Polymer fiber product with rejection barrier structure and preparation method of polymer fiber product

A polymer fiber and polymer technology, applied in the direction of fiber treatment, fiber type, fiber chemical characteristics, etc., can solve the problems of inability to reflect the repelling effect, the barrier effect is reduced, and the structure is easy to fall off, and achieve excellent water and oil repellency. , the structure is uniform, the effect of good water repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

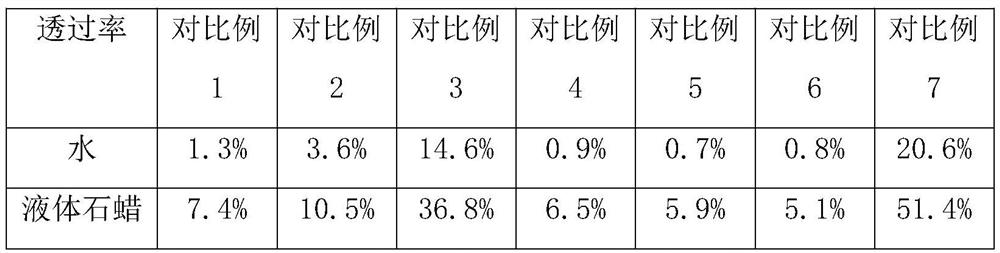

Examples

Embodiment 1

[0058] A polymer product with a repellent structure and a preparation method thereof, specifically comprising the following steps:

[0059] A. Prepare 200g of heptadecafluorodecyl methyl trimethacrylate and 9.8kg of isopropanol into a solution with a concentration of 2%, weigh 2kg of fumed silicon, slowly add the solution into the fumed silicon, and stir rapidly for 2 hours, the temperature is controlled at 50°C.

[0060] Then it was centrifuged at high speed and filtered, stirred and dried at 95° C. for 2 hours, cooled and ground to obtain the fluorine compound-coated gas-phase silicon nanometer material.

[0061] B. Treat the gas-phase silicon nanomaterials coated with fluorine compounds at 20KV high-voltage electrostatic treatment for 5 minutes

[0062] C. Add the prepared coated nanomaterials into polypropylene particles in a mass ratio of 0.5%, mix evenly, and mix and extrude through twin-screw at 210° C. to obtain mixed plastic particles.

[0063] D. Melt-spinning the ...

Embodiment 2

[0066] A polymer product with a repellent structure and its preparation method. This embodiment is a variation example of Embodiment 1. The difference from Embodiment 1 is that in step C, the mixed plastic particles are melt-blown to obtain a melt-blown non-woven fabric. The water and oil repellent product was obtained through post-processing, and the rest of the steps and conditions were the same as in Example 1.

Embodiment 3

[0068] A polymer product with a repellent structure and its preparation method. This embodiment is a modification of Embodiment 2. The difference from Embodiment 2 is that a heat treatment step is included after step D. The heat treatment step specifically includes the following steps : The melt-blown nonwoven fabric prepared in Example 2 was treated in an oven at 50° C. for 2 hours, and a water- and oil-repellent product was obtained through post-processing. The remaining steps and conditions were the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com