Corrosion-resistant coating on surface of sintered neodymium-iron-boron magnet and preparation method of surface corrosion-resistant coating

A technology of NdFeB and corrosion resistance, which is applied in the field of corrosion resistance coating on the surface of sintered NdFeB magnets and its preparation, can solve the problems of corrosion resistance, brittleness resistance and insulation effects, and achieve excellent bonding performance, Uniform structure distribution and improved surface corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

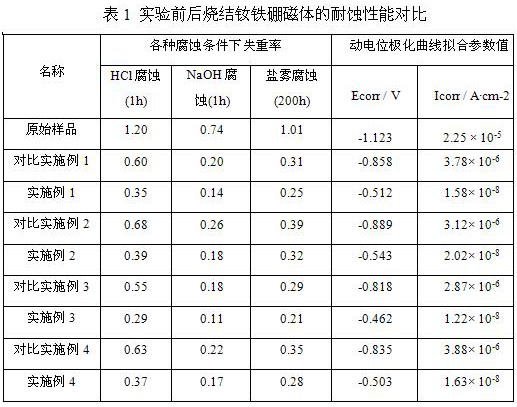

Embodiment 1

[0027] Put the sintered NdFeB magnet obtained by the surface micro-arc oxidation in Comparative Example 1 into a pulse plasma explosion treatment device, use the pulse plasma explosion treatment process to carry out surface treatment on the sintered NdFeB magnet and then dry it naturally to obtain a surface containing Sintered NdFeB magnets with dense micro-arc oxidation ceramic coating; the plasma explosion treatment device adopts pure tungsten electrodes, the power supply voltage is 5 KV, the working capacitance value is 800 μ F, and the number of pulses is 3 times; the pulse plasma explosion treatment device The mixture of propane, oxygen and compressed air is used as the explosive gas, and the ratio between propane, oxygen and compressed air is 1: 4: 3.5; pure tungsten material is used as the electrode for detonation, and the explosive gas is sprayed from the spray gun Surface treatment was carried out on the test piece, the distance between the outlet of the spray gun and ...

Embodiment 2

[0033] Put the sintered NdFeB magnet obtained by the surface micro-arc oxidation in Comparative Example 1 into a pulse plasma explosion treatment device, use the pulse plasma explosion treatment process to carry out surface treatment on the sintered NdFeB magnet and then dry it naturally to obtain a surface containing Sintered NdFeB magnets with dense micro-arc oxidation ceramic coating; the plasma explosion treatment device adopts pure tungsten electrodes, the power supply voltage is 5 KV, the working capacitance value is 800 μ F, and the number of pulses is 3 times; the pulse plasma explosion treatment device The mixture of propane, oxygen and compressed air is used as the explosive gas, and the ratio between propane, oxygen and compressed air is 1: 4: 3.5; pure tungsten material is used as the electrode for detonation, and the explosive gas is sprayed from the spray gun Surface treatment was carried out on the test piece, the distance between the outlet of the spray gun and ...

Embodiment 3

[0039] Put the sintered NdFeB magnet obtained by the surface micro-arc oxidation in Comparative Example 1 into a pulse plasma explosion treatment device, use the pulse plasma explosion treatment process to carry out surface treatment on the sintered NdFeB magnet and then dry it naturally to obtain a surface containing Sintered NdFeB magnets with dense micro-arc oxidation ceramic coating; the plasma explosion treatment device uses pure tungsten electrodes, the power supply voltage is 5 KV, the working capacitance value is 1000 μF, and the number of pulses is 2 times; the pulse plasma explosion treatment device The mixture of propane, oxygen and compressed air is used as the explosive gas, and the ratio between propane, oxygen and compressed air is 1: 4: 3.5; pure tungsten material is used as the electrode for detonation, and the explosive gas is sprayed from the spray gun Surface treatment was carried out on the test piece, the distance between the outlet of the spray gun and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com