Preparation method of biological hydrogen feed additive

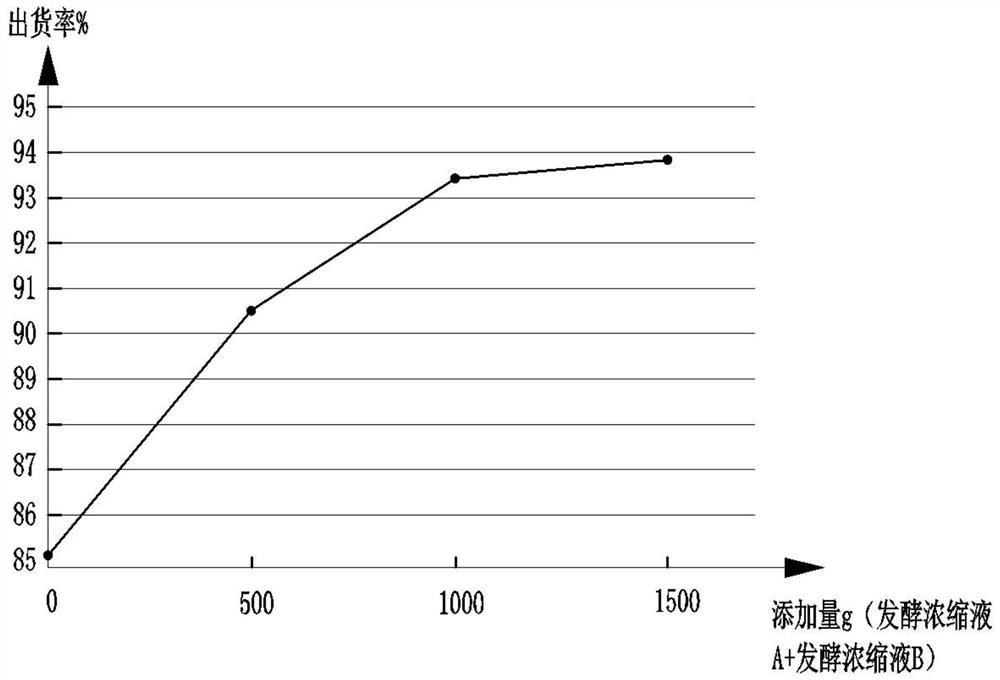

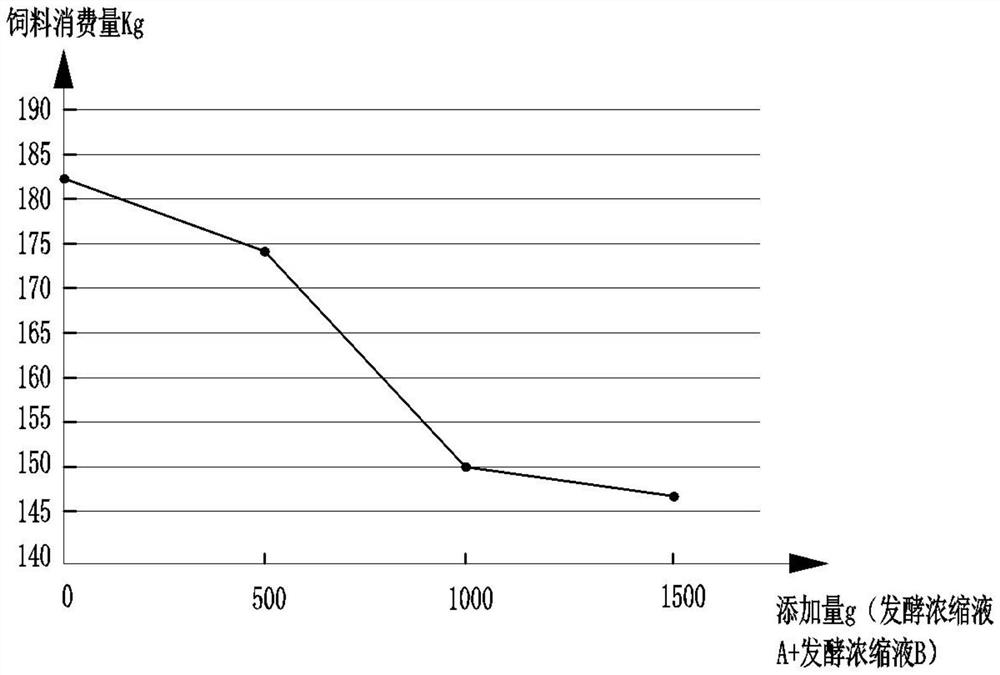

A feed additive and hydrogen technology, which is applied in the field of preparation of biological water feed additives, can solve the problems of harming human beings and the environment, and the quality decline of livestock and poultry products, and achieve the effects of short production cycle, reduced consumption, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

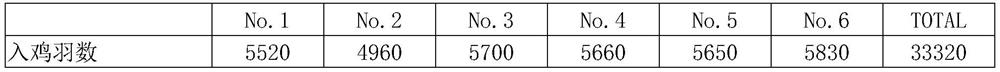

Examples

Embodiment 1

[0027] A preparation method of biological water element feed additive, the preparation method is specifically as follows:

[0028] (1) Selection of bacterial strains and medium:

[0029] Bacterial strain A: Bacillus subtilis with preservation number CGMCC No.18614, medium weight percent: peptone 0.5-0.8%, yeast extract powder 0.25-0.5%, sodium chloride 0.25-0.5%, glucose 0.5-0.8% And the remaining distilled water, the pH value is 7.2, and then cultivated at a constant temperature of 30-35°C for 48-55h to obtain the fermentation concentrate A, wherein the number of strain A is greater than 10 9 / ml;

[0030] The preservation information is as follows:

[0031] Classification name: Bacillus subtilis

[0032] Name of depository unit: General Microbiology Center of China Committee for the Collection of Microorganisms

[0033] Address of Preservation Unit: No. 3, Yard No. 1, Beichen West Road, Chaoyang District, Beijing

[0034] Deposit date: September 24, 2019

[0035] Depos...

Embodiment 2

[0057] The difference between this embodiment and Example 1 is: the preparation of fermented solids in step (2):

[0058] Fermentation solids A: Mix and stir the fermentation concentrate A, defatted rice bran, wheat bran, corn flour, glucose and hydrogen water at a weight ratio of 2:1:10:5:1:2 for 8 to 12 minutes, then heat at 30°C to Insulate and ferment at 35°C for 100-120 hours, including 1000g of fermentation concentrate A, 500g of defatted rice bran, 5000g of wheat bran, 2500g of corn flour, 500g of glucose and 1000g of hydrogen water, of which the concentration of hydrogen water is 1-1.2ppm, and defatted rice bran , wheat bran, and corn flour have a water content of 8% to 12%;

[0059] Fermentation solids B: Mix and stir the fermentation concentrate B, defatted rice bran, wheat bran, corn flour, glucose and hydrogen water at a weight ratio of 2:6:5:4:1:2 for 8 to 12 minutes, then heat at 30°C to Insulate and ferment at 35°C for 100-120 hours; including 1000g of fermenta...

Embodiment 3

[0063] The difference between this embodiment and Example 1 is: the preparation of fermented solids in step (2):

[0064] Fermentation solids A: Mix and stir the fermentation concentrate A, defatted rice bran, wheat bran, corn flour, glucose and hydrogen water at a weight ratio of 3:1:10:5:1:2 for 8 to 12 minutes, then heat at 30°C to Insulate and ferment at 35°C for 100-120 hours, including 1500g fermentation concentrate A, 500g defatted rice bran, 5000g wheat bran, 2500g corn flour, 500g glucose and 1000g hydrogen water, the concentration of hydrogen water is 1-1.2ppm, defatted rice bran , wheat bran, and corn flour have a water content of 8% to 12%;

[0065] Fermentation solids B: Mix and stir the fermentation concentrate B, defatted rice bran, wheat bran, corn flour, glucose and hydrogen water at a weight ratio of 3:6:5:4:1:2 for 8 to 12 minutes, then heat at 30°C to Insulate and ferment at 35°C for 100-120 hours; including 1500g fermentation concentrate B, 3000g defatted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com