Preparation method of black phosphorus-based graphite composite lithium ion battery negative electrode material

A technology for ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of unstable electrical conductivity of materials, limiting the batch size of black phosphorus, and unstable composite structure. , to achieve the effect of improving surface defects, reducing irreversible capacity, and improving charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of black phosphorus-based graphite composite lithium ion battery negative electrode material of the present invention, comprises the following steps:

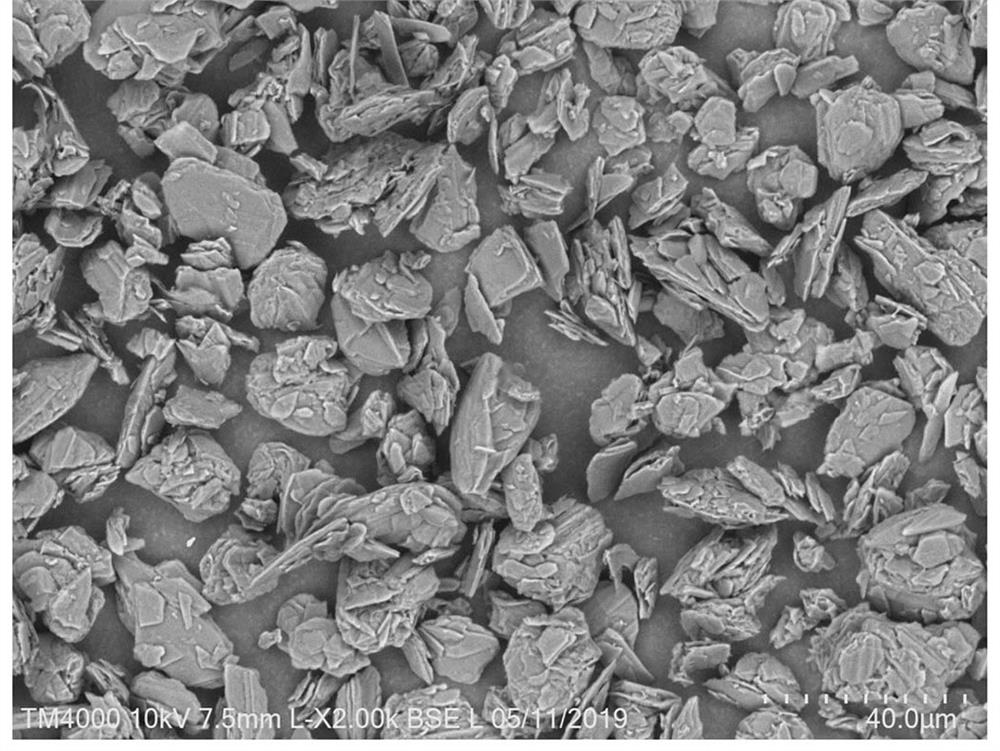

[0034] (1) Put black phosphorus with D50=15μm into a 1000mL airtight container, use N-methylpyrrolidone as solvent, then put it into a cell pulverizer for ultrasonic peeling, the ultrasonic frequency is 20KHz, and the ultrasonic time is 10h;

[0035] (2) Add graphene oxide directly to the mixture in step (1), the mass ratio of graphene oxide to black phosphorus is 5:95, and then transfer it to a hydrothermal reactor for reaction at a reaction temperature of 150°C. The time is 8h;

[0036] (3) Dry the reaction product of step (2) at 60°C, and pass nitrogen gas for protection during drying, and the flow rate of nitrogen gas is 20mL / min to obtain carbon-coated black phosphorus;

[0037] (4) Add the carbon-coated black phosphorus and artificial graphite obtained in step (3) to the solvent (N-methylpyrro...

Embodiment 2

[0041] A preparation method of black phosphorus-based graphite composite lithium ion battery negative electrode material of the present invention, comprises the following steps:

[0042] (1) Put black phosphorus with D50=15μm into a 1000mL airtight container, use N-methylpyrrolidone as solvent, and then put it into a cell pulverizer for ultrasonic peeling, the ultrasonic frequency is 21KHz, and the ultrasonic time is 12h;

[0043](2) Add graphene oxide directly to the mixture in step (1), the mass ratio of graphene oxide to black phosphorus is 5:95, and then transfer it to a hydrothermal reactor for reaction at a reaction temperature of 180°C. The time is 12h;

[0044] (3) Dry the reaction product of step (2) at 60°C, and pass nitrogen gas for protection during drying, and the flow rate of nitrogen gas is 20mL / min to obtain carbon-coated black phosphorus;

[0045] (4) Add the carbon-coated black phosphorus and artificial graphite obtained in step (3) into the solvent (N-methy...

Embodiment 3

[0048] A preparation method of black phosphorus-based graphite composite lithium ion battery negative electrode material of the present invention, comprises the following steps:

[0049] (1) Put black phosphorus with D50=15μm into a 1000mL airtight container, use N-methylpyrrolidone as solvent, then put it into a cell pulverizer for ultrasonic peeling, the ultrasonic frequency is 20KHz, and the ultrasonic time is 10h;

[0050] (2) Add graphene oxide directly to the mixture in step (1), the mass ratio of graphene oxide to black phosphorus is 5:95, and then transfer it to a hydrothermal reactor for reaction at a reaction temperature of 150°C. The time is 8h;

[0051] (3) Dry the reaction product of step (2) at 60°C, and pass nitrogen gas for protection during drying, and the flow rate of nitrogen gas is 20mL / min to obtain carbon-coated black phosphorus;

[0052] (4) Add the carbon-coated black phosphorus and artificial graphite obtained in step (3) into the solvent (N-methylpyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com