Efficient ternary organic solar cell prepared based on step-by-step deposition method

A technology of organic solar cells and deposition method, applied in the field of solar cells, can solve problems such as inhomogeneity of thin films, time-consuming, and complicated process operations, and achieve the effects of charge recombination inhibition, crystallinity improvement, and energy level structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

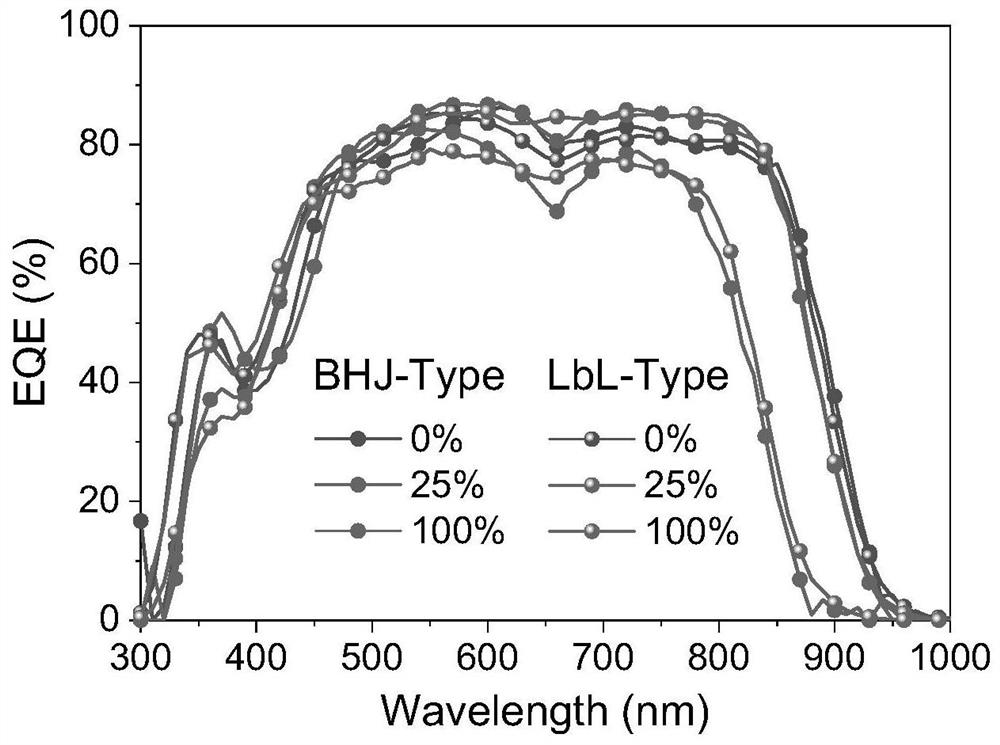

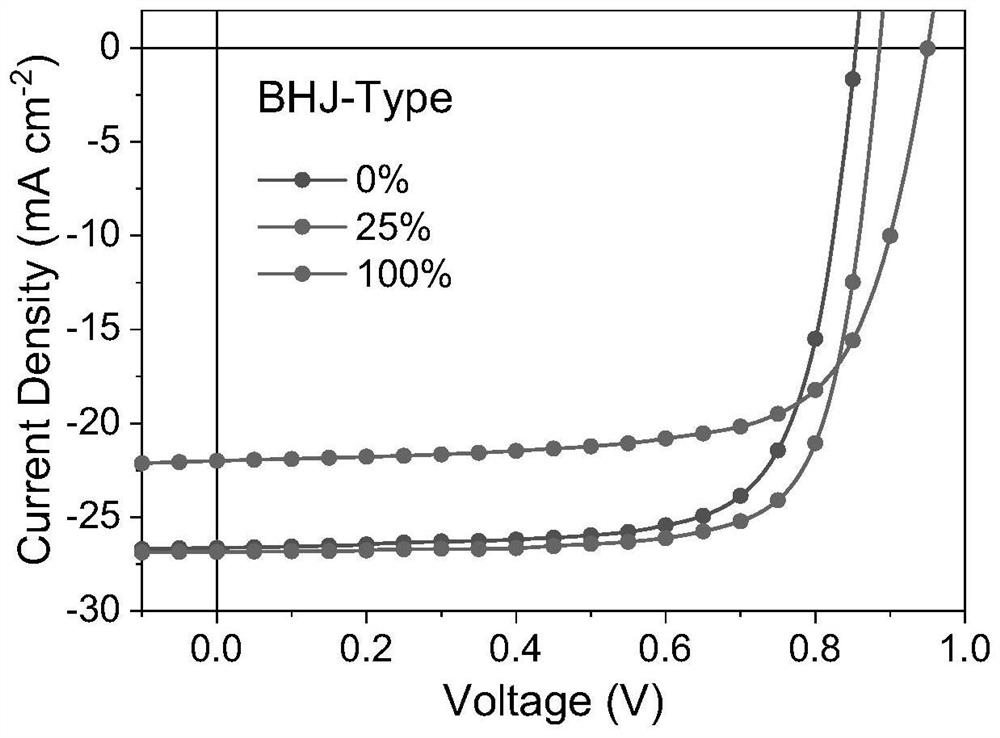

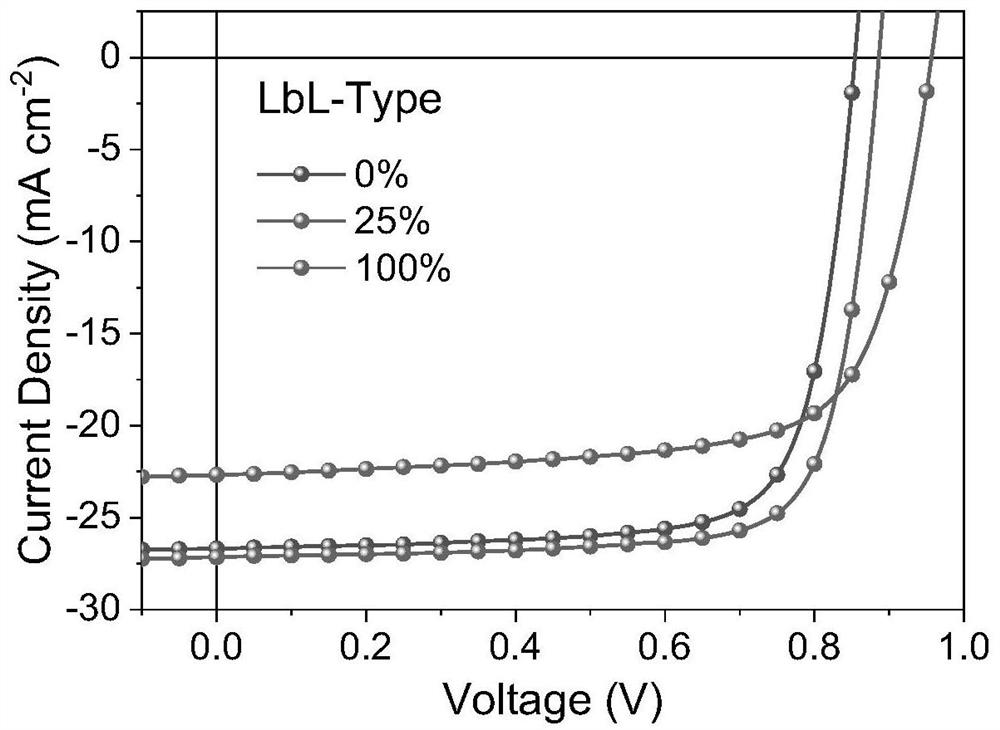

Embodiment 1

[0018] The transparent conductive glass with strip-shaped ITO (anode) etched on the surface is cleaned with cleaning agent, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with ultraviolet ozone for 15 minutes; Spin-coat a layer of PEDOT:PSS with a thickness of 20 nm on the surface at a rotation speed of 4500 rpm, and then anneal at 170° C. for 20 minutes, and then transfer the sheet to a glove box. Preparation of BHJ-type organic solar cells: PM6:BO-4Cl (weight ratio 1:1.2) was added with 1,8-diiodooctane (DIO) with a volume ratio of 0.25% and a total concentration of 17.6mg / mL The mixed solution in chloroform was spin-coated at a speed of 3500 rpm for 30 seconds to obtain an active layer with a thickness of 115 nm. The active layer is annealed at 100° C. for 10 minutes. Then on the active layer, a 5 nm thick PFN-Br modification layer was spin-coated with 0.5 mg / mL PFN-Br methanol solution. Finally, a layer of Ag electrode (cathod...

Embodiment 2

[0023] The transparent conductive glass with strip-shaped ITO (anode) etched on the surface is cleaned with cleaning agent, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with ultraviolet ozone for 15 minutes; Spin-coat a layer of PEDOT:PSS with a thickness of 20 nm on the surface at a rotation speed of 4500 rpm, and then anneal at 170° C. for 20 minutes, and then transfer the sheet to a glove box. Preparation of BHJ type organic solar cells: PM6:BO-4Cl:BTP-S2 (wherein the donor , the total weight ratio of the acceptor is 1:1.2, and the mass ratio of BTP-S2 in the acceptor is 15%) in chloroform, spin coating for 30 seconds at a speed of 3500 rpm to obtain an active layer with a thickness of 115 nm. The active layer is annealed at 100° C. for 10 minutes. Then on the active layer, a 5 nm thick PFN-Br modification layer was spin-coated with 0.5 mg / mL PFN-Br methanol solution. Finally, a Ag electrode (cathode) with a thickness of 100n...

Embodiment 3

[0026] The transparent conductive glass with strip-shaped ITO (anode) etched on the surface is cleaned with cleaning agent, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with ultraviolet ozone for 15 minutes; Spin-coat a layer of PEDOT:PSS with a thickness of 20 nm on the surface at a rotation speed of 4500 rpm, and then anneal at 170° C. for 20 minutes, and then transfer the sheet to a glove box. Preparation of BHJ type organic solar cells: PM6:BO-4Cl:BTP-S2 (where donor, acceptor The total weight ratio is 1:1.2, and the mass ratio of BTP-S2 in the acceptor is 25%) in chloroform, and the mixed solution is spin-coated at a speed of 3500 rpm for 30 seconds to obtain an active layer with a thickness of 115 nm. The active layer is annealed at 100° C. for 10 minutes. Then on the active layer, a 5 nm thick PFN-Br modification layer was spin-coated with 0.5 mg / mL PFN-Br methanol solution. Finally, a layer of Ag electrode (cathode) with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com