Antimony sulfide/graphene composite nano material as well as preparation method and application thereof

A graphene composite, nanomaterial technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as material capacity attenuation, and achieve enhanced conductivity, easy promotion, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the antimony sulfide / graphene composite nanomaterial of the present embodiment comprises the steps:

[0034] Step 1: Ultrasonically disperse graphene in water at normal temperature, then add a mixed aqueous solution of antimony trichloride and hydrochloric acid, and mix well. In the mixed solution, the concentration of graphene is 0.5mg / mL, the concentration of antimony trichloride is 8mmol / L, and the concentration of hydrochloric acid is 0.7mol / L.

[0035] Step 2: Add 0.6 g of a saturated aqueous solution of thioacetamide to the mixed solution obtained in Step 1, and mix evenly.

[0036] In step 3, the mixed solution in step 2 was ultrasonically reacted for 2 hours, and the obtained product was further washed several times with deionized water and absolute ethanol, and then vacuum-dried at 80°C to obtain the antimony sulfide / graphene composite nanomaterial.

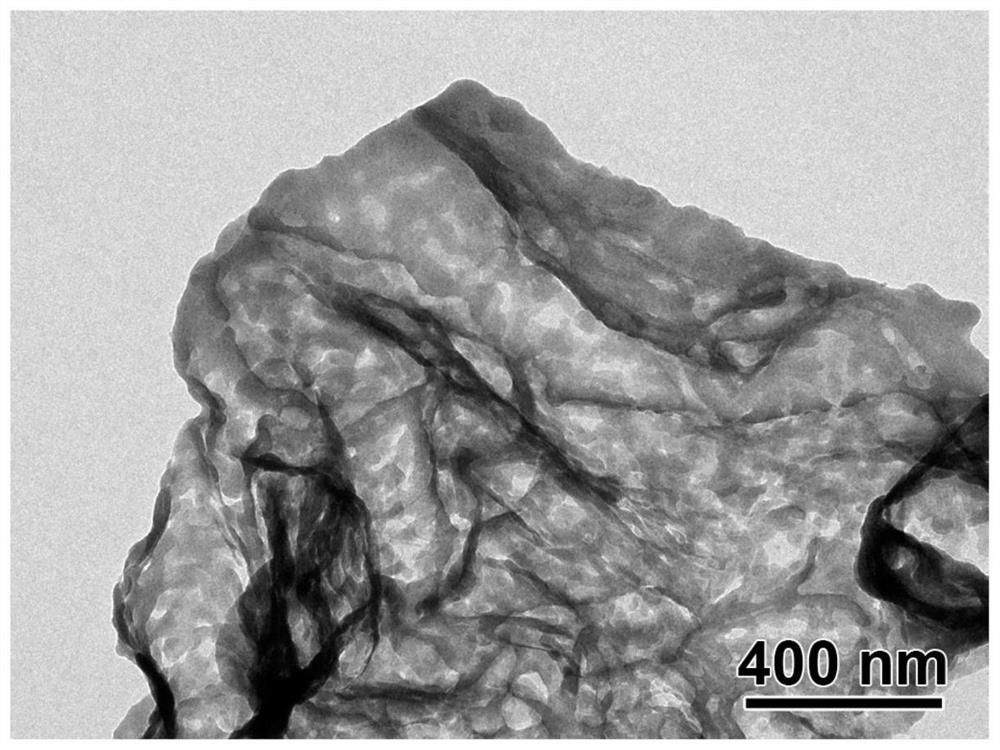

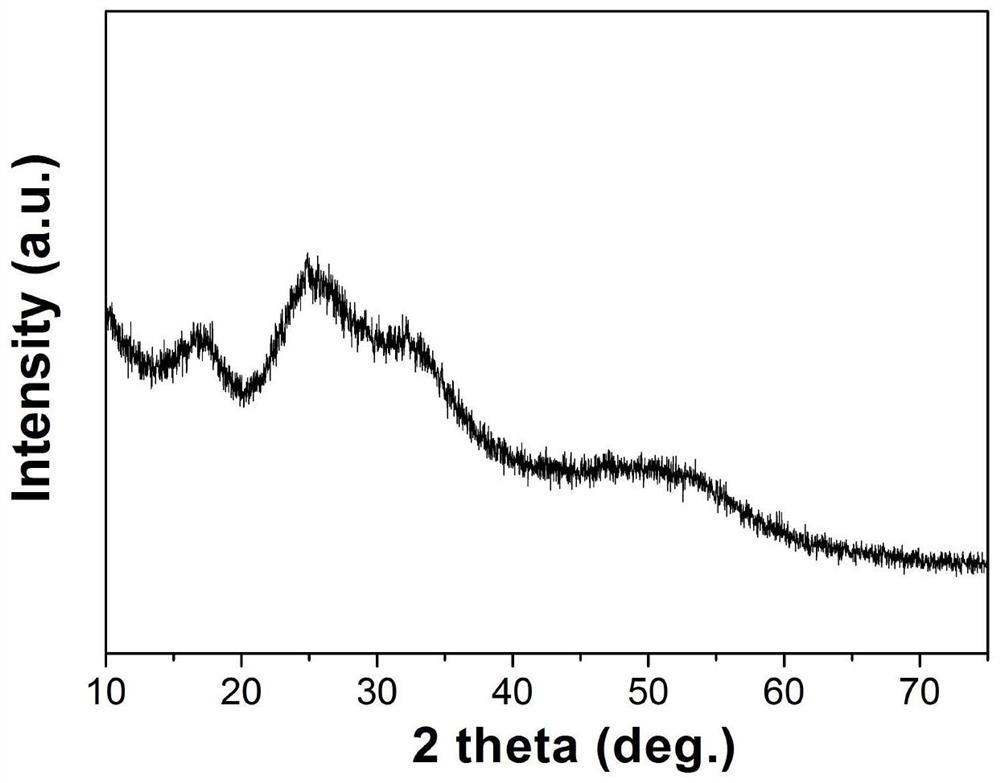

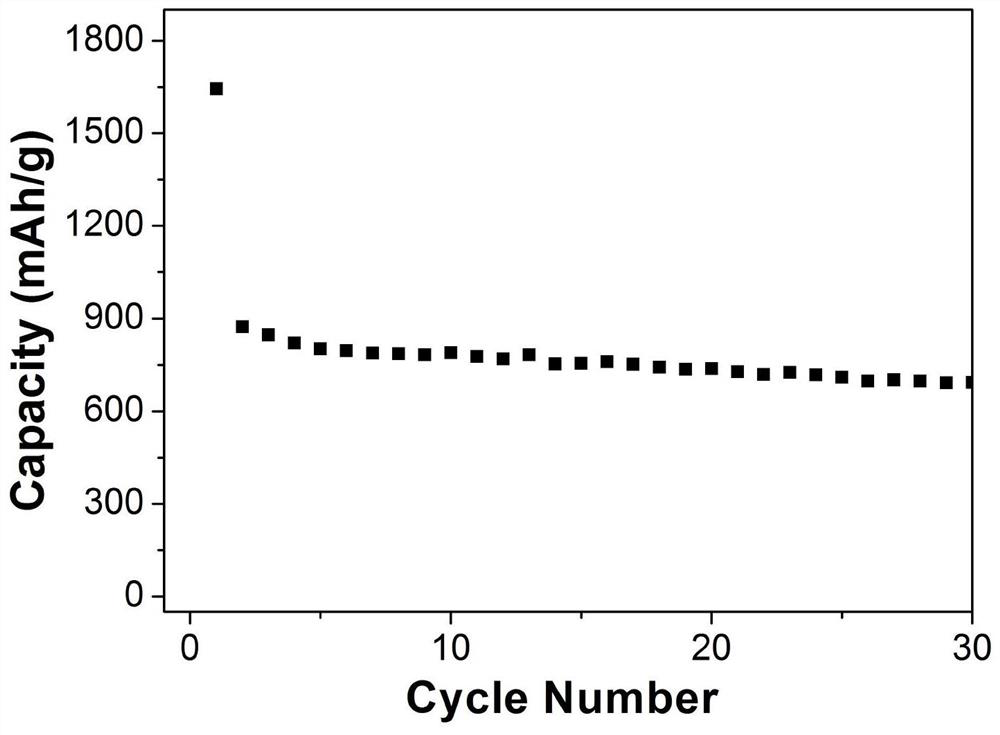

[0037] Such as Figure 1~3 as shown, figure 1 , figure 2 and image 3 The trans...

Embodiment 2

[0039] The preparation method of the antimony sulfide / graphene composite nanomaterial of the present embodiment comprises the steps:

[0040] Step 1, ultrasonically disperse graphene in water, then add a mixed aqueous solution of antimony trichloride and hydrochloric acid, and mix well. In the mixed solution, the concentration of graphene is 1 mg / mL, the concentration of antimony trichloride is 4 mmol / L, and the concentration of hydrochloric acid is about 1 mol / L.

[0041] Step 2: Add 0.3 g of a saturated aqueous solution of thioacetamide to the mixed solution obtained in Step 1, and mix evenly.

[0042] In step 3, the mixed solution in step 2 was ultrasonically reacted for 4 hours, and the obtained product was further washed several times with deionized water and absolute ethanol, and then vacuum-dried at 80°C to obtain a nano-antimony sulfide / graphene composite material.

[0043] The antimony sulfide / graphene composite nanomaterial prepared in Example 2 is similar in struct...

Embodiment 3

[0046] The preparation method of the antimony sulfide / graphene composite nanomaterial of the present embodiment comprises the steps:

[0047] Step 1, ultrasonically disperse graphene in water, then add a mixed aqueous solution of antimony trichloride and hydrochloric acid, and mix well. In the mixed solution, the concentration of graphene is 2 mg / mL, the concentration of antimony trichloride is 2 mmol / L, and the concentration of hydrochloric acid is about 1 mol / L.

[0048] Step 2: Add 1 g of a saturated aqueous solution of thioacetamide to the mixed solution obtained in Step 1, and mix evenly.

[0049] In step 3, the mixed solution in step 2 was ultrasonically reacted for 10 hours, and the obtained product was further washed several times with deionized water and absolute ethanol, and then vacuum-dried at 80°C to obtain a nano-antimony sulfide / graphene composite material.

[0050] The antimony sulfide / graphene composite nanomaterial prepared in Example 3 is similar in structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com