Preparation method of platinum nanowire particle catalyst

A technology of platinum nanowires and particles, which is applied in the field of platinum nanowire particle catalysts, can solve problems affecting the application of technology, achieve precise reaction process, improve the effect of wide scale range, and reduce platinum loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

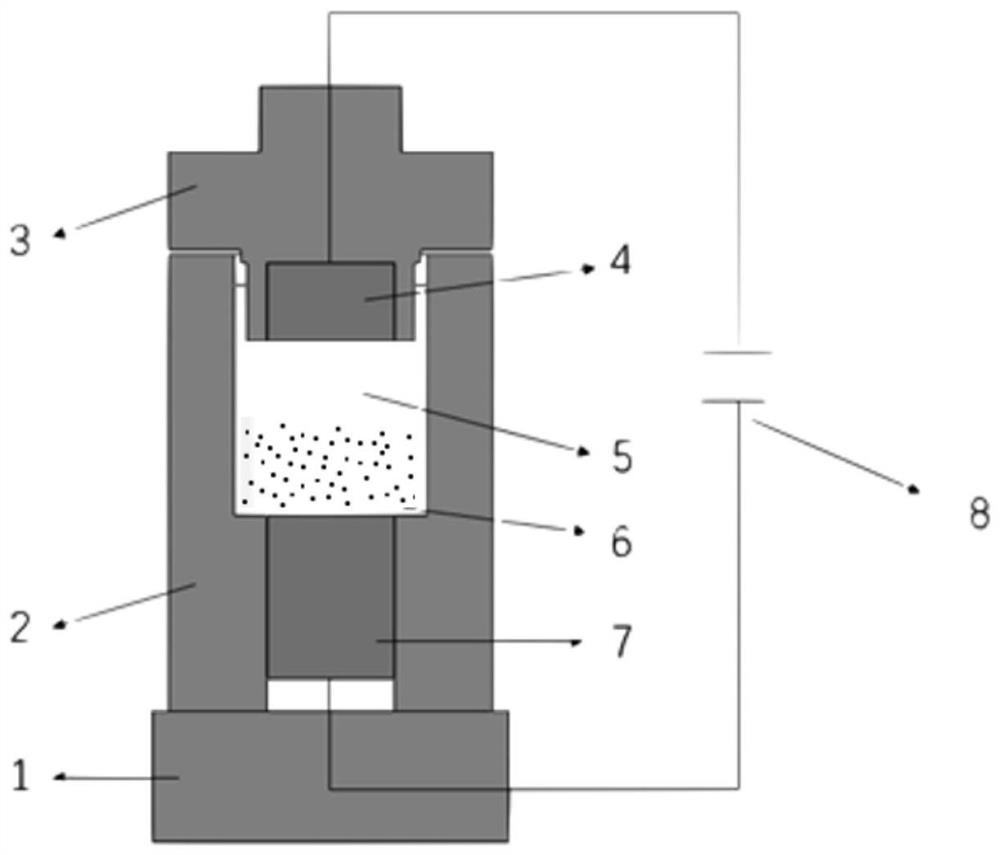

Method used

Image

Examples

Embodiment 1

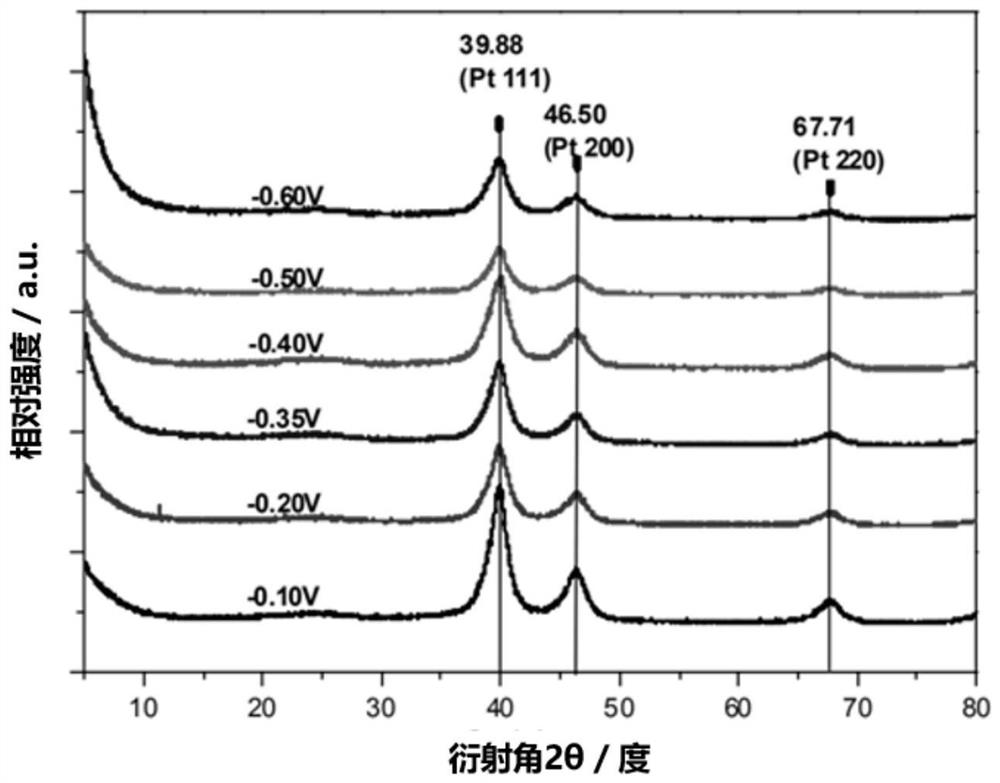

[0030] (1) 10mg conductive carbon black (specific surface area 1400m 2 / g), 1mL H 2 PtCl 6 Solution (concentration: 50mmol / L), 0.4mL formic acid solution (concentration: 1.4mol / L), 0.5mL PVP (concentration: 10mg / mL) and 12mL deionized water are configured as a reaction slurry, and the slurry is mixed evenly by ultrasonic treatment ;

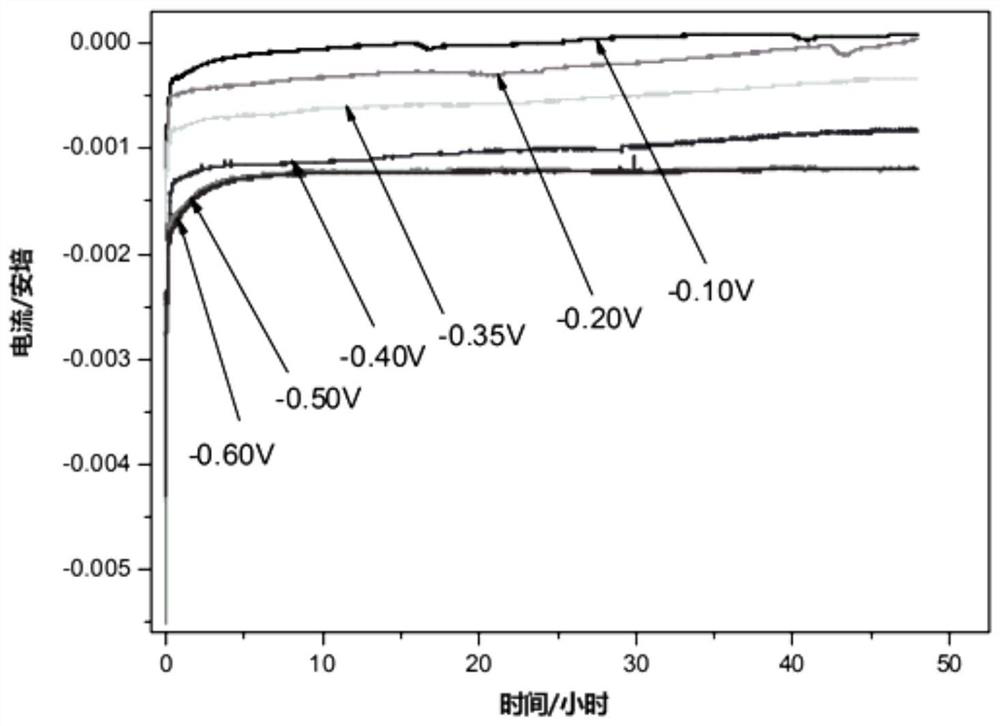

[0031] (2) Pour the prepared slurry into the electrolytic cell reactor, place it in an environment of 20° C. and apply a DC electric field of -0.10 V for 48 hours to deposit platinum particles;

[0032] (3) Take out the reacted slurry, filter it, wash it repeatedly with deionized water for 2-3 times, and dry it at 80° C. to obtain platinum nanowire particles (Pt-NWs) catalyst powder.

Embodiment 2

[0034] (1) 10mg conductive carbon black (specific surface area 1400m 2 / g), 1mL H 2 PtCl 6 Solution (concentration: 50mmol / L), 0.4mL formic acid solution (concentration: 1.4mol / L), 0.5mL PVP (concentration: 10mg / mL) and 12mL deionized water are configured as a reaction slurry, and the slurry is mixed evenly by ultrasonic treatment ;

[0035] (2) Pour the prepared slurry into the electrolytic cell reactor, place it in an environment of 20° C. and apply a DC electric field of -0.20 V for 48 hours to deposit platinum particles;

[0036] (3) Take out the reacted slurry, filter it, wash it repeatedly with deionized water for 2-3 times, and dry it at 80° C. to obtain platinum nanowire particles (Pt-NWs) catalyst powder.

Embodiment 3

[0038] (1) 10mg conductive carbon black (specific surface area 1400m 2 / g), 1mL H 2 PtCl 6 Solution (concentration: 50mmol / L), 0.4mL formic acid solution (concentration: 1.4mol / L), 0.5mL PVP (concentration: 10mg / mL) and 12mL deionized water are configured as a reaction slurry, and the slurry is mixed evenly by ultrasonic treatment ;

[0039] (2) Pour the prepared slurry into the electrolytic cell reactor, place it in an environment of 20° C. and apply a DC electric field of -0.35 V for 48 hours to deposit platinum particles;

[0040](3) Take out the reacted slurry, filter it, wash it repeatedly 2 to 3 times with deionized water, and dry it at 80°C to obtain platinum nanoparticles (Pt-NPs) and platinum nanowire particles (Pt-NPs) -NWs) mixed catalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com