Negative pole piece, preparation method thereof and lithium ion secondary battery comprising negative pole piece

A technology of negative electrode sheet and negative electrode, which is applied in the field of negative electrode sheet and its preparation, can solve the problems of deteriorating battery electrolyte retention, battery cycle life decline, unfavorable electrolyte storage, etc., to improve battery rate performance and ensure ion conduction performance, improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Prepare gel particles:

[0079] With 60.0wt% binder SBR (styrene-butadiene emulsion), 20.0wt% thickener CMC-Na (sodium carboxymethyl cellulose), 20.0wt% conductive agent SP (carbon black conductive agent) and a certain amount of deionized Add water into the planetary mixing tank, stir for 8 hours at a stirring speed of 35 Hz in revolution and 1500 Hz in rotation, make it fully mixed and prepare a uniform slurry with a viscosity of 1500-8000 mPa·s. Dried the slurry under vacuum at 80°C, crushed and sieved to obtain D 50 =5μm, the specific surface area is 2m 2 / g of gel particles.

[0080] Preparation of negative electrode slurry:

[0081] 95.5wt% graphite, 1.5wt% binder SBR (styrene-butadiene emulsion), 1.5wt% thickener CMC-Na (sodium carboxymethylcellulose), 1.0wt% conductive agent SP (carbon black conductive agent), Add 0.5wt% of the above-mentioned gel particles and a certain amount of deionized water into the planetary stirring tank, stir for 8 hours at a stirrin...

Embodiment 2-11

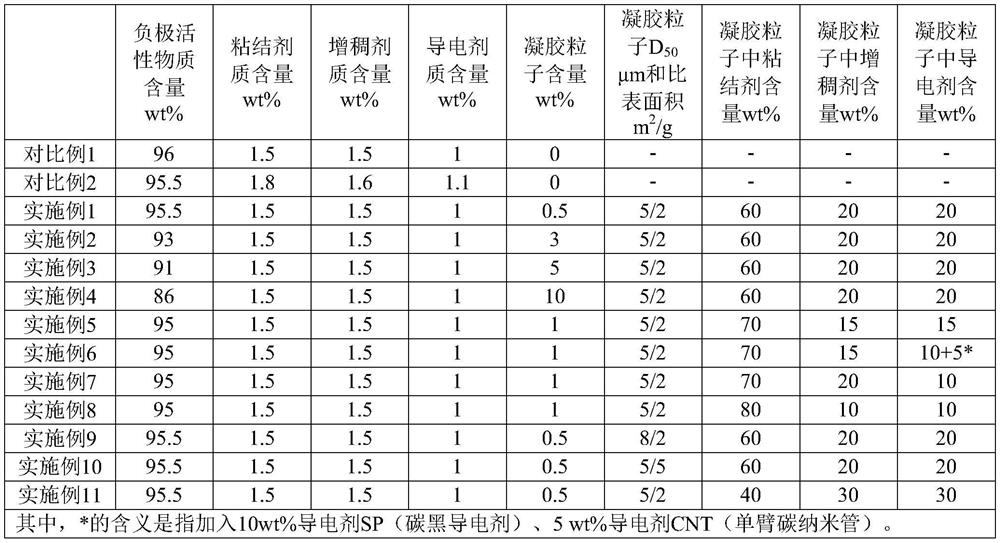

[0087] Others are the same as in Example 1, except that the addition ratio and selection of each component in the negative electrode sheet are different, as shown in Table 1.

[0088] The addition ratio and selection of each component in the negative electrode sheet of table 1 embodiment and comparative example

[0089]

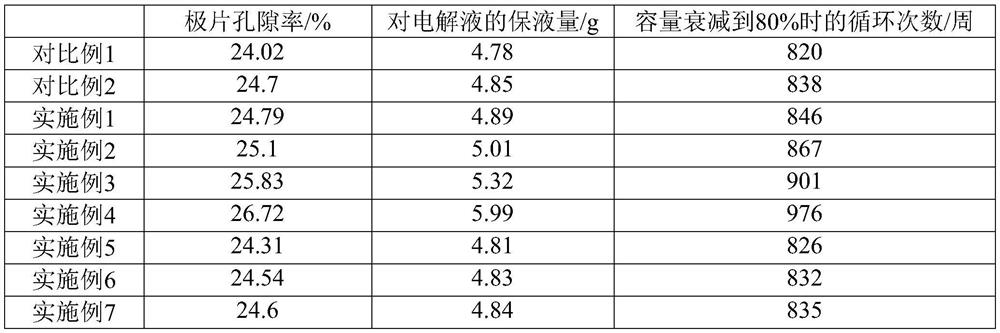

[0090] Table 2 shows the porosity of the negative electrode sheets of the comparative example and the embodiment, the liquid retention capacity of the electrolyte after being assembled into a battery, and the cycle life data.

[0091] The performance data of the battery obtained by the negative electrode sheet and the assembled battery of the comparative example and embodiment of table 2

[0092]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com