Preparation method and application of TiO2 photocatalytic nano-film

A nano-film, photocatalytic technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of uneven film preparation thickness and pore distribution, affecting the catalytic performance of photocatalytic films, acid resistance Alkali corrosion performance is poor and other problems, to achieve the effect of reducing application cost, high stretchability, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

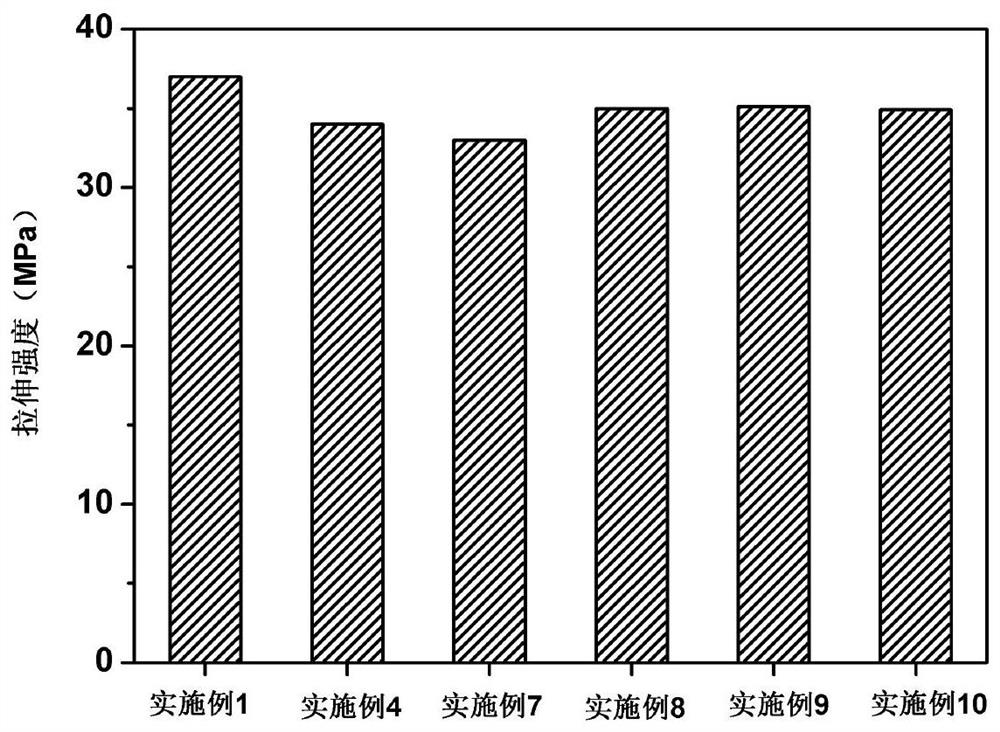

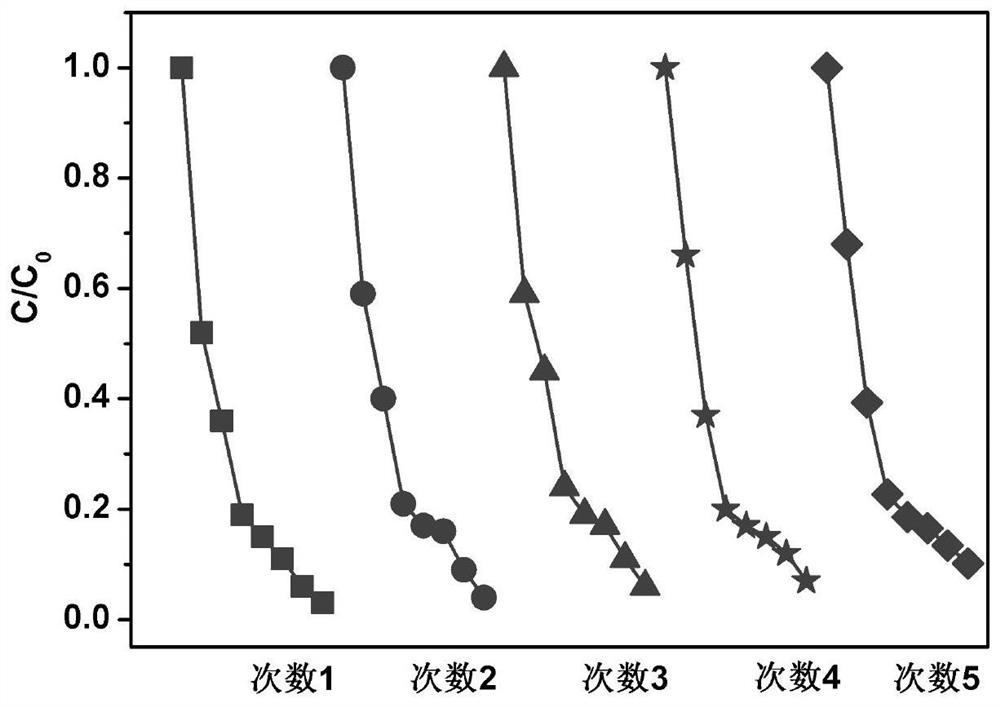

Embodiment 1

[0032] A kind of TiO 2 A method for preparing a photocatalytic nano film, comprising the following steps:

[0033] S1: Add chlorinated polyvinyl chloride (CPVC) to the beaker, and then add N,N-dimethylformamide, where the mass volume ratio of CPVC to N,N-dimethylformamide is 1:20g / mL , stir to make it fully dissolve, add it to the liquid inlet pump of electrospinning, adjust the voltage of the equipment to 29kV, and the injection rate is 12mL / min to obtain a nano film of CPVC.

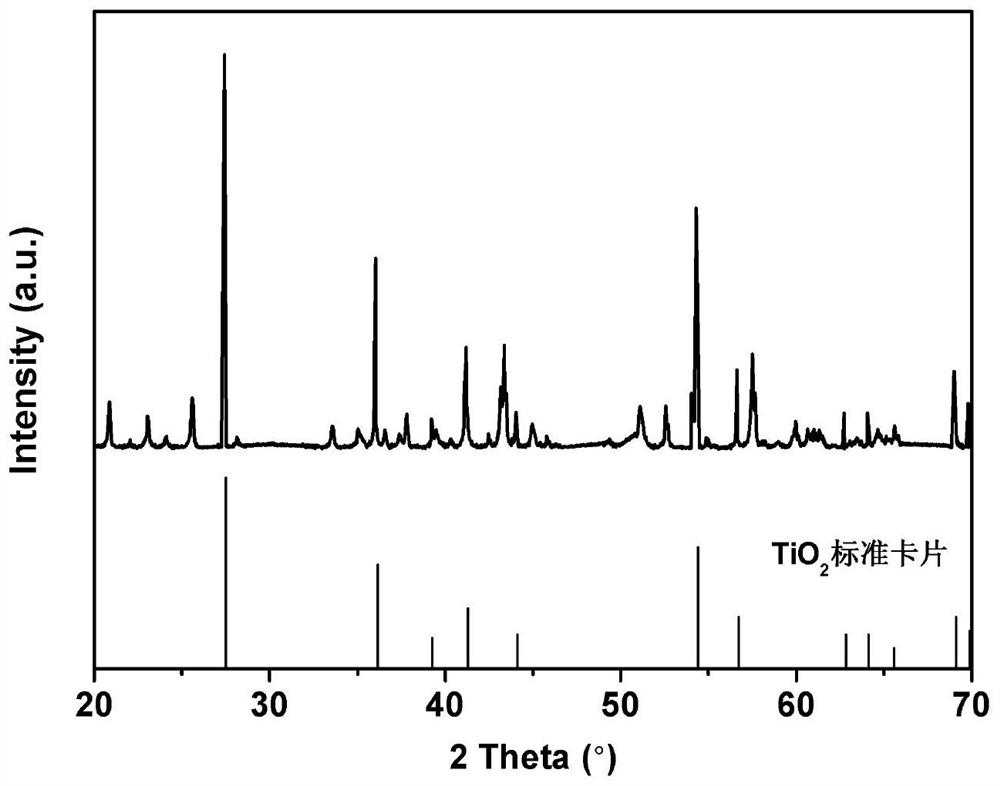

[0034] S2: TiO 2 Add it to another beaker, then add isopropanol, wherein the mass volume ratio of the added substance is 1:8g / mL, then place the beaker on a heating device, raise the temperature to 30°C and stir for 2h to obtain TiO 2 solution.

[0035]S3: Place the monolayer CPVC nano film obtained in step S1 into a glass dish, and then place the TiO obtained in step S2 2 The solution was slowly drained into a glass dish with a glass rod, and left to stand for 2 hours. The film was taken out, plac...

Embodiment 2

[0038] A kind of TiO 2 A method for preparing a photocatalytic nano film, comprising the following steps:

[0039] S1: Add chlorinated polyvinyl chloride (CPVC) to the beaker, and then add N,N-dimethylformamide, where the mass volume ratio of CPVC to N,N-dimethylformamide is 1:28g / mL , stir to make it fully dissolve, add it to the liquid inlet pump of electrospinning, adjust the voltage of the equipment to 29kV, and the injection rate is 12mL / min to obtain a nano film of CPVC.

[0040] S2: TiO 2 Add it to another beaker, then add isopropanol, wherein the mass volume ratio of the added substance is 1:15g / mL, then place the beaker on a heating device, raise the temperature to 45°C and stir for 8h to obtain TiO 2 solution.

[0041] S3: Place the monolayer CPVC nano film obtained in step S1 into a glass dish, and then place the TiO obtained in step S2 2 The solution was slowly drained into a glass dish with a glass rod, and left to stand for 6 hours. The film was taken out, pl...

Embodiment 3

[0043] A kind of TiO 2 A method for preparing a photocatalytic nano film, comprising the following steps:

[0044] S1: Add chlorinated polyvinyl chloride (CPVC) to the beaker, and then add N,N-dimethylformamide, where the mass volume ratio of CPVC to N,N-dimethylformamide is 1:25g / mL , stir to make it fully dissolve, add it to the liquid inlet pump of electrospinning, adjust the voltage of the equipment to 29kV, and the injection rate is 12mL / min to obtain a nano film of CPVC.

[0045] S2: TiO 2 Add it to another beaker, then add isopropanol, wherein the mass volume ratio of the added substance is 1:10g / mL, then place the beaker on a heating device, raise the temperature to 40°C and stir for 6h to obtain TiO 2 solution.

[0046] S3: Place the monolayer CPVC nano film obtained in step S1 into a glass dish, and then place the TiO obtained in step S2 2 The solution was slowly drained into a glass dish with a glass rod, and left to stand for 4 hours. The film was taken out, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com