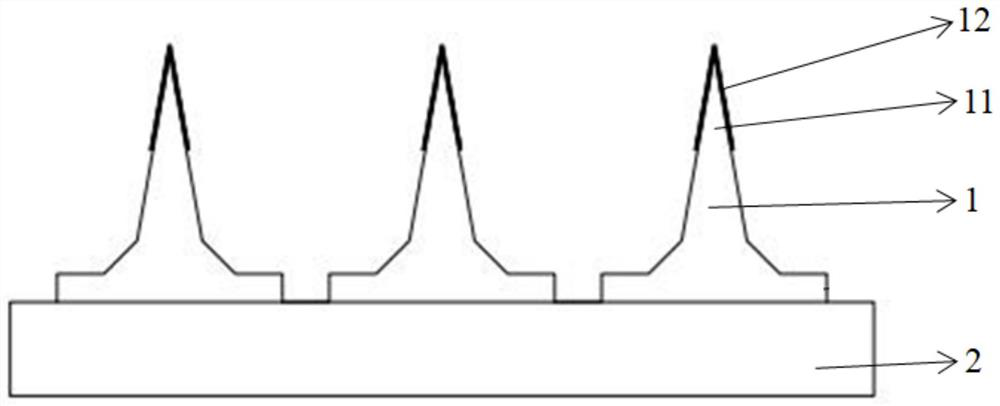

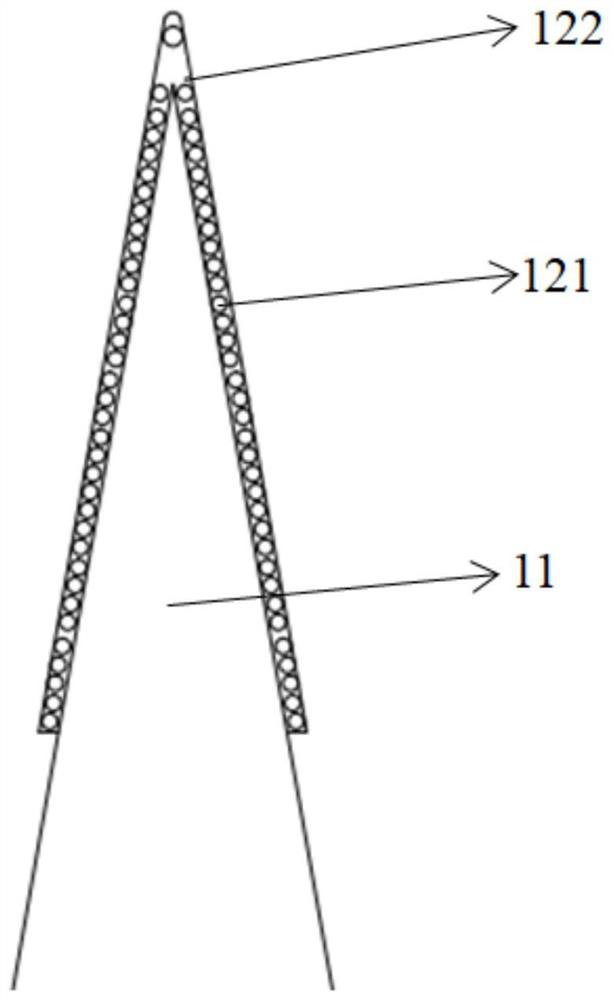

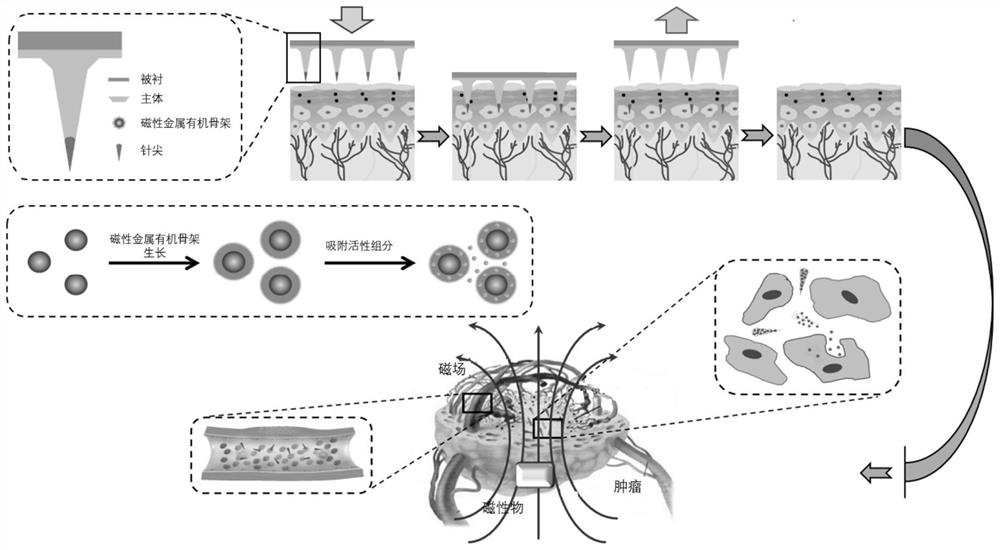

Magnetic control micro-needle robot as well as preparation method, use method and application thereof

A robot and microneedle technology, applied in the field of medicine, can solve the problems of not being able to meet the release requirements of a one-time large dose, not being able to perform skin puncture, and long treatment cycles, so as to avoid the first-pass effect, increase drug loading, and avoid Effects of drug wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0065] A magnetic iron-based metal-organic framework, the preparation method of which is as follows:

[0066] (1) Mix ferric nitrate and (trichloromethyl) carbonate (BTC), and react for 24 hours at 120° C. in a high-pressure reactor. The powder obtained after the solution is dried is washed with methanol for 24 hours, and dried to obtain an organometallic framework MOFs powder;

[0067] (2) The metalorganic framework MOFs powder, Fe3O4 nanoparticles and nickel nanoparticles (mass ratio 19:4:1) were mixed and stirred in methanol for 6 h, and then vacuum-dried at 80 °C to obtain magnetic iron-based metal organic skeleton.

preparation example 2

[0069] A magnetic iron-based metal-organic framework, the preparation method of which is as follows:

[0070] (1) From 1mmol of Fe 3+ (FeCl 3 , Fe(NO 3 ) 3 and Fe 2 (SO 4 ) 3 , the mass ratio is 1:1:1), 1mmol of H 2 BDC-OH in N,N'-dimethylformamide (DMF, 5 mL); the reactants were stirred for 5 min, then the resulting suspension was introduced into a Teflon-lined steel autoclave, and the temperature was set to Set at 150°C for three days; the light orange MIL-53(Fe)[DMF] powder was first washed with MeOH, and finally, after being dispersed in water and dried in air, MIL-53(Fe) was obtained.

[0071] (2) MIL-53(Fe) powder and Fe3O4 nanoparticles (mass ratio: 19:3) were mixed and stirred in methanol for 6 h, and then vacuum-dried at 80 °C to obtain a magnetic iron-based metal-organic framework.

preparation example 3

[0073] A magnetic iron-based metal-organic framework, the preparation method of which is as follows:

[0074] (1) by Fe 2+ (FeCl 2 , Fe(NO 3 ) 2 and Fe 2 (SO 4 ) 2 , mass ratio 1:1:1) (80mg, 0.40mmol) and H 4 DOBDC (40 mg, 0.20 mmol) was dissolved in a solution of N,N-dimethylformamide (3.7 mL), a mixture of 2-propanol (0.2 mL) and water (0.2 mL); sealed in a capped vial, And place it in a heating oven at 105°C for 24 hours to obtain dark brown needle-like crystals; after filtering, rinse the crystals thoroughly with methanol, and then dry them in air; the methanol-exchanged sample obtained after soaking once was placed in methanol for 24 hours , and then heated at 200 °C for 6 h under vacuum to obtain the Fe-based MOF.

[0075] (2) Fe-based metal-organic framework powder and nickel nanoparticles (mass ratio: 19:1) were mixed and stirred in methanol for 6 h, and then vacuum-dried at 80° C. to obtain a magnetic iron-based metal-organic framework.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com