High-capacitance carbon fiber electrode material as well as preparation method and application thereof

A technology of carbon fiber electrodes and carbon materials, applied in supercapacitor pseudocapacitive electrode materials and their preparation, high capacitance carbon fiber electrode materials and their preparation fields, can solve problems such as the performance impact of electrochemical supercapacitors, and achieve large-scale production , The preparation process is simple, and the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

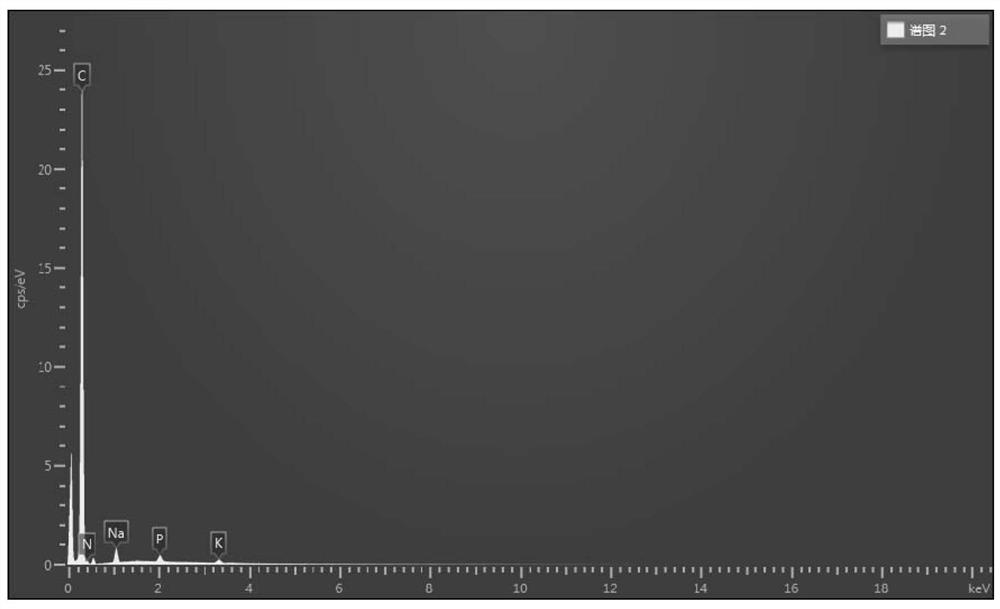

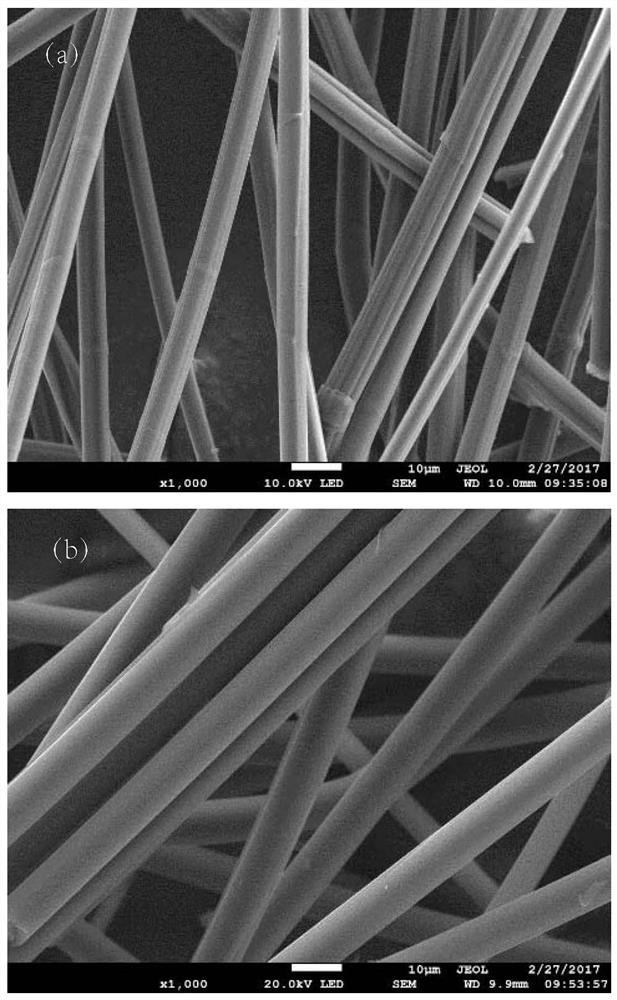

[0035] High-capacity nitrogen-doped conductive fibrous carbon material, sample synthesis:

[0036] Weigh the aramid fiber 1414; put it into a tube furnace to carry out pre-sintering, nitriding treatment (heat treatment) and carbonization treatment in sequence. First set the sintering temperature curve in an argon-protected furnace to increase the temperature from room temperature to 500° C. and keep the temperature for 2 hours. and then transferred to the NH 3 In a protected furnace, set the sintering temperature profile to heat treatment at 500-800° C. for 3 hours. Finally, the sintering temperature curve was set to be kept at 800° C. for 9 hours in an argon-protected furnace, and then cooled to room temperature in an argon atmosphere for 5 hours. According to the curve set above, the heating, constant temperature, and cooling processes are carried out to prepare a high-capacity nitrogen-doped conductive fiber carbon material.

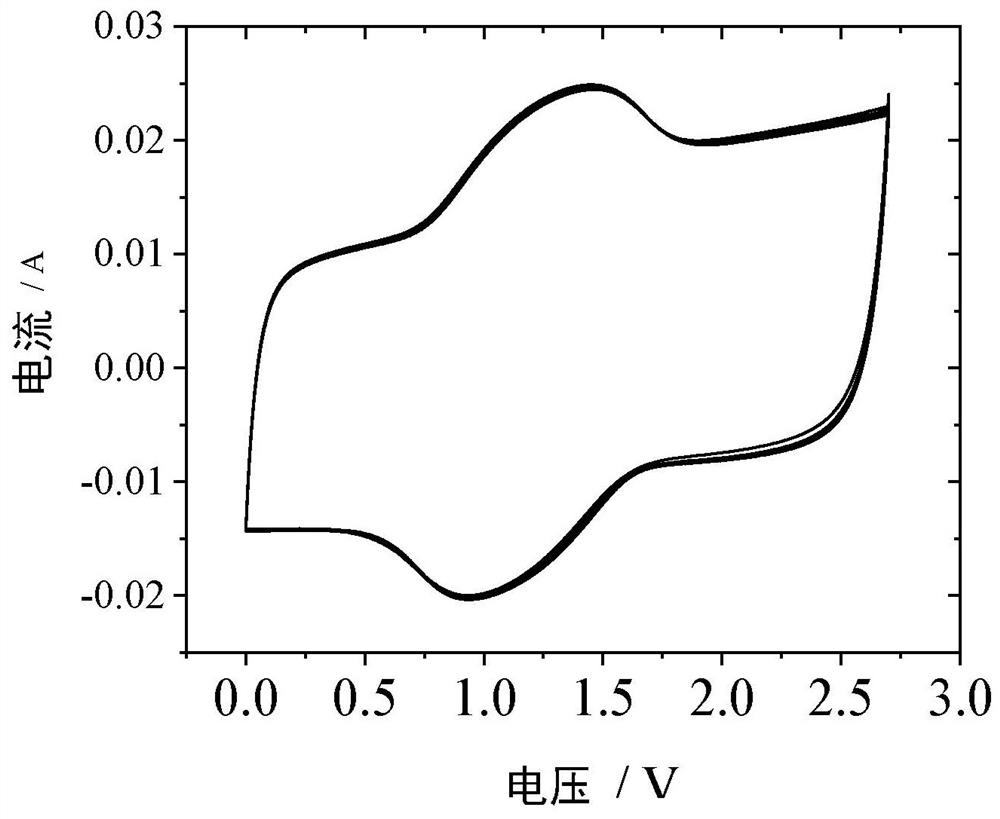

[0037] The preparation of supercapacitor: be...

Embodiment 2

[0043] High-capacity nitrogen-doped conductive fibrous carbon material, sample synthesis:

[0044] Weigh the polyester; put it into a tube furnace to carry out pre-sintering, nitriding treatment (heat treatment) and carbonization treatment in sequence. First set the sintering temperature curve in an argon-protected furnace to increase the temperature from room temperature to 600° C. and keep the temperature for 4 hours. then transfer to NH 3 In the protected furnace, the sintering temperature curve was set to raise the temperature to 600-800° C. and keep the temperature for 3 hours. Finally, the sintering temperature curve was set to 800° C. for 9 hours in an argon-protected furnace, and the temperature was lowered to room temperature in an argon atmosphere for 5 hours. According to the curve set above, the heating, constant temperature, and cooling processes are carried out to prepare a high-capacity nitrogen-doped conductive fiber carbon material. The carbon electrode sup...

Embodiment 3

[0046] High-capacity nitrogen-doped conductive fiber carbon material, sample synthesis;

[0047] Weigh the vinylon; put it into a tube furnace to carry out pre-sintering, nitriding treatment (heat treatment) and carbonization treatment in sequence. First set the sintering temperature curve in an argon-protected furnace to increase the temperature from room temperature to 500° C. and keep the temperature for 2 hours. then in NH 3 The temperature was raised to 500-800° C. in a protected furnace and kept for 3 hours. Finally, it was transferred to a furnace protected by argon at a sintering temperature of 900° C. for 9 hours, and cooled to room temperature after 5 hours in an argon atmosphere. According to the curve set above, the heating, constant temperature, and cooling processes are carried out to prepare a high-capacity nitrogen-doped conductive fiber carbon material. The carbon electrode supercapacitor was prepared by using the obtained high-capacity nitrogen-doped condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com