Method for producing ultrahigh-purity pig iron with iron bath smelting reduction process

A technology of iron bath melting and reduction method, applied in the field of melting reduction metallurgy, can solve problems such as restricting the relationship between the production and supply of high-purity pig iron and ultra-high-purity pig iron, high phosphate ore and vanadium-titanium ore are not effectively developed and utilized, and the like, To achieve the effect of improving the purity of molten iron, being conducive to environmental protection and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a method for producing ultra-high-purity pig iron by iron bath smelting reduction, comprising the following steps:

[0070] (1) Screen the raw materials for the furnace, including mineral powder, coal powder, dolomite powder and limestone powder

[0071] The conditions that each raw material needs to meet are as follows:

[0072] Mineral powder: the grade of iron in the mineral powder is not lower than 58wt%, the content of phosphorus is not higher than 0.2wt%, the content of sulfur is not higher than 0.05wt%, the particle size is not higher than 20mm, and the particle size is not lower than 4mm in the total mineral powder The content in powder is not higher than 10wt%;

[0073] Coal powder: Coal is crushed and ground by a coal mill to obtain coal powder. The fixed carbon content in coal powder is not less than 75wt%, the volatile content is 5-15wt%, the sulfur content is not higher than 0.8wt%, and the particle size is not higher than 10mm , ...

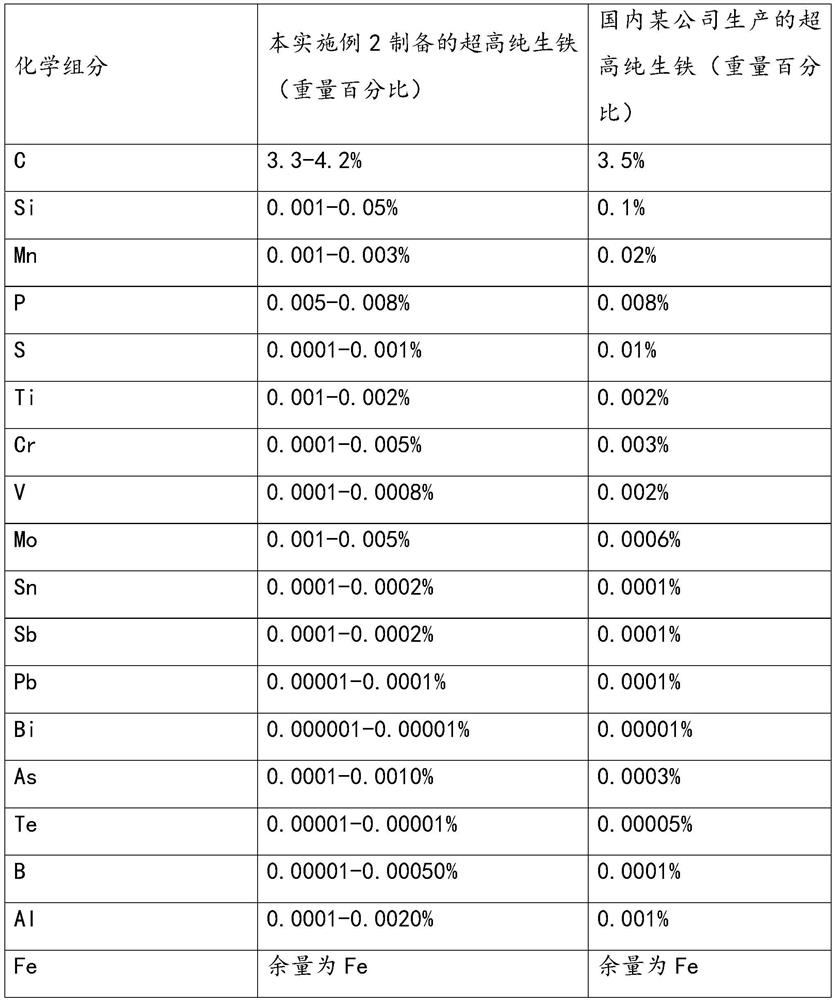

Embodiment 2

[0119] The same technical features of this embodiment and embodiment 1 will not be described in detail. The different technical features of this embodiment and embodiment 1 are that in step (2), the mineral powder is preheated and pre-oxidized to remove the mineral powder. For sulfur and arsenic, preheat and preoxidize the ore powder in the rotary kiln. The conditions for preheating and preoxidation are as follows:

[0120] Control the amount of combustion gas to account for 15%-35% of the gas output of the smelting reduction furnace;

[0121] Control the oxygen content of the oxygen-enriched hot air at 21%-32%;

[0122] Control the discharge temperature of the preheated and preoxidized ore powder at 565-750°C.

[0123] The above conditions satisfy the decomposition of main sulfides in the ore powder and the removal of sulfur combustion, so as to achieve a pre-desulfurization rate of 50-80% and a pre-arsenic removal rate of 30-40%.

[0124] In this embodiment, the desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com