Halogen-free flame retardant pressure sensitive adhesive composition and adhesive tape

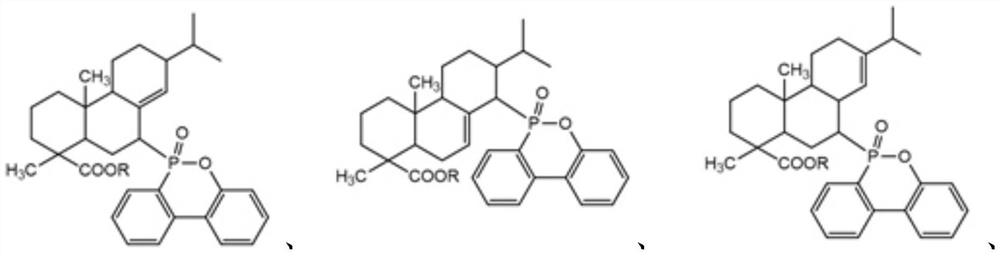

A pressure-sensitive adhesive, flame retardant technology, applied in the direction of adhesive types, ester copolymer adhesives, conjugated diene adhesives, etc., can solve the problems of reducing the cohesion and adhesion of tapes, Achieve excellent flame retardancy, overcome process problems, and overcome the effects of flame retardant migration and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] In the embodiments of the present invention, the following test methods are used to test the peeling force, holding force and flame retardancy.

[0079] 1. Test method

[0080] (1) Peel adhesion test

[0081] The test was carried out on the 180° peel force of steel - open side and lined side (measurement method V1).

[0082] The peel adhesion to steel is measured under the test conditions of a temperature of 23°C±1°C and a relative humidity of 50%±5%. Samples were cut to a width of 20mm and adhered to a steel plate. The plates are cleaned and conditioned prior to measurement. For this purpose, the plate was first wiped with acetone and then left in air for 5 minutes to allow the solvent to evaporate.

[0083] Then, the side of the three-layer assembly facing away from the test substrate is lined with 25 μm or other thickness of PET, PVC and other plastic films to prevent the stretching or deformation of the adhesive layer during the test. The test specimens were t...

preparation example 1

[0098] Preparation Example 1: Preparation of Polyacrylate I (PA-I)

[0099] A 30 L reactor conventionally used for radical polymerization was charged with 200 g of acrylic acid, 3000 g of butyl acrylate (BA), 6.8 kg of 2-ethylhexyl acrylate (EHA) and 7.24 kg of petroleum ether / acetone (70: 30). After nitrogen had been passed through the reactor for 45 minutes under stirring, the reactor was heated to 58°C and 5.0 g of 2,2'-azobis(2-methylbutyronitrile) ( 67, purchased from DuPont). The jacket temperature was then raised to 75° C. and the reaction was carried out constantly at this external temperature. After one hour of reaction time, an additional 5.0 g of 67. Dilution was performed after 3 hours with 2.0 kg of petroleum ether / acetone (70:30) and after 6 hours with 1.0 kg of petroleum ether / acetone (70:30). In order to reduce residual monomers, a 15 g portion of bis(4-tert-butylcyclohexyl)peroxydicarbonate ( 16, purchased from Akzo Nobel), and added 15g portion of ...

preparation example 2

[0100] Preparation Example 2: Preparation of Polyacrylate II (PA-II)

[0101] A conventional 20 L glass reactor with evaporative cooling suitable for free radical polymerization was charged with 3000 g of a monomer mixture comprising 2190 g of ethylhexyl acrylate, 600 g of methyl acrylate and 210 g of acrylic acid, and 2000 g of acetone: special Boiling point (SBP) petroleum ether 60 / 95 (1:1). After nitrogen had been passed through the reactor for 45 minutes with stirring, the reactor was heated to 58°C and 1.5 g of 2,2'-azobis(2-methylbutyronitrile) dissolved in 60 g of acetone was added ( 67, purchased from DuPont). Afterwards, the external heating bath was heated to 75° C. and the reaction was carried out constantly at this external temperature. After one hour of reaction time, an additional 1.5 g of 67. After 3 hours, the batch was diluted with 900 g of SBP petroleum ether 60 / 95.

[0102] After a reaction time of 5.5 hours, 4.5 g of bis(4-tert-butylcyclohexyl)peroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com