Method for preparing granular activated carbon from coal semicoke

A technology of granular activated carbon and semi-coke, which is applied in the field of coal semi-coke to prepare granular activated carbon, can solve the problems of large consumption of activator, time-consuming, large energy consumption, etc., so as to reduce production costs and equipment maintenance costs, reduce consumption, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

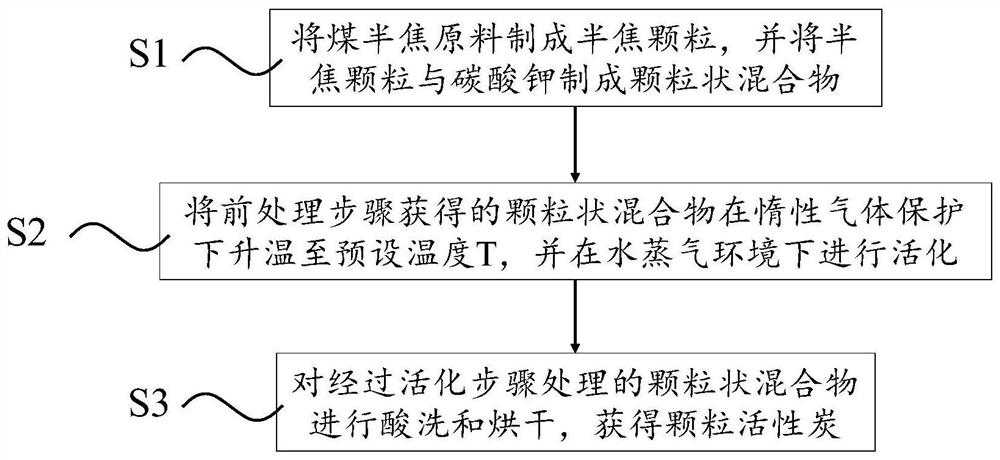

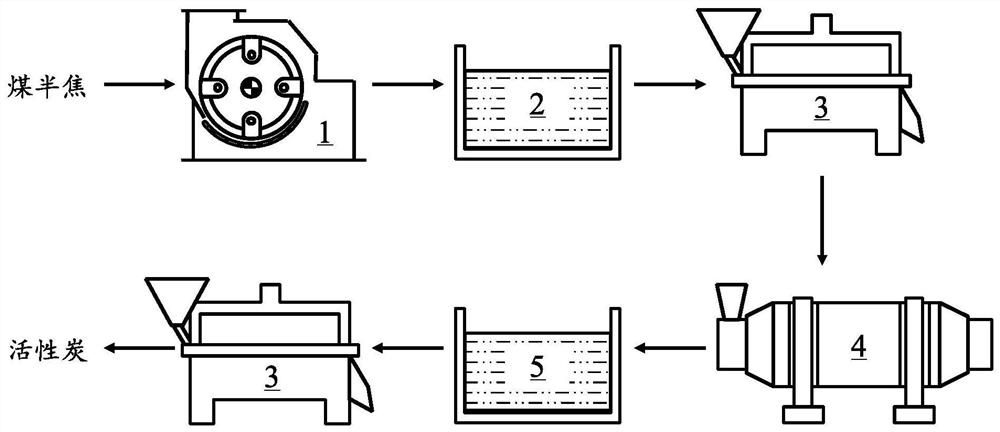

[0030] Such as figure 1 As shown, the present embodiment provides a kind of preparation method of activated carbon, comprising steps:

[0031] S1 pretreatment step, the coal semi-coke raw material is made into semi-coke particles, and the semi-coke particles and potassium carbonate are made into a granular mixture; S2 activation step, the pre-treated particles are heated to a preset temperature under the protection of an inert gas After T, water vapor is passed through to activate; S3 post-treatment step, pickling and drying the mixture treated in the activation step to obtain granular activated carbon.

[0032] In this embodiment, potassium carbonate and semi-coke particles are used for chemical activation. Compared with potassium hydroxide commonly used in the prior art, potassium carbonate is less corrosive and less costly, which not only reduces the maintenance cost of activation equipment , and reduces the cost of use, enabling large-scale production of activated carbon....

Embodiment

[0046] Example ①: 10-20 mesh coal semi-coke particles obtained by crushing and screening and potassium carbonate powder with a mass ratio of 0.2 were fully impregnated for 12 hours, and then dried at 120° C. for 4 hours. The pretreated particles were sent to the activation furnace, and the temperature was raised to 800°C at a rate of 10°C / min under the protection of nitrogen, and the activation temperature was 800°C, and the water vapor mass ratio was 1.2 for joint activation for 1 hour. Reduce to normal temperature, pickle with dilute hydrochloric acid and dry to obtain activated carbon products. The yield of the activated carbon product is 47.1%, and the specific surface area is 671.7m 2 / g, iodine value 825.9mg / g, phenol adsorption value 105.2mg / g. In addition to being applied to the adsorption of pollutants in water, the product has also achieved good results in flue gas desulfurization. 2 The adsorption capacity was 31.2 mg / g.

[0047] Example ②: The 10-20 mesh coal se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com