Supramolecular polymer as well as preparation method and application thereof

A technology of supramolecular polymers and compounds, applied in the field of supramolecular polymer light-emitting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

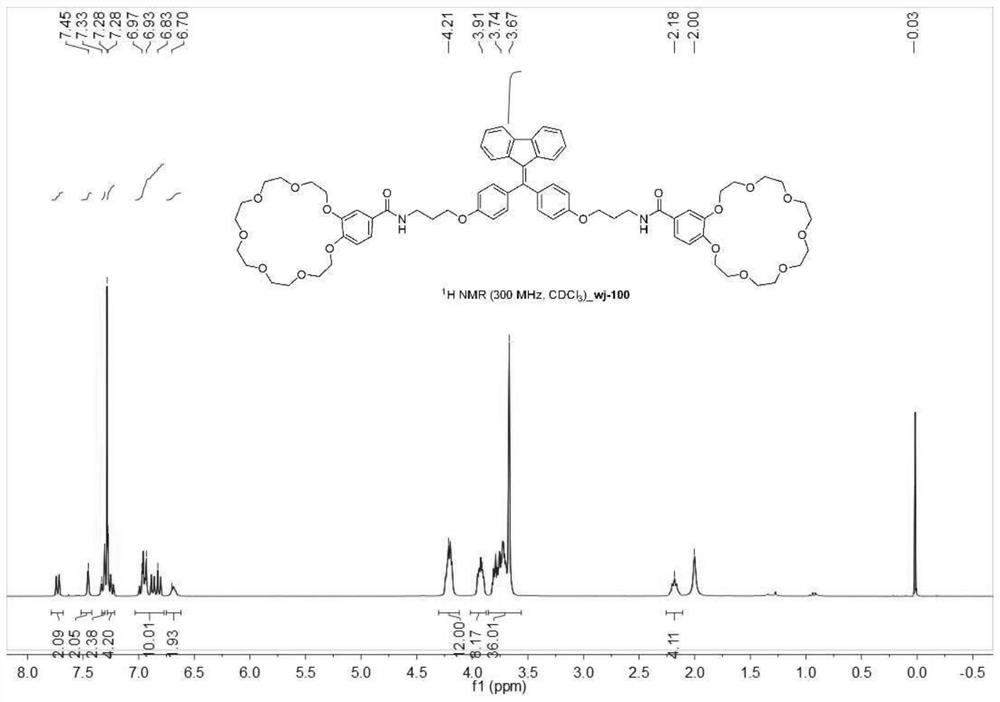

[0071] (1) Synthesis of host compound H:

[0072] a) Synthesis of Compound 1

[0073] In a 50 mL two-necked flask, add hexaethylene glycol (2.54 g, 8.8 mmol), p-toluenesulfonyl chloride (4.05 g, 21.2 mmol), 10 mg of 4-dimethylaminopyridine, and 20 mL of dichloromethane, and stir to dissolve. Under the ice-salt bath, triethylamine (4.37 g, 43.2 mmol) was slowly added dropwise with a constant pressure dropping funnel, and stirred at room temperature for 12 h after the dropwise addition was completed. After the TLC spot plate reaction is complete, stop stirring and post-treatment. Wash with 50mL of 1M hydrochloric acid aqueous solution, saturated sodium bicarbonate aqueous solution (50mL×1), saturated sodium chloride aqueous solution (50mL×1), dry over anhydrous sodium sulfate, filter, rotary evaporate, and wet load. Column chromatography eluent (eluent PE:DCM=5:1→3:1→1:1) gave 4.00 g of compound 1 as a colorless viscous liquid with a yield of 75%.

[0074] b) Synthesis of Com...

Embodiment 2~6

[0097] The synthesis of Compound H and Compound G is the same as in Example 1. Preparation of supramolecular polymer: Mix the host compound H and the secondary ammonium salt guest G in molar amounts of 1:2.0, 1:2.1, 1:2.3, 1:2.4, 1:2.5 equivalents, dissolve in chloroform: acetonitrile by volume ratio In a 1:1 solvent, sonicate for 10 minutes and let stand for 24 hours. The obtained material is difficult to process, and the luminous effect is not as good as that prepared in Example 1.

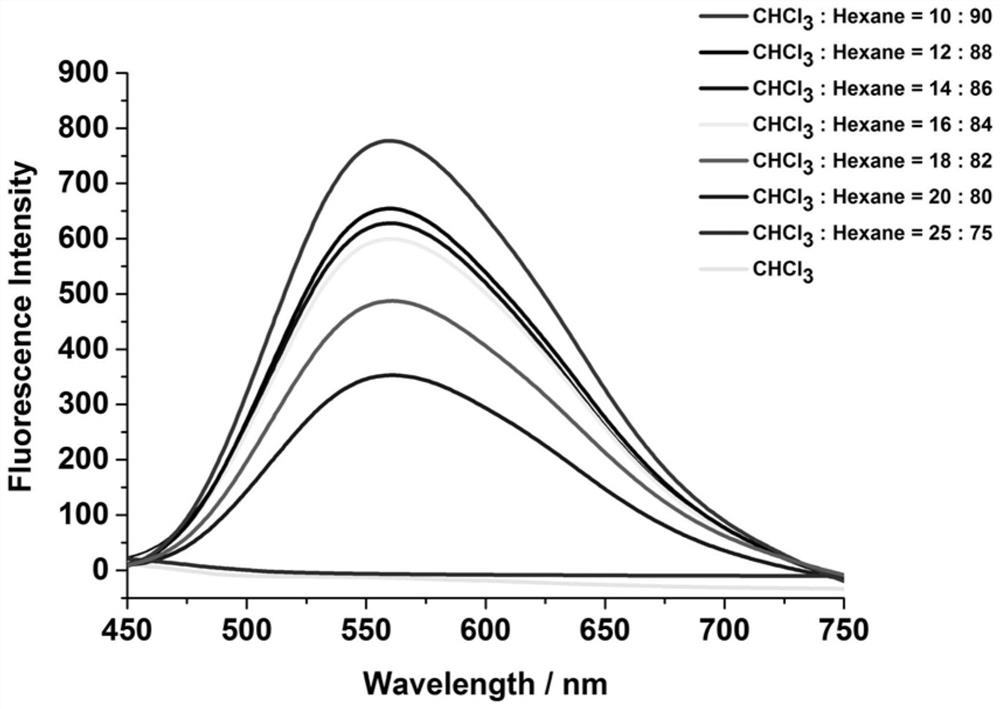

Embodiment 7~8

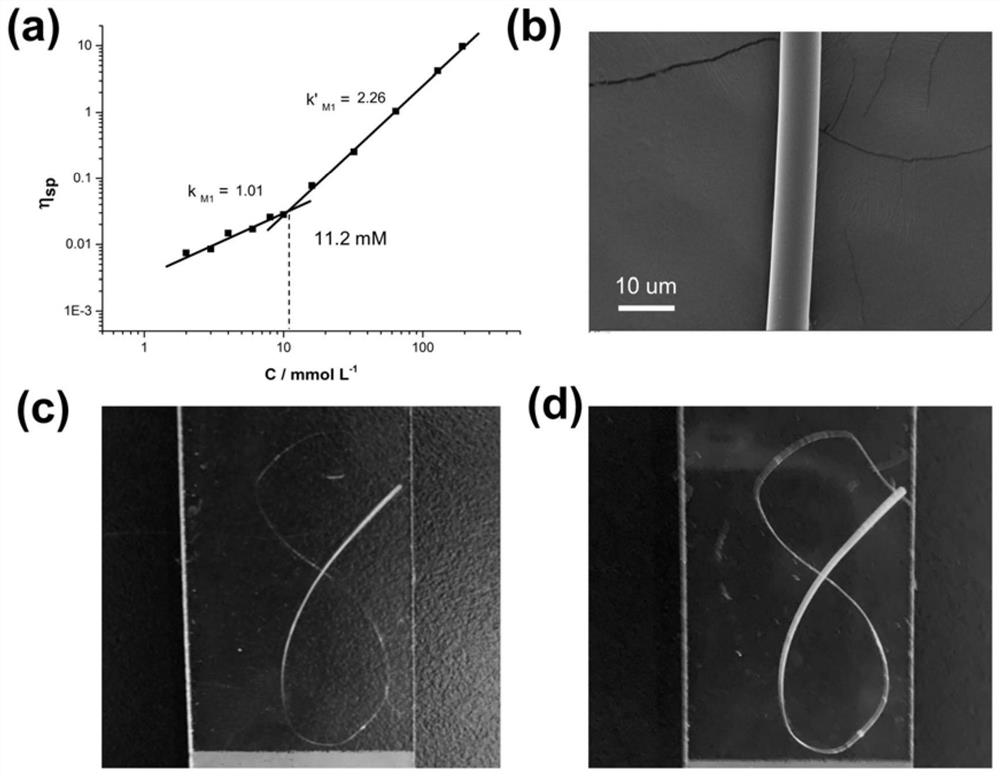

[0099] The synthesis of Compound H and Compound G is the same as in Example 1. Preparation of supramolecular polymers: The host compound H and the secondary ammonium salt guest G were mixed at a molar ratio of 1:1 equivalent, dissolved in a solvent with a volume ratio of 1:1 of chloroform:acetonitrile, ultrasonicated for 10 minutes, and left to stand for 24 hours. When the concentrations of compounds H and G are controlled at 50mmol / L and 600mmol / L, it is verified that the supramolecular polymer materials prepared with higher concentrations have better luminescent effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com