Lead-acid storage battery electrolyte and preparation method thereof

A lead-acid battery, electrolyte technology, applied in lead-acid battery, lead-acid battery construction, electrolyte and other directions, to achieve the effect of inhibiting PCL phenomenon, improving low temperature performance, and improving charging acceptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

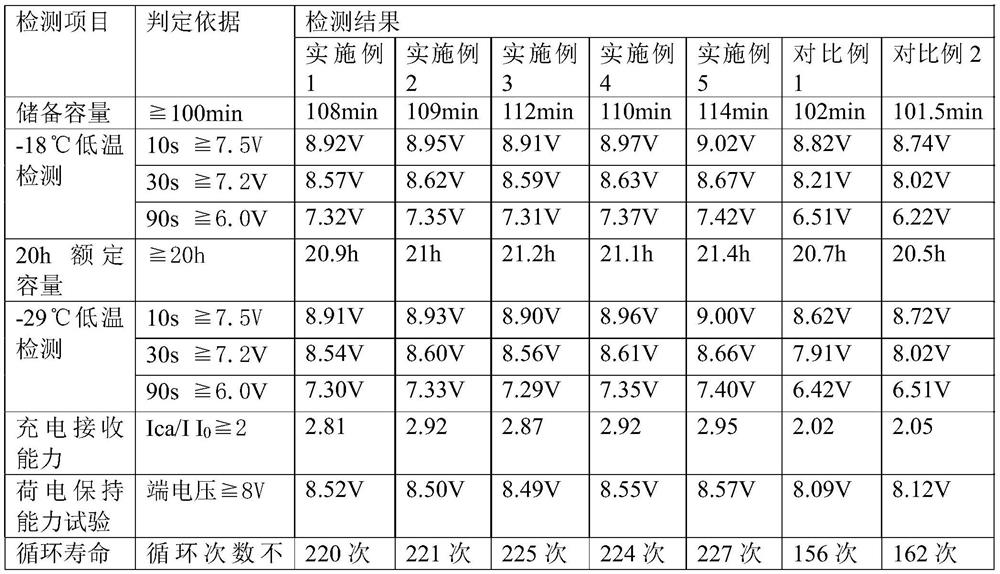

Examples

Embodiment 1

[0032] Raw material composition (parts by weight): 1 part of cobalt sulfate, 1 part of chromium sulfate, 2 parts of ammonium dichromate, 1 part of sodium sulfate, 1 part of magnesium sulfate, 1 part of organic bismuth additive, 5 parts of tannin, 20 parts of phosphoric acid, manna 50 parts of alcohol, 100 parts of polyethylene glycol, 200 parts of deionized water.

[0033] The organic bismuth additive is prepared by the following method: 3mol 2-iodocyanobenzene and 1mol isopropylmagnesium chloride are reacted in 200mL dimethylsulfoxide solution at a low temperature of -20℃ to obtain the corresponding active intermediate, and then 0.8 The mol bismuth trichloride continues to react, and finally tri-(2-cyanophenyl) bismuth is obtained, which is an organic bismuth additive.

[0034] The preparation method of lead-acid battery electrolyte includes the following steps:

[0035] S1. Weigh each raw material according to the formula;

[0036] S2. Heat 1 / 5 of deionized water to 50℃, add 1 / 2 of...

Embodiment 2

[0041] Raw material composition (parts by weight): 3 parts of cobalt sulfate, 2 parts of chromium sulfate, 4 parts of ammonium dichromate, 3 parts of sodium sulfate, 2 parts of magnesium sulfate, 3 parts of organic bismuth additives, 10 parts of tannins, 50 parts of phosphoric acid, and manna 100 parts of alcohol, 300 parts of polyethylene glycol, 400 parts of deionized water.

[0042] The organic bismuth additive is prepared by the following method: 3.2mol 2-iodocyanobenzene and 3mol isopropylmagnesium chloride are reacted in 200mL dimethyl sulfoxide solution at a low temperature of -40°C to obtain the corresponding active intermediate, and then added 1 mol of bismuth trichloride continues to react, and finally tri-(2-cyanophenyl) bismuth is obtained, which is an organic bismuth additive.

[0043] The preparation method of lead-acid battery electrolyte includes the following steps:

[0044] S1. Weigh each raw material according to the formula;

[0045] S2. Heat 1 / 5 of deionized wate...

Embodiment 3

[0050] Raw material composition (parts by weight): 1.5 parts of cobalt sulfate, 1.2 parts of chromium sulfate, 2.5 parts of ammonium dichromate, 1.5 parts of sodium sulfate, 1.1 parts of magnesium sulfate, 1.5 parts of organic bismuth additives, 6 parts of tannins, 25 parts of phosphoric acid, and manna 70 parts of alcohol, 150 parts of polyethylene glycol, 250 parts of deionized water.

[0051] The organic bismuth additive is prepared by the following method: 3.1 mol 2-iodocyanobenzene and 1.5 mol isopropyl magnesium chloride are reacted in 200 mL dimethyl sulfoxide solution at a low temperature of -25°C to obtain the corresponding active intermediate, and then Add 0.9 mol of bismuth trichloride to continue the reaction, and finally prepare tris-(2-cyanophenyl) bismuth, which is an organic bismuth additive.

[0052] The preparation method of lead-acid battery electrolyte includes the following steps:

[0053] S1. Weigh each raw material according to the formula;

[0054] S2. Heat 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com