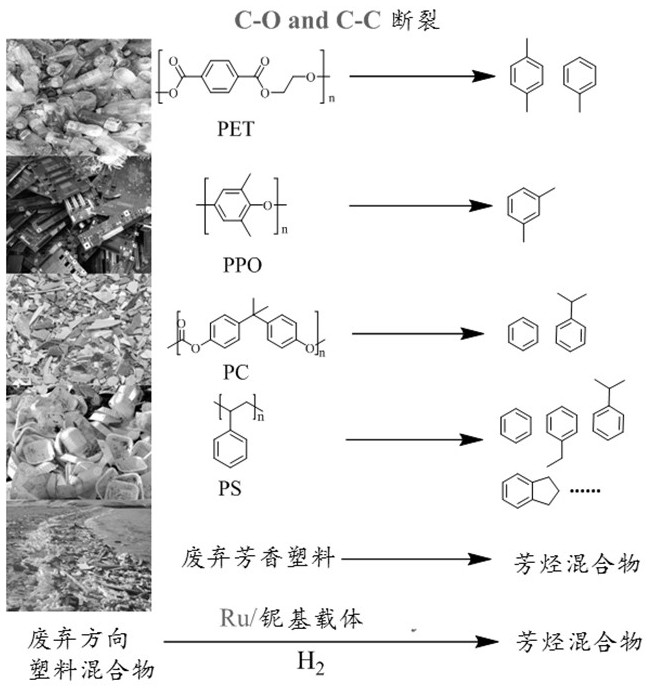

Method for preparing aromatic hydrocarbon by hydrocracking aromatic ring-containing polymer

A hydrocracking and aromatic ring technology, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, hydrocarbon cracking to produce hydrocarbons, and hydrocarbons, etc., can solve the problems of complex products and low yields, and achieve high added value and good industrial effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

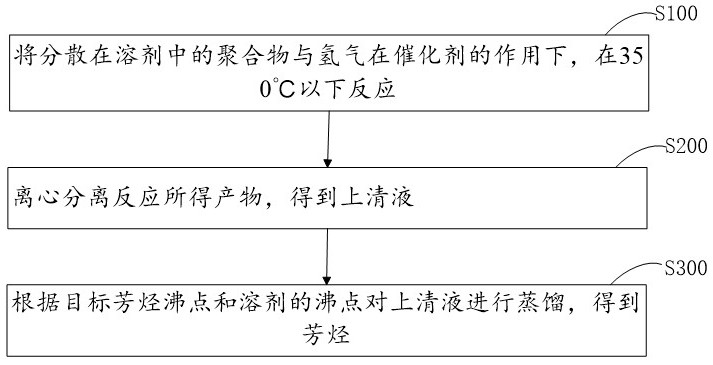

Method used

Image

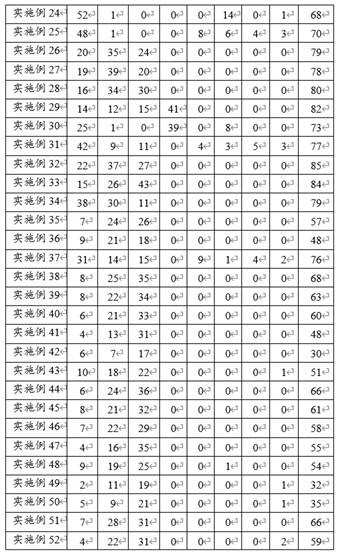

Examples

Embodiment 1

[0086] Test material: polymer containing aromatic ring: polyethylene terephthalate, polymer mass containing aromatic ring: 0.1g; solvent: water, solvent mass: 10g; substrate concentration: 1%;

[0087] Catalyst: the active component is Ru, the carrier is Nb 2 o 5 , catalyst quality 0.1g;

[0088] Test conditions: hydrogen pressure: 0.3MPa; reaction temperature: 200°C; reaction time: 10h;

[0089] Test method: crush 0.1g polyethylene terephthalate to 10mm in a pulverizer, and disperse the crushed polyethylene terephthalate in 10g water, then separate the dispersion and 0.1g Ru / Nb 2 o 5 Put it into a stainless steel high-pressure reactor with a polytetrafluoroethylene liner, seal it, fill it with 0.3MPa hydrogen, heat up to the required temperature of 200°C under rapid stirring, stop after 10 hours of reaction, cool, and centrifuge the catalyst, and take the supernatant The liquid is distilled sequentially from low to high boiling points to obtain toluene and 62% p-xylene ...

Embodiment 2

[0091] The only difference from Example 1 is that the active component in the catalyst is Fe.

Embodiment 3

[0093] The only difference from Example 1 is that the active component in the catalyst is Co.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com