Preparation method of lyophyllum decastes nutritional ingredient powder

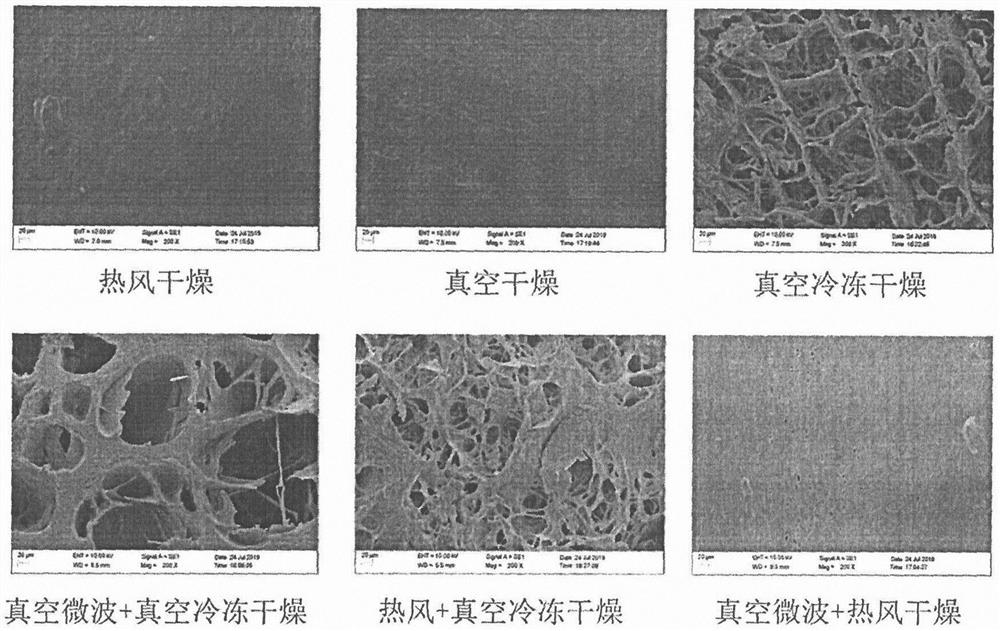

A technology for nutritional ingredients and antler mushrooms is applied in the field of development and utilization of edible fungus resources, which can solve the problems of neglecting the utilization of characteristic nutrients, lack of nutrient retention and regulation technology, etc. Shortening, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Cleaning and cutting of raw materials: select fresh and clean antler mushrooms with no pests, no rot, no mechanical damage, and no deformities, wash until the surface is free of impurities, and cross-cut mushroom slices to 3mm;

[0023] (2) Vacuum microwave pre-drying: place the above-mentioned mushroom slices in a vacuum microwave drying chamber, with an emission power of 6W / g, a rotating speed of 600r / min, a vacuum degree of 90KPa, and a microwave time of 4min, and dry to a moisture content of 40%;

[0024] (3) Vacuum freeze-drying: vacuum freeze-drying, cold trap temperature -45°C, vacuum degree 50Pa, dry for 20h to moisture content 3%;

[0025] (4) Coarse powder preparation: after the dried antler mushroom slice pulverizer is pulverized, cross a 60-mesh sieve to obtain antler mushroom coarse powder;

[0026] (5) Superfine pulverization: Vibrating low-temperature superfine pulverization of the antler mushroom powder, controlling the powder temperature below 40°C,...

Embodiment 2

[0030] (1) Cleaning and cutting of raw materials: select fresh and clean antler mushrooms with no pests, no rot, no mechanical damage, and no deformities, wash until the surface is free of impurities, and cross-cut mushroom slices to 8mm;

[0031] (2) Vacuum microwave pre-drying: place the above-mentioned mushroom slices in a vacuum microwave drying chamber, with an emission power of 2W / g, a rotating speed of 400r / min, a vacuum degree of 80KPa, and a microwave time of 2min, and dry to a moisture content of 60%;

[0032] (3) Vacuum freeze-drying: vacuum freeze-drying, cold trap temperature -45°C, vacuum degree 40-50Pa, dry for 15h to moisture content 5%;

[0033] (4) Coarse powder preparation: after the dried velvet mushroom sheet pulverizer is pulverized, cross a 30-mesh sieve to obtain velvet mushroom coarse powder;

[0034] (5) Ultra-fine grinding: Vibration-type ultra-fine grinding is performed on the coarse powder of antler mushroom, the temperature of the powder is contro...

Embodiment 3

[0037] (1) Cleaning and cutting of raw materials: select fresh and clean antler mushrooms with no pests, no rot, no mechanical damage, and no deformities, wash until the surface is free of impurities, and cross-cut mushroom slices to 5mm;

[0038] (2) Vacuum microwave pre-drying: place the above-mentioned mushroom slices in a vacuum microwave drying chamber, with an emission power of 4W / g, a rotating speed of 500r / min, a vacuum degree of 90KPa, and a microwave time of 3min, and dry to a moisture content of 50%;

[0039] (3) Vacuum freeze-drying: vacuum freeze-drying, cold trap temperature -45°C, vacuum degree 50Pa, dry for 17h to moisture content 4%;

[0040] (4) Coarse powder preparation: after the dried velvet mushroom sheet pulverizer is pulverized, cross a 40-mesh sieve to obtain velvet mushroom coarse powder;

[0041] (5) Ultra-fine grinding: Vibration-type ultra-fine grinding is carried out on the coarse powder of antler mushroom, the temperature of the powder is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com