Method for strengthening interface bonding of GNPs/Ti composite by directionally growing TiBw

A composite material and directional growth technology, which is applied in the field of directional growth of TiBw to strengthen the interface bonding of GNPs/Ti composite materials, can solve problems such as optimizing the interface structure of GNPs/Ti composite materials, deteriorating the interface bonding characteristics of composite materials, and chaotic TiBw distribution. Good application prospects, solve the mismatch between strength and plasticity, and improve the effect of strong-plasticity matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

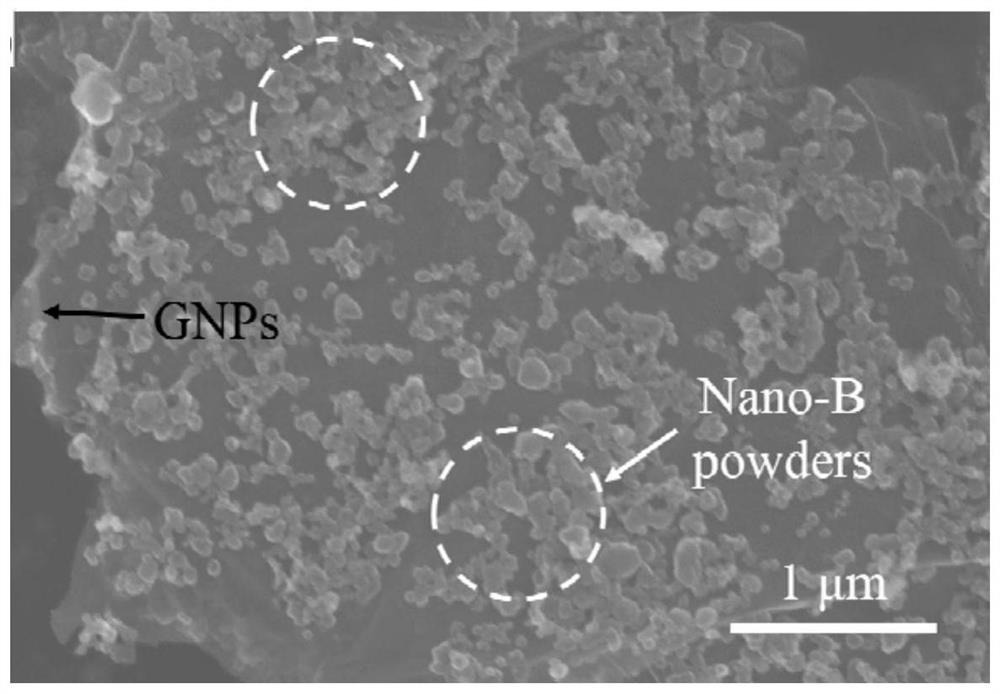

[0046](1) B nano powder and GNPs are evenly mixed

[0047] B nanopowder and GNPs were accurately weighed and dispersed in absolute ethanol at a mass ratio of 1:100, and ultrasonically dispersed for 0.1h under an ultrasonic power of 500W to obtain a B@GNPs solution;

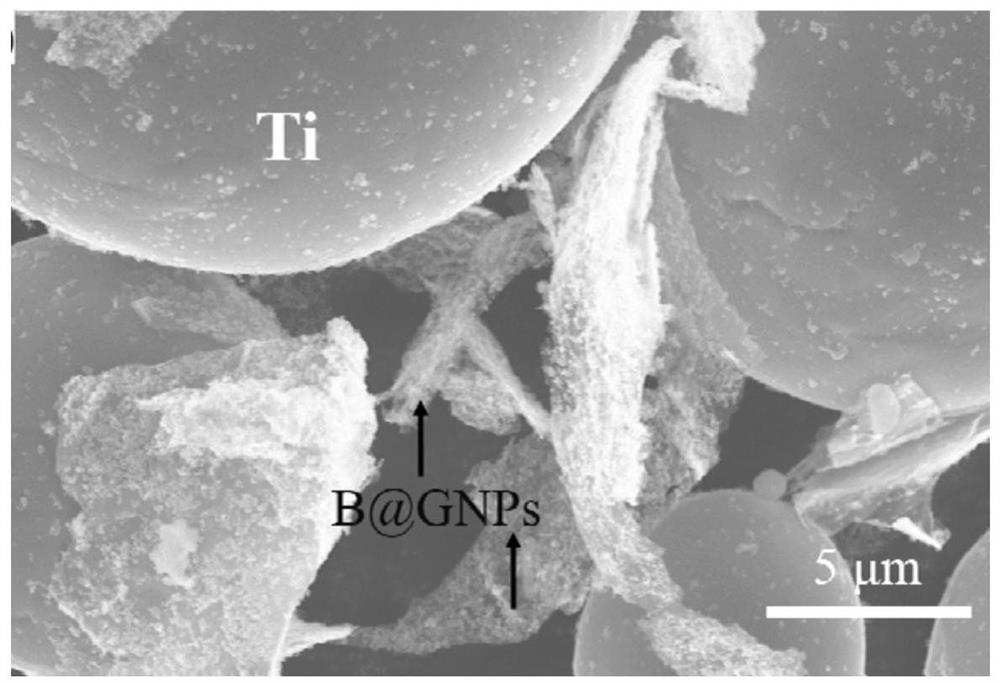

[0048] (2) Preparation of B@GNPs / Ti composite powder

[0049] Spherical pure Ti powder with an average particle size of 30 μm was added to the B@GNPs solution, stirred magnetically for 5 min at a stirring rate of 500 r / min, filtered and dried to obtain a B@GNPs / Ti composite powder; wherein, GNPs were The mass fraction in B@GNPs / Ti composite powder is 1%;

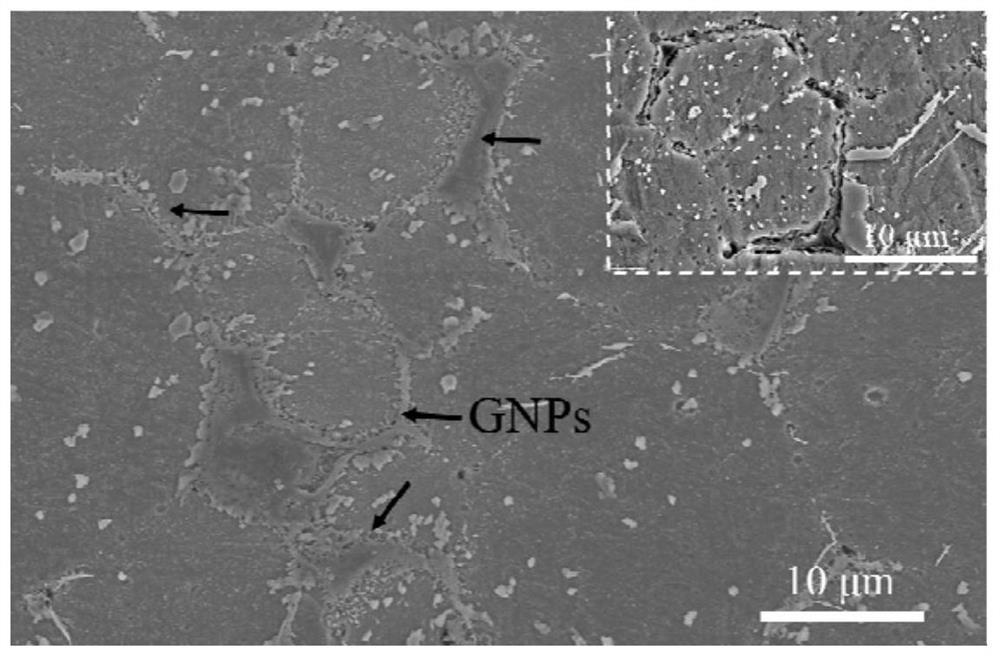

[0050] (3) Sintering

[0051] Put the B@GNPs / Ti composite powder into a heat-resistant steel mold, use the SPS device to raise the temperature to 600°C (measurement temperature at the temperature measurement hole of the steel mold), and apply a pressure of 100MPa at the same time, keep the temperature at 600°C and 100MPa 5min, and then cooled with the furnace...

Embodiment 2

[0056] (1)TiB 2 Nano powder mixed with GNPs evenly

[0057] TiB 2 The nanopowder and GNPs were accurately weighed and dispersed in absolute ethanol at a mass ratio of 1:20, and ultrasonically dispersed for 1 h at an ultrasonic power of 300 W to obtain TiB 2 @GNPs solution;

[0058] (2)TiB 2 Preparation of @GNPs / Ti6Al4V Composite Powder

[0059] Flake Ti6Al4V alloy powder with an average particle size of 30 μm was added to TiB 2 In the @GNPs solution, after magnetic stirring at a stirring rate of 200r / min for 60min, filter and dry to obtain TiB 2 @GNPs / Ti6Al4V composite powder; among them, GNPs in TiB 2 The mass fraction of @GNPs / Ti6Al4V composite powder is 0.01%;

[0060] (3) Sintering

[0061] TiB 2 The @GNPs / Ti6Al4V composite powder is put into a heat-resistant steel mold, and the temperature is raised to 700°C (measured temperature at the temperature measuring hole of the steel mold) by the SPS device, and a pressure of 350MPa is applied at the same time, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com