Hydrated salt phase separation inhibition system

A hydrated salt and phase separation technology, applied in the field of phase change energy storage, can solve the problems of loss of phase separation inhibition, failure of heat storage device, reduction of heat storage and release rate, etc., to protect from contact with air and prolong service life , the effect of jet disturbance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

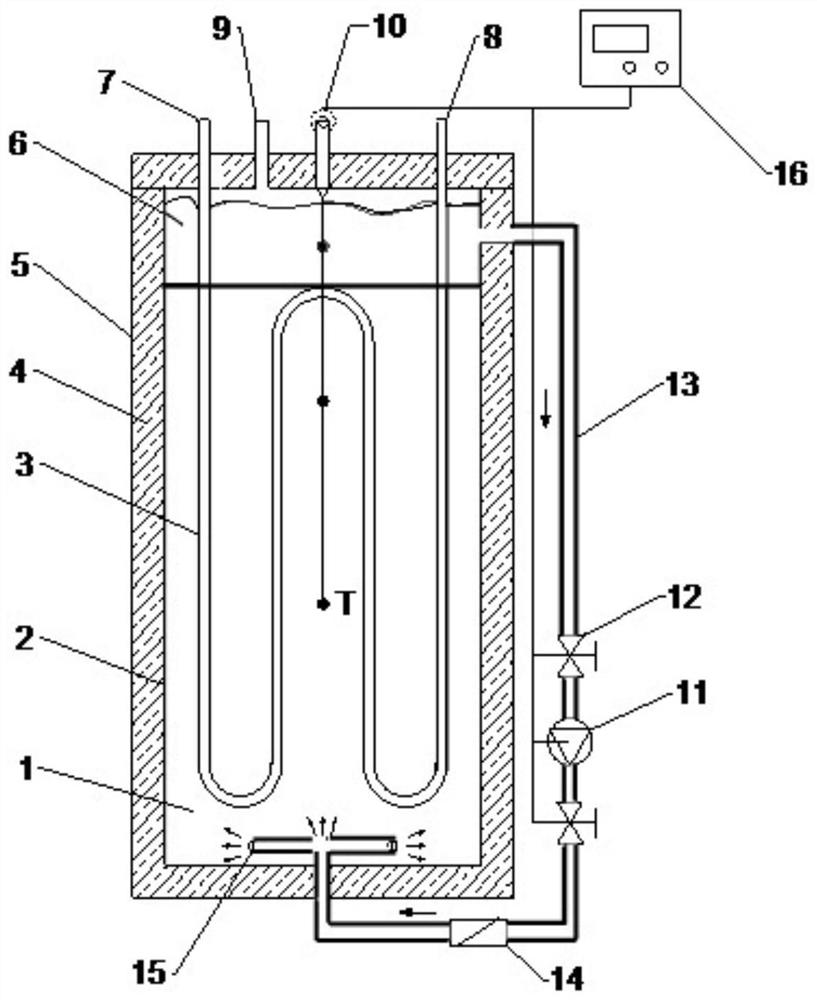

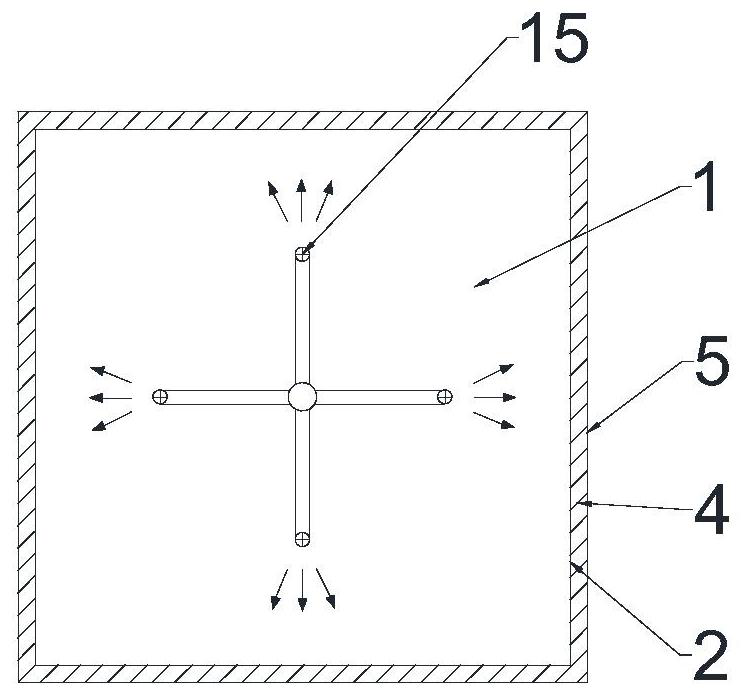

[0038] Sodium Sulfate Decahydrate (Na 2 SO 4 10H 2 O) is a typical hydrated salt phase change material 1 with a phase transition temperature of 32°C, which is very suitable for use in products such as floor heating and cool pads. However, Na 2 SO 4 10H 2 O has obvious phase separation phenomenon in applied engineering. Therefore, this implementation case uses Na 2 SO 4 10H 2 O is used as the hydrated salt phase-change material 1, and liquid paraffin (C18) is used as the liquid medium 6, and the following examples are described.

[0039] First, according to the device structure design drawing of the invention, the device system is made. After the system is completed, the Na 2 SO 4 10H 2 O is filled in the inner tank 2 of the heat storage device in the form of solid powder. Na 2 SO 4 10H 2 After the filling is completed, the heat storage process is started by the control system 16, so that the heating medium (the temperature of the heating medium is 45° C.) enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com