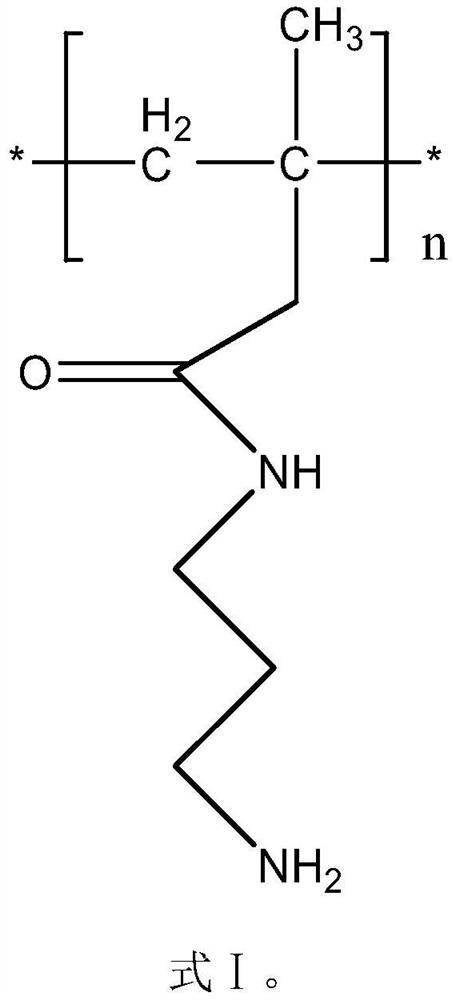

[0031] S1. Preparation method of modified polypropylene: firstly mix 100g polypropylene, 70g N-(3-aminopropyl)acrylamide monomer and 0.1g azobisisobutyronitrile uniformly, and then feed the screw extruder , Heated to 220 ℃ to melt, graft copolymerization occurs, extruded by the extruder and cooled, and finally cut into uniform modified polypropylene, the chemical structure is shown in formula I;

[0032]

Embodiment 2

[0033] Example 2 Preparation method of antibacterial low resistance meltblown non-woven fabric

[0034] S1. Preparation method of modified polypropylene: firstly mix 100g polypropylene, 120g N-(3-aminopropyl)acrylamide monomer and 1g tert-butyl hydroperoxide uniformly, and then feed the screw extruder. Melt under the condition of heating to 250°C, graft copolymerization occurs, extruded from the extruder and cooled, and finally cut into uniform modified polypropylene;

[0035] S2. Preparation of ultra-fine fibers: 200g of modified polypropylene, 40g of glass fiber, and 30g of graphene oxide sol are heated and melted, and the melting temperature is 1200℃. After the mixture is uniform, it is sprayed out from the capillary spinneret. After down-drawing, the continuous ultra-fine fiber with an average fiber diameter of 5μm and a diameter distribution of 3.5-6μm is produced;

[0036] S3. Preparation of melt blown cloth: the ultra-fine fibers sprayed from the capillary spinneret are drawn...

Embodiment 3

[0039] Example 3 Preparation method of antibacterial low resistance meltblown non-woven fabric

[0040] S1. Preparation method of modified polypropylene: firstly mix 100g polypropylene, 100g N-(3-aminopropyl)acrylamide monomer and 0.5g potassium persulfate uniformly, then feed into screw extruder and heat to Melt at 235°C, graft copolymerization takes place, extruded from the extruder and cooled, and finally cut into uniform modified polypropylene;

[0041] S2. Preparation of ultra-fine fibers: heat and melt 150g of modified polypropylene, 30g of glass fiber, and 22g of graphene oxide sol at a melting temperature of 1100°C. After mixing uniformly, it will be ejected from the capillary spinneret and exposed to hot air. After down-drawing, the continuous ultra-fine fibers with an average fiber diameter of 4.5 μm and a diameter distribution of 3.5-6 μm are produced;

[0042] S3. Preparation of melt blown cloth: the ultra-fine fibers sprayed from the capillary spinneret are drawn by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com