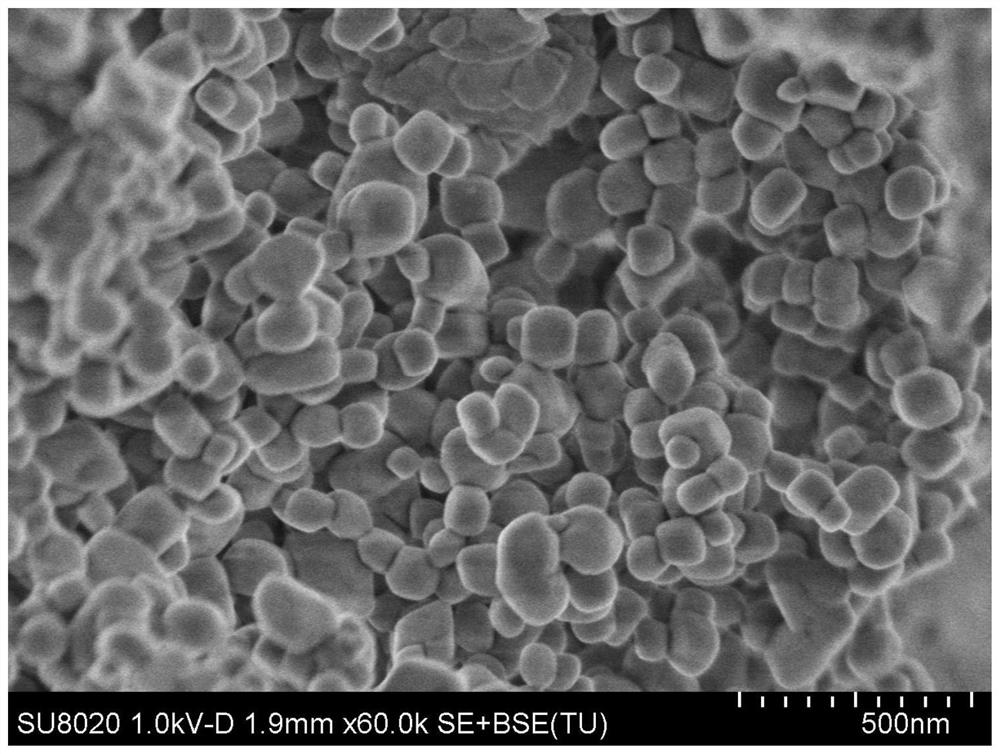

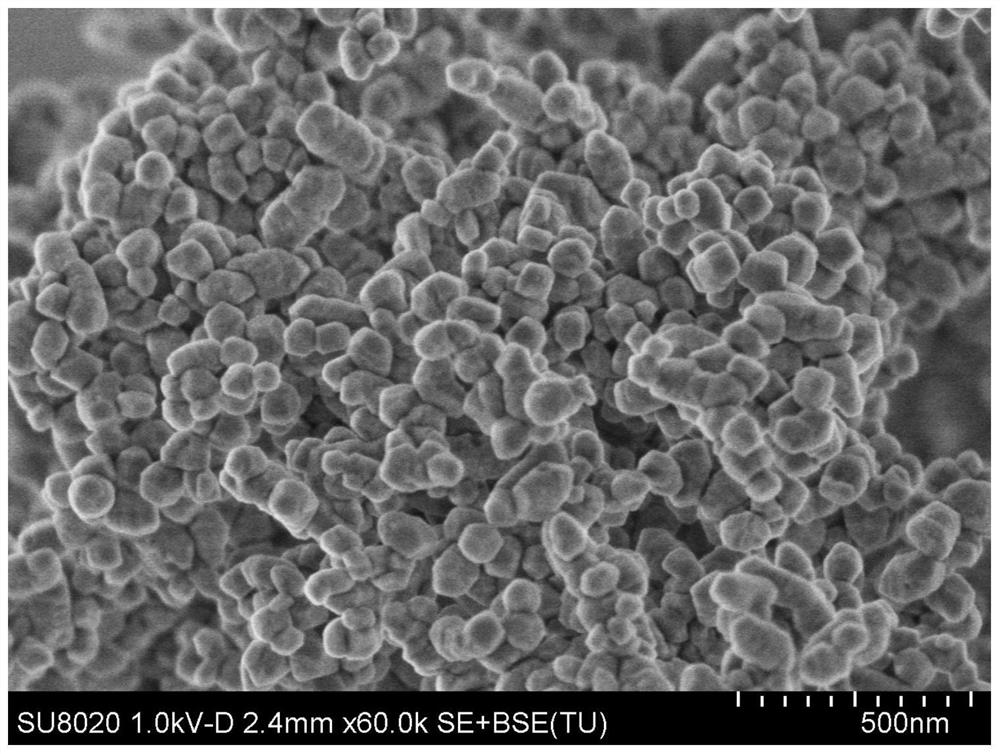

Preparation process of regular cubic crystal form nano calcium carbonate

A nano-calcium carbonate and preparation technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, chemical instruments and methods, etc., can solve the problems of irregular product particle shape, long carbonation reaction time, unstable quality, etc. , to achieve uniform and stable quality, short reaction time, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation process of regular cubic crystal nano-calcium carbonate belongs to the preparation of regular cubic crystal nano-calcium carbonate by carbonization of calcium hydroxide solution. The preparation method comprises the following steps:

[0028] (1) Lime digestion and calcium hydroxide slurry preparation: Lime and hot water at 70°C with a mass ratio of 1:5 are fully stirred and digested, aged and cooled properly, and the obtained lime slurry is sieved to remove large particles and impurities to obtain hydrogen The calcium oxide slurry is further refined through a suspension separator, and the calcium hydroxide slurry is adjusted to be cooled to room temperature to adjust the calcium hydroxide solid content to 10%;

[0029] (2) Addition of alkali metal ions: pump the adjusted calcium hydroxide slurry into the intermittent bubbling carbonization tower with stirring device, add sodium hydroxide as alkali metal ions, and adjust the concentration of sodium ions in...

Embodiment 2

[0035] The preparation process of regular cubic crystal nano-calcium carbonate belongs to the preparation of regular cubic crystal nano-calcium carbonate by carbonization of calcium hydroxide solution. The preparation method comprises the following steps:

[0036] (1) Lime digestion and calcium hydroxide slurry preparation: Lime and water at room temperature with a mass ratio of 1:8 are fully stirred and digested, aged and cooled properly, and the obtained lime slurry is sieved to remove large particles and impurities to obtain calcium hydroxide The slurry is further refined through a suspension separator, and the calcium hydroxide slurry is adjusted to be cooled to room temperature to adjust the calcium hydroxide solid content to 12%;

[0037] (2) Addition of alkali metal ions: pump the adjusted calcium hydroxide slurry into the intermittent bubbling carbonization tower with stirring device, add sodium bicarbonate as alkali metal ions, and adjust the concentration of sodium io...

Embodiment 3

[0043] The preparation process of regular cubic crystal nano-calcium carbonate belongs to the preparation of regular cubic crystal nano-calcium carbonate by carbonization of calcium hydroxide solution. The preparation method comprises the following steps:

[0044] (1) Lime digestion and calcium hydroxide slurry preparation: Lime and water at room temperature with a mass ratio of 1:9 are fully stirred and digested and properly aged and cooled, and the obtained lime slurry is sieved to remove large particles and impurities to obtain calcium hydroxide The slurry is further refined through a suspension separator, and the calcium hydroxide slurry is adjusted to be cooled to room temperature to adjust the calcium hydroxide solid content to 11%;

[0045] (2) Addition of alkali metal ions: pump the adjusted calcium hydroxide slurry into the intermittent bubbling carbonization tower with a stirring device, add sodium bicarbonate as alkali metal ions, and adjust the concentration of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com