Method for extracting alpha-starch from cyperus esculentus

An extraction method, the technology of oily bean, which is applied in the field of extraction of α-starch in oily bean by means of puffing technology, can solve the problems of low starch rate, unstable starch properties, easy introduction of impurities, etc., and achieve simple starch refining , No reagent residue, increase the effect of contact chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

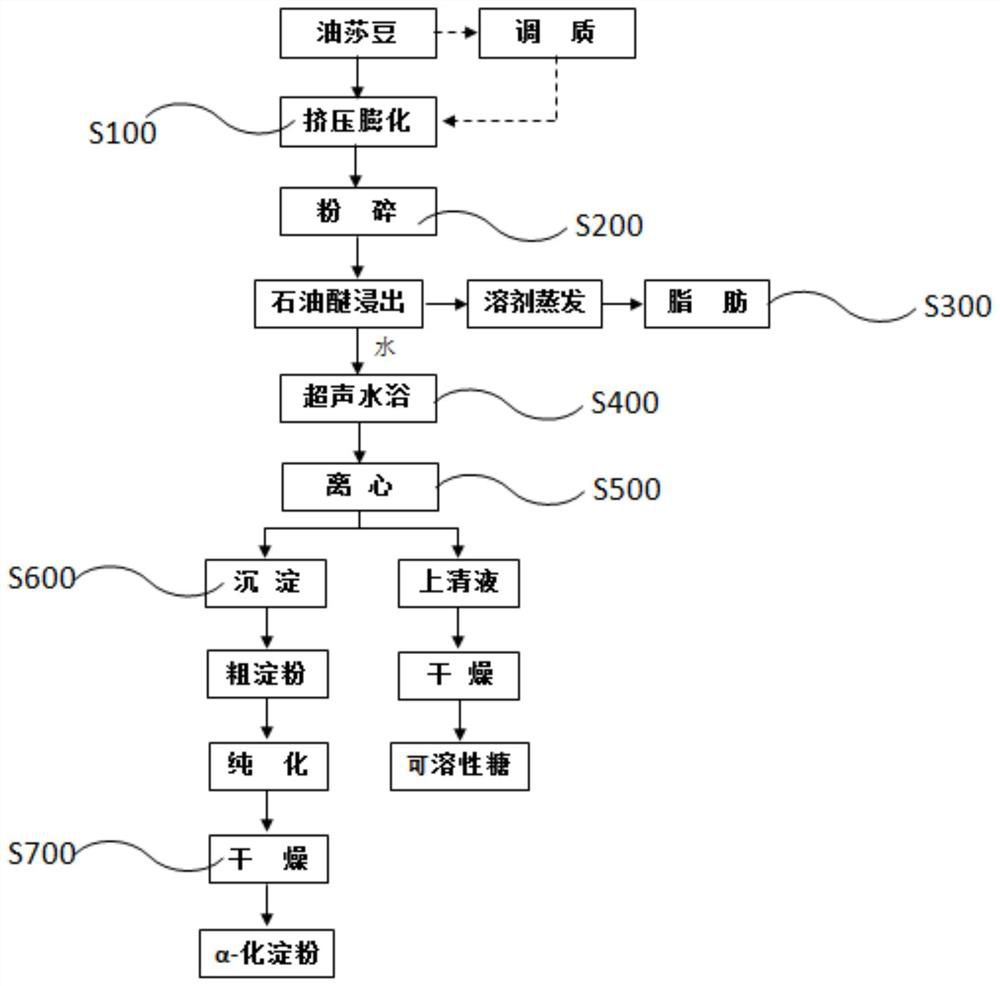

[0032] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0033] see figure 1 , figure 1 It is a method flow chart of an embodiment of the present invention, and the method for extracting α-starch in the oil-sand bean of the present invention comprises the following steps:

[0034] Step S100, extrusion and puffing pretreatment, extrusion and puffing treatment is carried out according to the characteristics of different oily bean raw materials, the process conditions of the extrusion and puffing pretreatment are preferably: the moisture content of the raw material of the oily bean is 8% to 12% , the puffing temperature of the extruder is 120-140°C, the screw speed of the extruder is 120-140r / min, and the die hole diameter of the extruder is 8-12mm;

[0035] Step S200, crushing the extruded and puffed oily bean raw material with a wall breaker or a pulverizer, and passing the crushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com