Preparation method of electrode material for aqueous zinc ion hybrid energy storage device

A technology of hybrid energy storage and electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle life, and achieve the effects of low cost, good mechanical properties, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

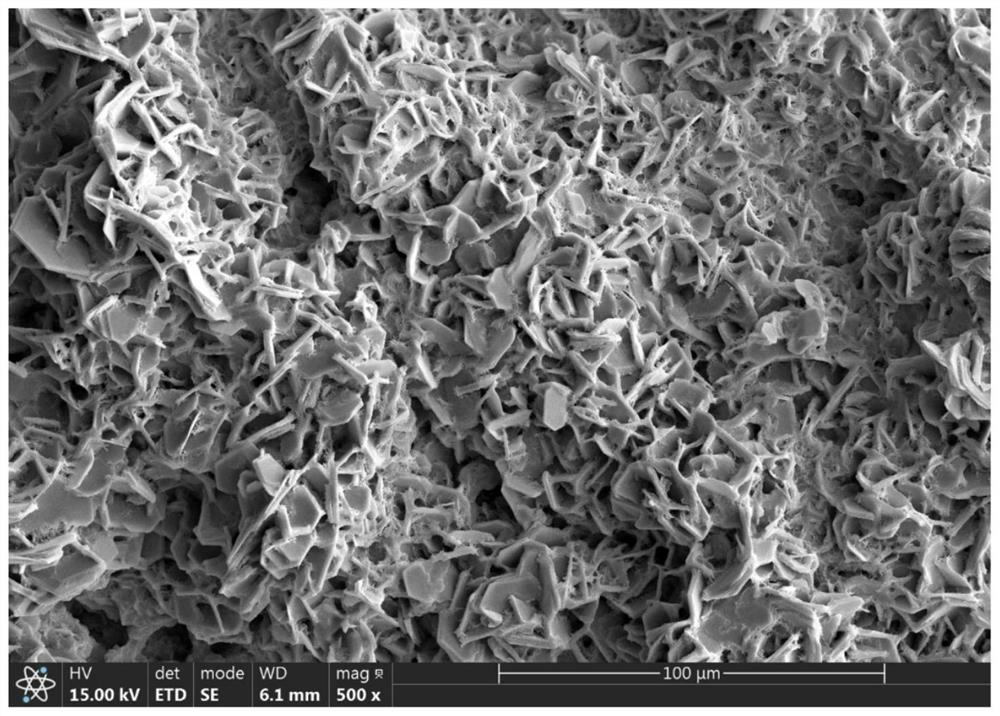

[0042] Preparation of zinc / expanded graphite anode: self-made expanded graphite as working electrode, 1M zinc sulfate and 1M sodium sulfate aqueous solution as electrolyte, Ag / AgCl reference electrode, platinum foil as counter electrode, constant current is -50mAcm -2 , and the time is kept for 1800s. After the deposition is completed, it is repeatedly cleaned with deionized water and ethanol, and then dried at 50-90°C overnight.

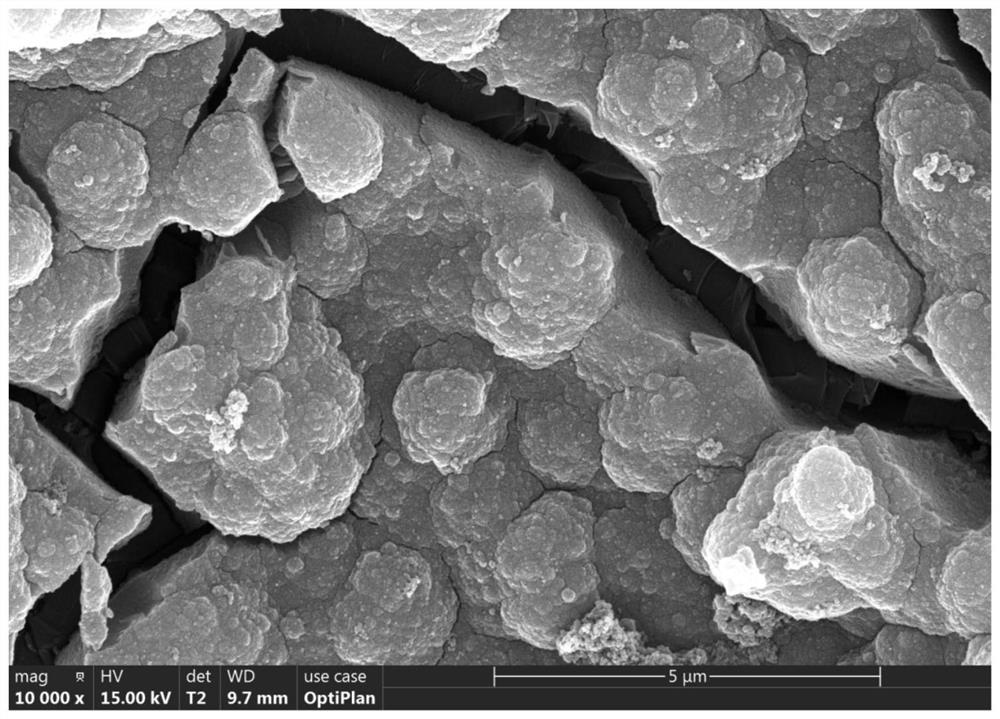

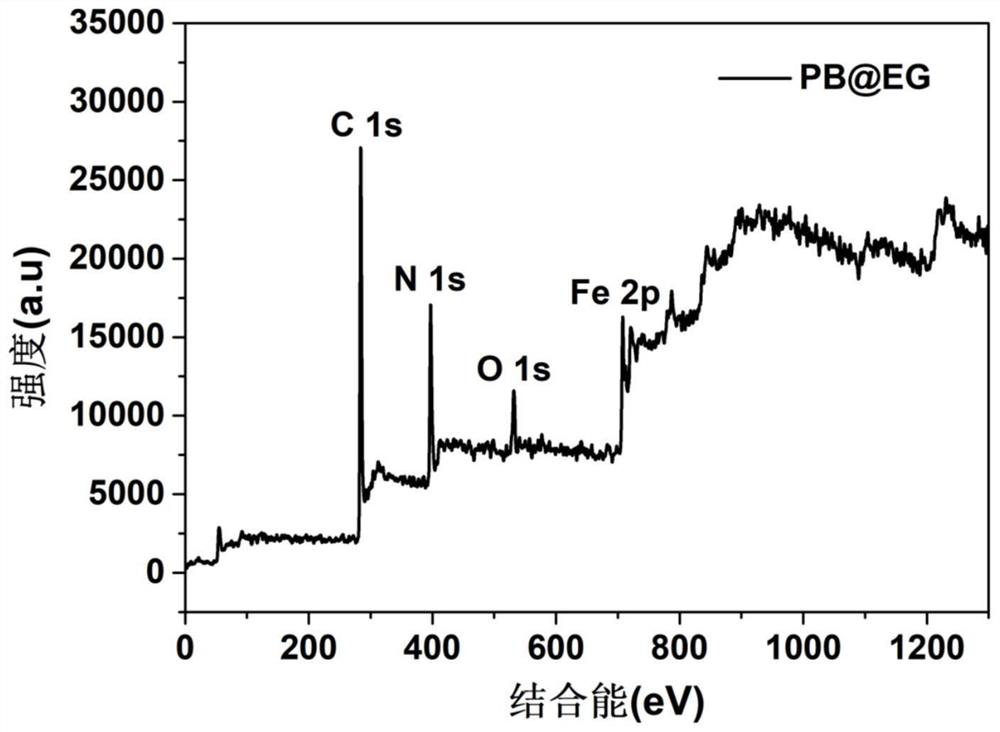

[0043] image 3 Among them, the peak of 01S corresponds to the oxygen-containing functional groups of the expanded graphite substrate, which provides more active sites; while the peaks of C1S, N 1S, and Fe 2P correspond to Prussian blue, which proves the successful polymerization of Prussian blue on expanded graphite .

[0044] Figure 4 The charge-discharge cycle graph shown in Example 5, deposition of 50 cycles brought the highest capacity contribution and cycle stability. The reason is that at 50 cycles, the thickness of the deposited Prussian...

Embodiment 1

[0046] Self-made expanded graphite is used as the working electrode, a mixed solution of 0-1M potassium ferricyanide, 0-1M ferric chloride and 80-240 μL hydrochloric acid is used as the electrolyte, Ag / AgCl is used as the reference electrode, and platinum foil is used as the counter electrode , the scan speed is 45-55mV / s, the number of turns is 10 turns, and the voltage window is (0.1-0.5)-(0.6-1)V. After the deposition, it was washed repeatedly with deionized water and ethanol, and then dried overnight at 50-90°C.

[0047] The prepared Prussian blue / expanded graphite is directly used as the cathode, the 1-3M / L zinc sulfate aqueous solution is used as the electrolyte, and the prepared zinc / expanded graphite is directly used as the anode. After assembling into an aqueous battery, the current density is 0.1mA cm -2 Under the size of , its reversible capacity is 0.1mAh cm -2 .

Embodiment 2

[0049] Self-made expanded graphite is used as the working electrode, a mixed solution of 0-1M potassium ferricyanide, 0-1M ferric chloride and 80-240 μL hydrochloric acid is used as the electrolyte, Ag / AgCl is used as the reference electrode, and platinum foil is used as the counter electrode , the scan speed is 50mV / s, the number of turns is 20 turns, and the voltage window is (0.1-0.5)-(0.6-1)V. After the deposition, it was washed repeatedly with deionized water and ethanol, and then dried overnight at 50-90°C.

[0050] The prepared Prussian blue / expanded graphite is directly used as the cathode, the 1-3M / L zinc sulfate aqueous solution is used as the electrolyte, and the prepared zinc / expanded graphite is directly used as the anode. After assembling into an aqueous battery, the current density is 0.1mA cm -2, its reversible capacity is 0.12mAh cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com