Refined vanadium ultra-low emission production method

A production method and ultra-low technology, applied in the field of vanadium product processing, can solve problems such as continuous feeding and discharging of materials in the sintering process, waste gas treatment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

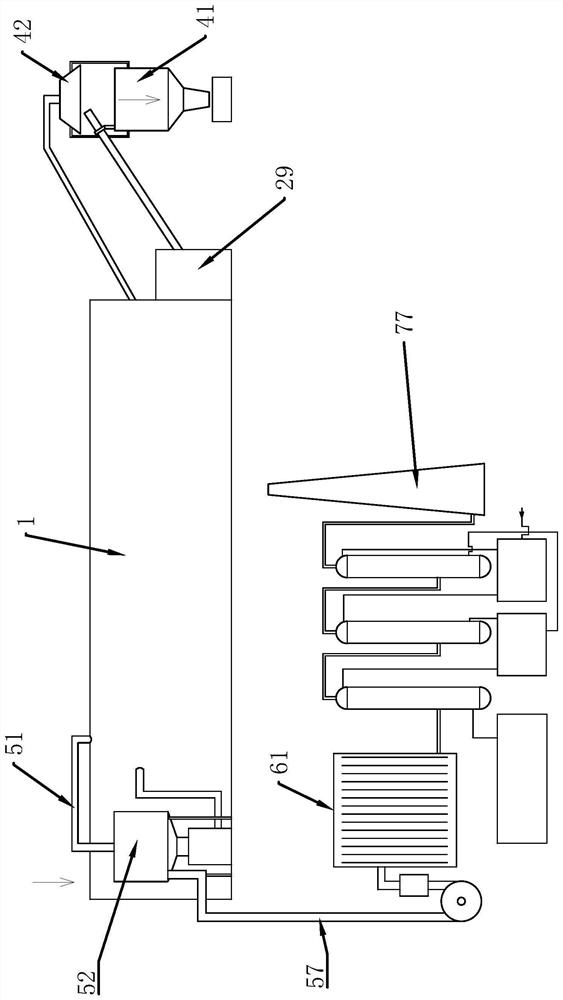

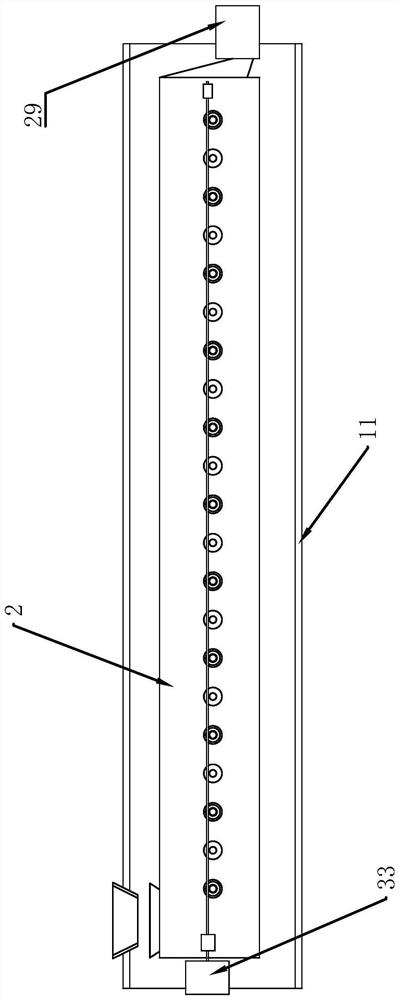

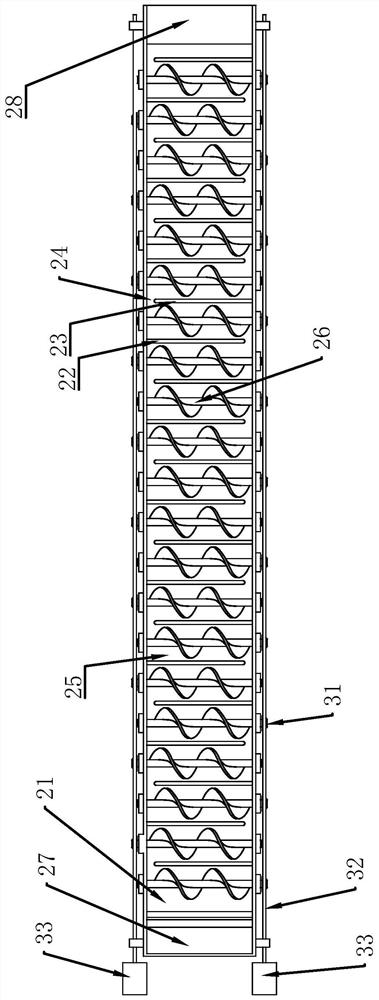

[0037] The ultra-low emission production method of refined vanadium includes the following steps: figure 1 As shown, the ammonium metavanadate filter cake is crushed into powder or small particle size particles, and continuously sintered in a sintering kiln 1 at 100-125 °C;

[0038] The exhaust gas discharged from the sintering kiln 1 is subjected to bag dust removal under the premise of heat preservation, and the filter residue of the bag dust removal returns to the sintering kiln 1;

[0039] The exhaust gas after bag dust removal enters a cooling room 61 for secondary cooling after being cooled once;

[0040] After two times of cooling, the waste gas is sprayed three times to complete the separation of ammonia in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com