A kind of preparation method of iron/nitrogen/carbon composite material

A carbon composite material, ferric nitrate technology, applied in carbon preparation/purification, magnetic field/electric field shielding, electrical components, etc., can solve the problems of difficult commercial application, limited wave absorption performance, high material density, and improve microwave The effect of absorption strength, low cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

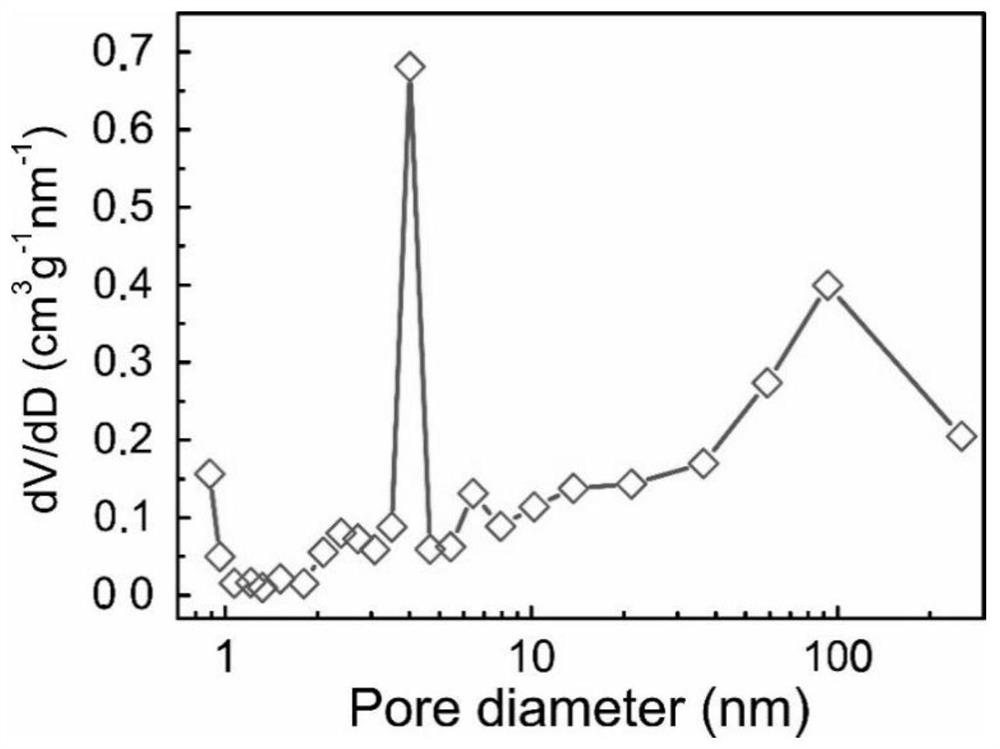

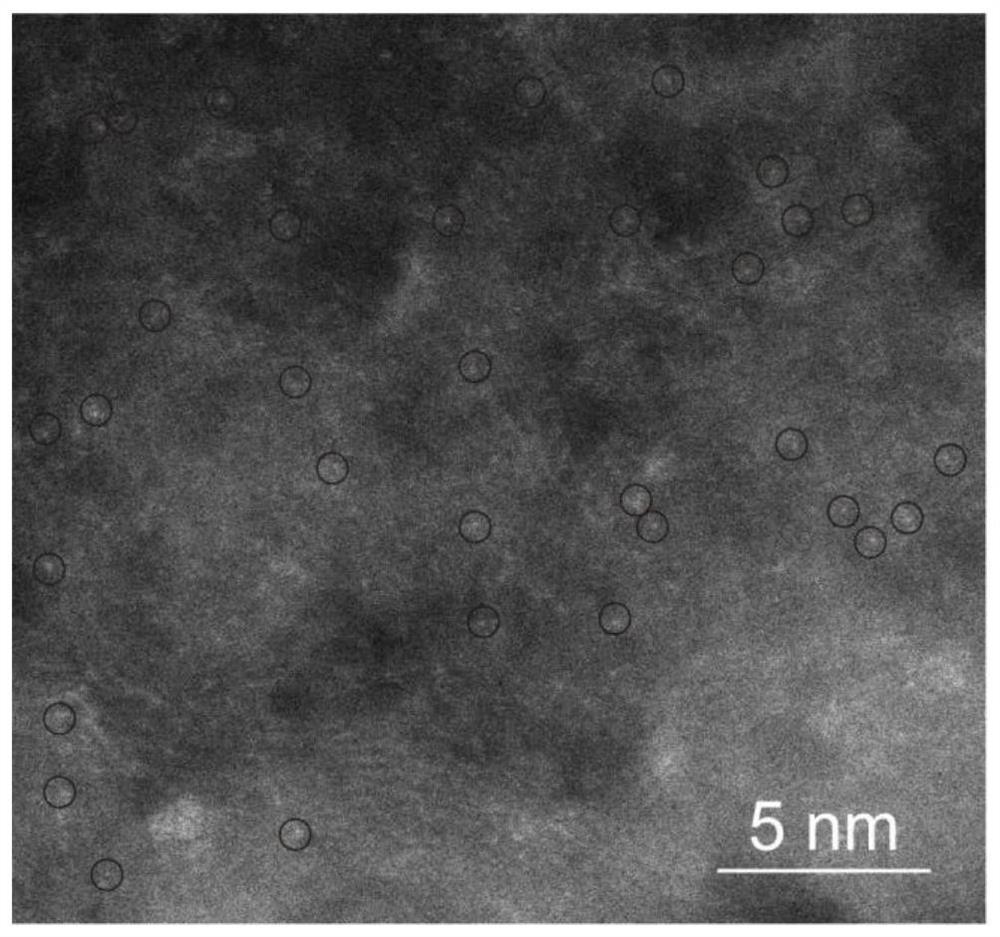

[0022] (1) Disperse silica balls, agar, urea, and ferric nitrate nine water with a mass ratio of 1:2:12:1.5 in 40 parts of deionized water, then ultrasonicate the mixed solution for 10 minutes to disperse the solute evenly, and then The solution was heated and stirred at 100°C for 50 minutes until the generation of bubbles stopped;

[0023] (2) The mixed solution in (1) was left to stand at room temperature for 4 hours, and it was cooled to form a gel; the formed gel block was quickly frozen with liquid nitrogen, placed in a freeze dryer, and lyophilized for 24 hours, Finally, a dry block is formed;

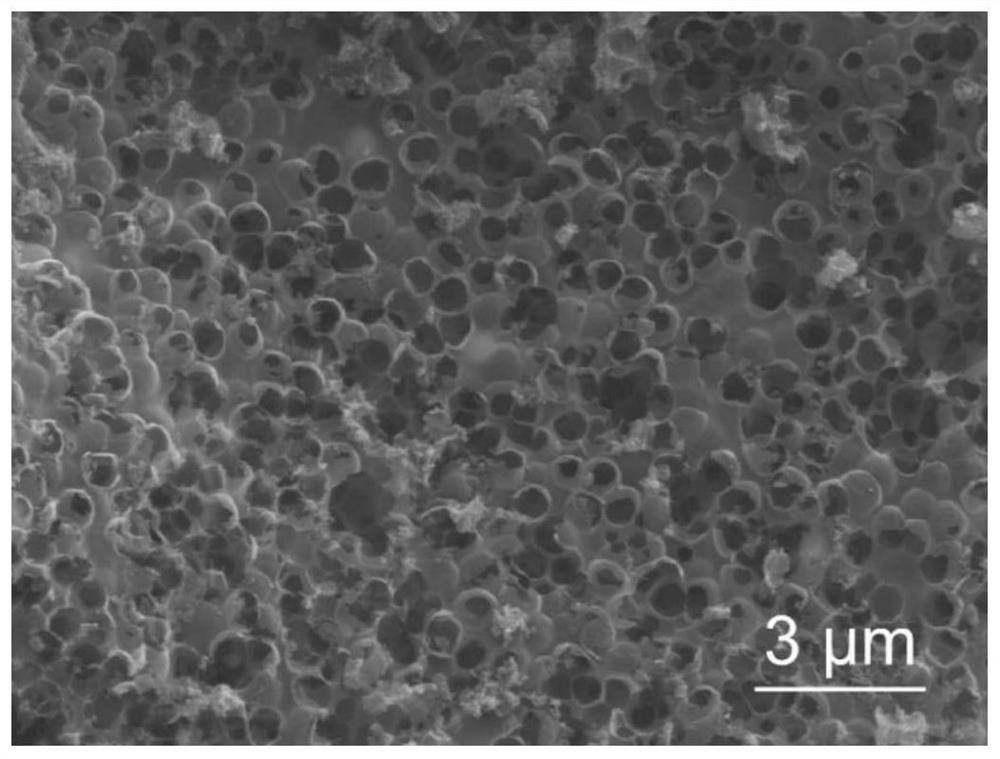

[0024] (3) Move the freeze-dried block in (2) to a crucible, place it in a tube furnace, and perform high-temperature sintering at 900°C for 4 hours under an argon atmosphere, and then sinter the sintered material with hydrogen fluorine Acid corrosion for 12h;

[0025] (4) The corroded product was washed several times with ethanol and deionized water, then dried at 60° C., and ...

Embodiment 2

[0029] Disperse silica balls, agar, urea, and ferric nitrate nine water with a mass ratio of 1:2:12:1 in 40 parts of deionized water, and the rest are the same as in Example 1.

[0030] The prepared material was used to prepare the absorbing sample, and the measured maximum reflection loss value was -40.6dB, the effective bandwidth was 4.1GHz, the material filling mass was only 10%, and the thickness was 2.5mm.

Embodiment 3

[0032] The raw materials and preparation process of this embodiment are the same as those in Example 1, except that the amount of ferric nitrate nine water is 3 parts.

[0033] The prepared material is used to prepare the absorbing sample, and the measured maximum reflection loss value is -55.4dB, the effective bandwidth is 4.8GHz, the material filling mass is only 20%, and the thickness is 1.65mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com