Method for preparing thin high-strength composite heat-conducting functional film of sandwich structure

A sandwich structure, high-strength technology, applied in the direction of fiber type, physical treatment, fiber treatment, etc., can solve problems such as loose interface links, performance deterioration, and difficult to control the toxicity of the reduction process, and achieve low cost, good mechanical properties, and effective use Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention: a method for efficiently dispersing graphene nanosheets in water through natural nanocellulose, the method comprising the following steps:

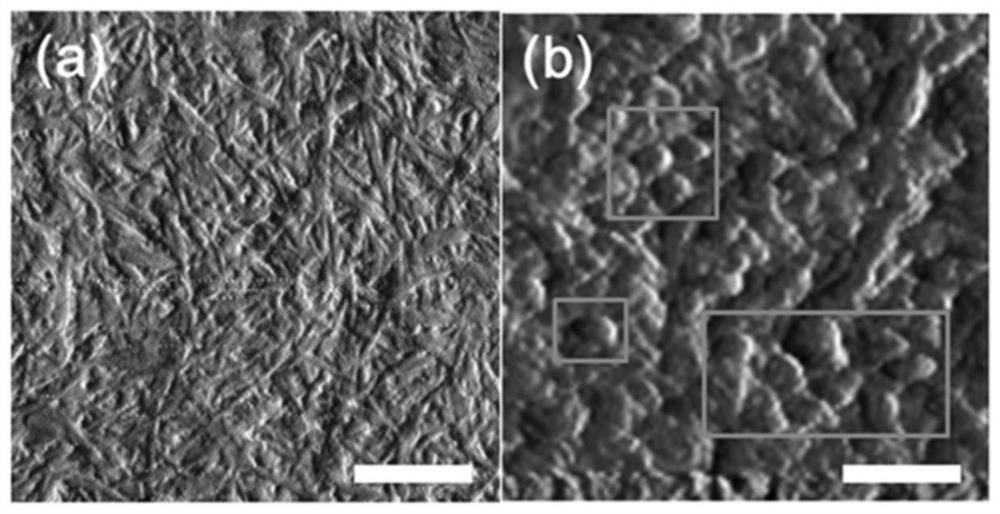

[0022] Add few-layer graphene or multi-layer graphene directly to the prepared TEMPO-mediated oxidized nanocellulose gel (it can also be a high-concentration aqueous suspension), and combine nanocellulose and graphite under the action of continuous shearing and stirring. Alkene mixed evenly to obtain a viscous dispersion.

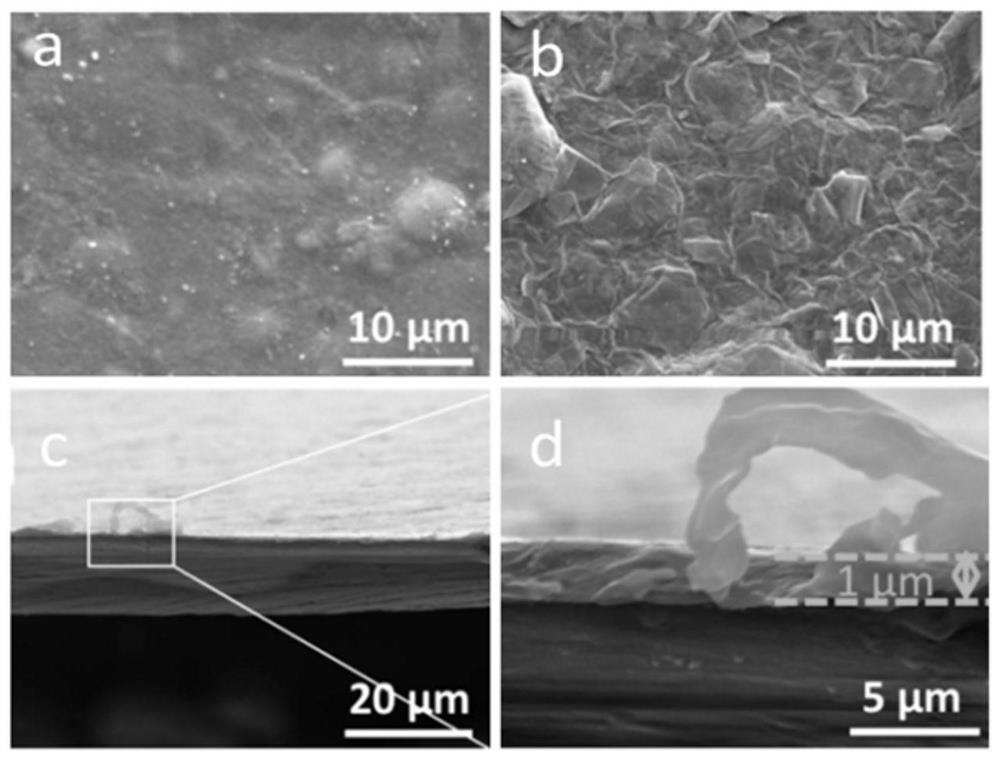

[0023] A certain volume of GO aqueous solution (approximately 20ml, 0.2mg / ml) was passed through a cellulose ester film (0.22μm pore size) with a filter device to deposit a skin layer. After the water is basically removed and there is no liquid layer in the suction cup, continue to filter the CNF aqueous suspension. After the water is basically removed and there is no liquid layer in the suction cup, add the same volume of GO suspension.

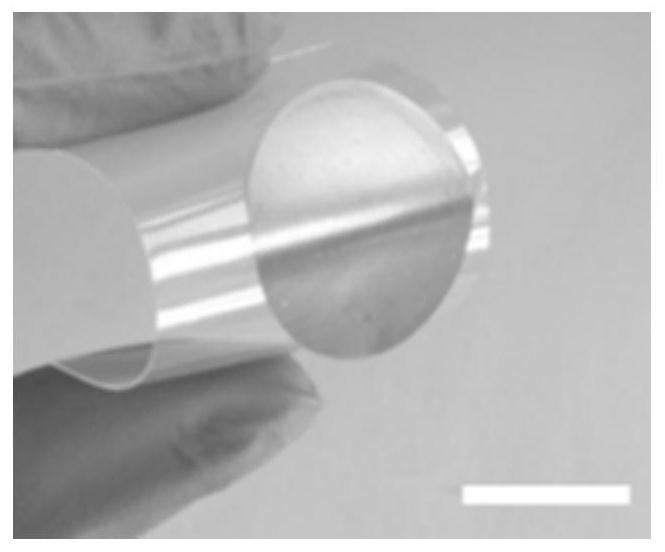

[0024] After the composite membra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap