Preparation method of three-dynamic cross-linked self-repairing polyurethane and product thereof

A dynamic cross-linking and self-healing technology, applied in the field of polymer materials, can solve the problems of low repair efficiency, low reversible non-covalent bond energy, poor mechanical properties, etc., and achieve the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

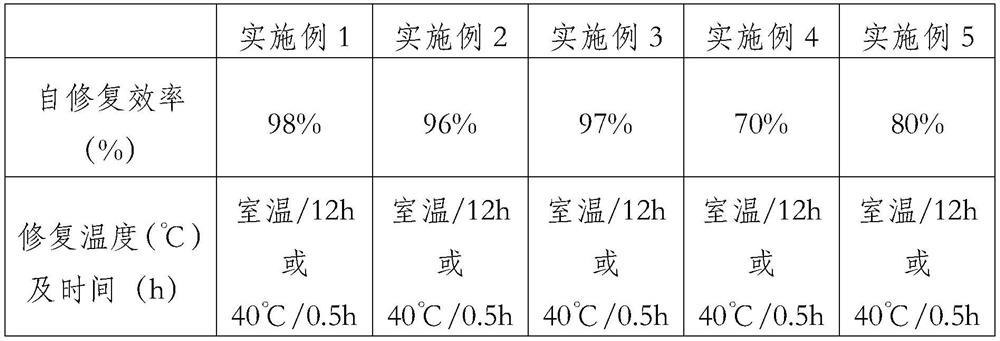

Embodiment 1

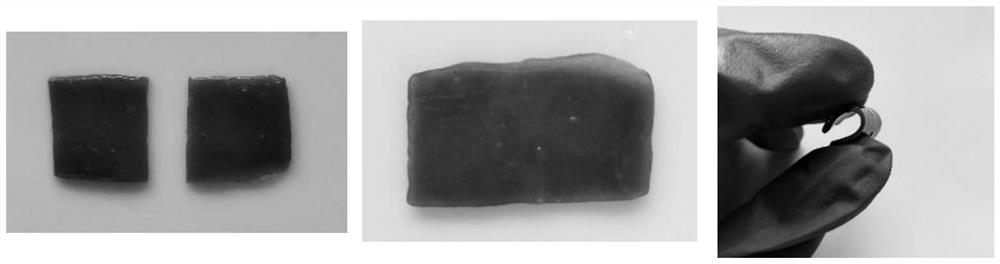

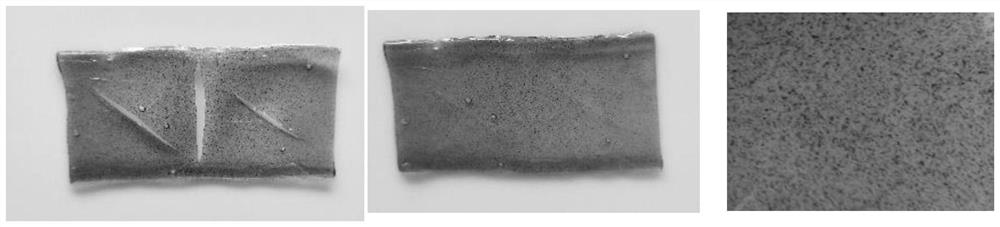

[0030] This embodiment provides a preparation method of three dynamically cross-linked self-healing polyurethanes, including:

[0031] (1) Add 3mmol isophorone diisocyanate, 1.5mmol polycarbonate diol 1000, 0.5mmol polytetrahydrofuran diol 2000, 1mmol 2,6-diaminopyridine and 10mL tetrahydrofuran solvent into a device equipped with mechanical stirring and condensing reflux In a three-necked flask, the oil bath was heated to 70°C to react for 6h; then 0.5mmol 1,3-propane sultone was added dropwise to the reaction system, and reacted at 70°C for 3h.

[0032] (2) 0.5mmol ZnCl 2 Add to the above reaction system, react at room temperature for 12 hours, pour into a polytetrafluoroethylene mold, dry at room temperature for 1 day, and then vacuum dry at 40° C. for 1 day to obtain the three-dynamically cross-linked self-healing polyurethane.

Embodiment 2

[0034] This embodiment provides a preparation method of three dynamically cross-linked self-healing polyurethanes, including:

[0035] (1) Add 3mmol of hexamethylene diisocyanate, 1mmol of polycarbonate diol 1000, 1mmol of polytetrahydrofuran diol 1000, 1mmol of 3,5-diaminopyridine and 10mL of tetrahydrofuran solvent into three ports equipped with mechanical stirring and condensing reflux device In the flask, the temperature of the oil bath was raised to 80° C. for 4 h; then 0.25 mmol γ-butyrolactone was added dropwise to the reaction system, and the reaction was carried out at 80° C. for 2 h.

[0036] (2) 0.75mmol Zn(CF 3 SO 3 ) 2 Add it to the above reaction system, react at room temperature for 12 hours, pour into a polytetrafluoroethylene mold, dry at room temperature for 2 days, and then vacuum dry at 40° C. for 2 days to obtain the three-dynamically cross-linked self-healing polyurethane.

Embodiment 3

[0038] This embodiment provides a preparation method of three dynamically cross-linked self-healing polyurethanes, including:

[0039] (1) Add 3mmol dicyclohexylmethane diisocyanate, 0.5mmol polycarbonate diol 2000, 0.5mmol polytetrahydrofuran diol 2000, 2mmol 2,6-diaminopyridine and 10mL tetrahydrofuran solvent into a device equipped with mechanical stirring and condensing reflux In a three-necked flask, the oil bath was heated to 90°C for 3 hours; then 1.5 mmol γ-butyrolactone was added dropwise to the reaction system, and reacted at 90°C for 1 hour.

[0040] (2) 0.5mmol FeCl 3 Added to the above reaction system, reacted at room temperature for 12 hours, poured into a polytetrafluoroethylene mold, dried at room temperature for 3 days, and then dried in vacuum at 40° C. for 3 days to obtain the triple dynamic cross-linked self-healing polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com