High-temperature-resistant asphalt composite waterproof coiled material and preparation method thereof

A waterproof membrane and high temperature resistant technology, which is applied in the direction of asphalt material adhesives, building insulation materials, polymer adhesive additives, etc., can solve the problems of reduced service life, poor high temperature resistance, and self-performance decline, and achieve The effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

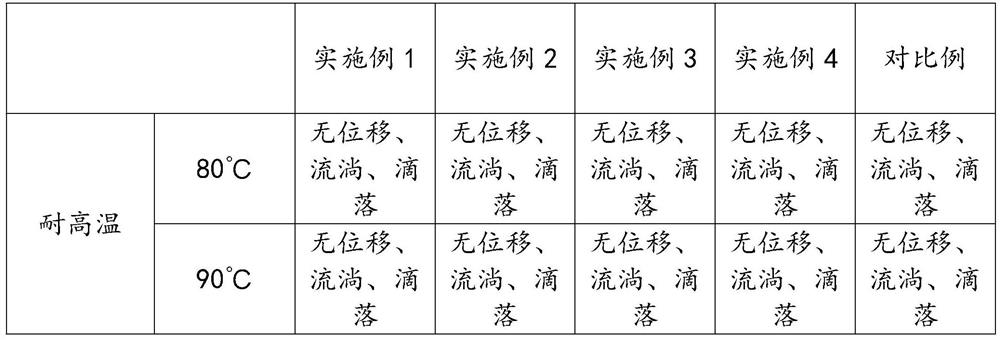

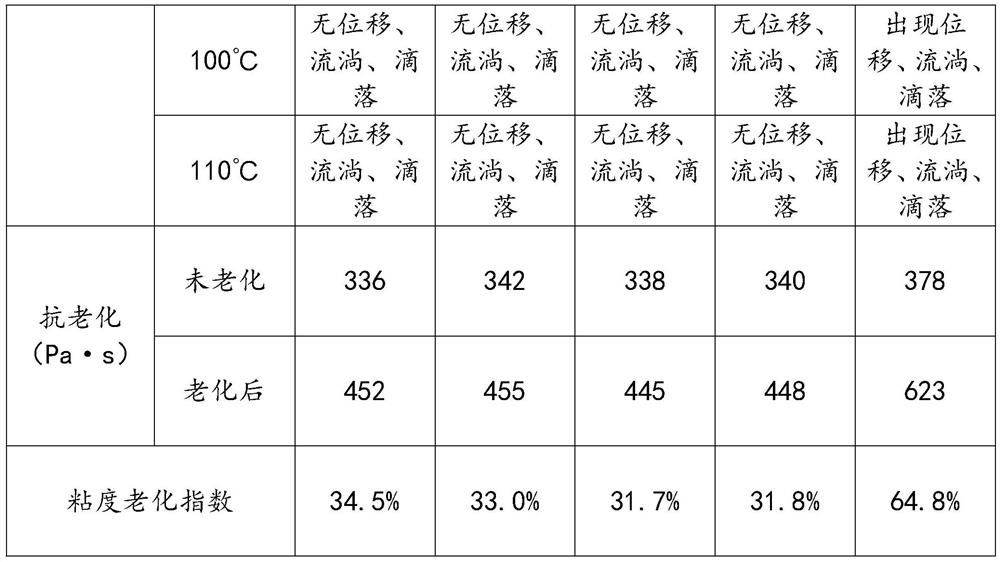

Examples

Embodiment 1

[0033] A high-temperature-resistant asphalt composite waterproof membrane, made of the following raw materials in parts by weight: 70#40 parts of base asphalt, 400610 parts of naphthenic oil, 10 parts of heat-resistant rubber, and 20 parts of anti-aging filler;

[0034] Step S1: Add base asphalt 70# into the reaction kettle, heat at 210°C until base asphalt 70# is completely melted, add naphthenic oil 4006 until the penetration of asphalt is 200, and prepare asphalt Oil;

[0035] Step S2: crush the heat-resistant rubber through a 50-mesh sieve to obtain rubber powder, add the rubber powder and asphalt oil into the stirring tank, stir and add the rubber powder at 500r / min at a temperature of 215°C and anti-aging fillers until uniformly mixed to obtain a mixture;

[0036] Step S3: Add the mixture prepared in Step S2 to a high-speed shearing machine, and then shear for 30 minutes at a speed of 4000r / min and a temperature of 215°C, and then continue stirring at a speed of 500r / mi...

Embodiment 2

[0048] A high-temperature-resistant asphalt composite waterproof membrane, made of the following raw materials in parts by weight: 70#43 parts of base asphalt, 400611 parts of naphthenic oil, 12 parts of heat-resistant rubber, and 23 parts of anti-aging filler;

[0049] Step S1: Add base asphalt 70# into the reaction kettle, heat at 220°C until base asphalt 70# is completely melted, add naphthenic oil 4006 until the penetration of asphalt is 200, and prepare asphalt Oil;

[0050] Step S2: crush the heat-resistant rubber through a 50-mesh sieve to obtain rubber powder, add the rubber powder and asphalt oil into the stirring tank, stir and add the rubber powder at 500r / min at a temperature of 220°C and anti-aging fillers until uniformly mixed to obtain a mixture;

[0051] Step S3: Add the mixture prepared in step S2 to a high-speed shearing machine, and then shear for 35 minutes at a speed of 4200r / min and a temperature of 220°C, and then continue stirring at a speed of 500r / mi...

Embodiment 3

[0053] A high-temperature-resistant asphalt composite waterproof membrane, made of the following raw materials in parts by weight: 70#48 parts of base asphalt, 400612 parts of naphthenic oil, 13 parts of heat-resistant rubber, and 28 parts of anti-aging filler;

[0054] Step S1: Add base asphalt 70# into the reaction kettle, heat at 230°C until base asphalt 70# is completely melted, add naphthenic oil 4006, until the penetration of asphalt is 210, and prepare asphalt Oil;

[0055] Step S2: Grinding the heat-resistant rubber through a 80-mesh sieve to obtain rubber powder, adding the rubber powder and asphalt oil into the stirring tank, stirring at 800r / min and 225°C and adding the rubber powder and anti-aging fillers until uniformly mixed to obtain a mixture;

[0056] Step S3: Put the mixture prepared in step S2 into a high-speed shearing machine, and then shear for 35 minutes at a speed of 4800r / min and a temperature of 225°C, and then continue stirring at a speed of 800r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com