Ceramic glaze with satin texture, preparation method and ceramic rock plate using same

A ceramic glaze and texture technology, which is applied in the field of building ceramic materials, can solve the problems of narrow firing range, single texture of glazed surface, and high production cost, and achieve wide firing range, excellent comprehensive performance of glazed surface, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

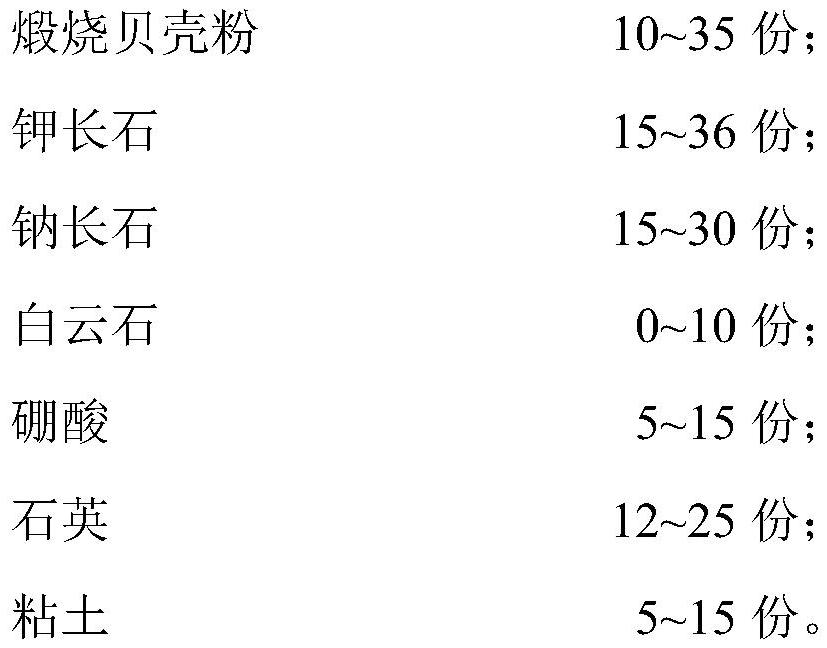

[0027] A kind of ceramic glaze of satin texture, it is characterized in that comprising the following components in parts by weight of raw materials:

[0028]

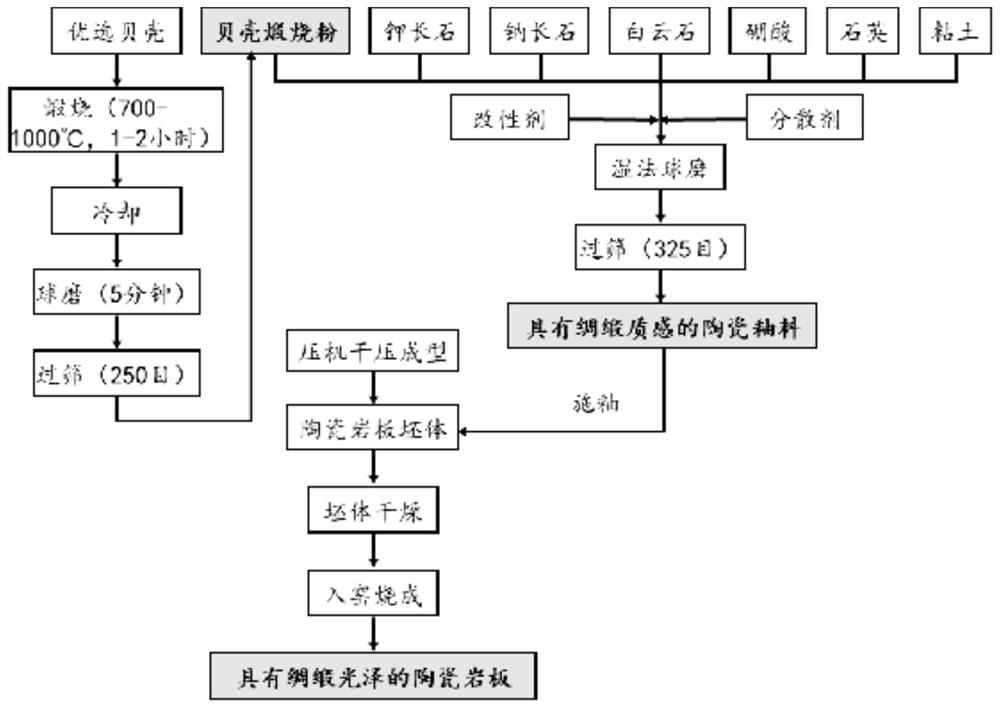

[0029] The preparation method is attached figure 1 shown:

[0030] 1) choose shells: 25 parts of oysters, 25 parts of cockles, 25 parts of clams, 25 parts of clams are mixed in parts by weight of raw materials, and the chemical composition of shells before calcining is 0.6 part of Na. 2 O, 0.4 parts of Al 2 O 3 , 0.4 parts of SiO 2 , 55.4 parts of CaO, 0.2 parts of P 2 O 5 , 43 burns;

[0031] 2) calcining: the shells of step 1) are placed in a furnace, the temperature increase rate from room temperature to 450°C is controlled to be 2°C / min, the temperature increase rate from 450 to 780°C is 5°C / min, and the temperature is calcined at 780°C. 2h, then ball-milled and passed through a 250-mesh sieve to obtain calcined shell powder;

[0032] 3) Glaze making: mix the components uniformly by weight of raw materials...

Embodiment 2

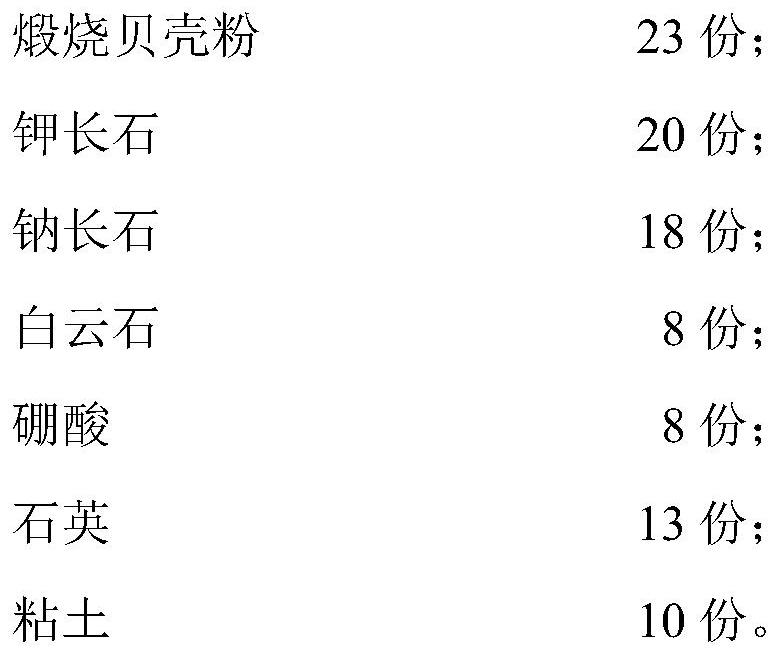

[0047] A kind of ceramic glaze of satin texture, it is characterized in that comprising the following components in parts by weight of raw materials:

[0048]

[0049] Preparation:

[0050] 1) Select shells: mix 50 parts of oysters and 50 parts of mussels by weight of raw materials, and the chemical composition of the shells before calcination is 0.4 parts of Na 2 O, 0.2 parts of Al 2 O 3 , 0.5 parts of SiO 2 , 55.6 parts of CaO, 0.3 parts of P 2 O 5 , 43 burns;

[0051] 2) Calcination: place the shell of step 1) in a furnace, control the temperature rise rate from room temperature to 450°C to be 2°C / min, and the temperature rise rate from 450 to 1000°C to be 5°C / min, and calcine at a temperature of 1000°C 1h, then ball-milled and passed through a 250-mesh sieve to obtain calcined shell powder;

[0052] 3) Mix the components uniformly in parts by weight of the raw materials, add 0.5 part of modifier and 0.5 part of dispersant, carry out wet ball milling, after ball m...

Embodiment 3

[0055] A kind of ceramic glaze of satin texture, it is characterized in that comprising the following components in parts by weight of raw materials:

[0056]

[0057] Preparation:

[0058] 1) choose shells: 75 parts of cockles and 25 parts of clams are mixed by raw material weight parts, and the chemical composition of shells before calcining is 0.8 parts of Na 2 O, 0.2 parts of Al 2 O 3 , 0.1 part of SiO 2 , 55.9 parts of CaO, 43 parts of loss on ignition;

[0059] 2) calcination: the shells of step 1) are placed in a furnace, the temperature rise rate of controlling room temperature to 450 ℃ is 2 ℃ / min, and the heating rate of 450~850 ℃ is 5 ℃ / min, and calcined under the temperature condition of 850 ℃ 1.5h, then ball-milled and passed through a 250-mesh sieve to obtain calcined shell powder;

[0060] 3) Mix the components uniformly in parts by weight of raw materials, add 0.3 part of modifier and 2 parts of dispersant, carry out wet ball milling, after ball milling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com