A kind of graphene airgel microsphere with gradient pore structure and its preparation method and application

A technology of graphene airgel and gradient pores, which is applied in the field of nanoporous materials, can solve problems such as the failure to realize the preparation of gradient pore structure graphene airgel microspheres, and achieve rich connotations and applications, large specific surface area, and structural full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

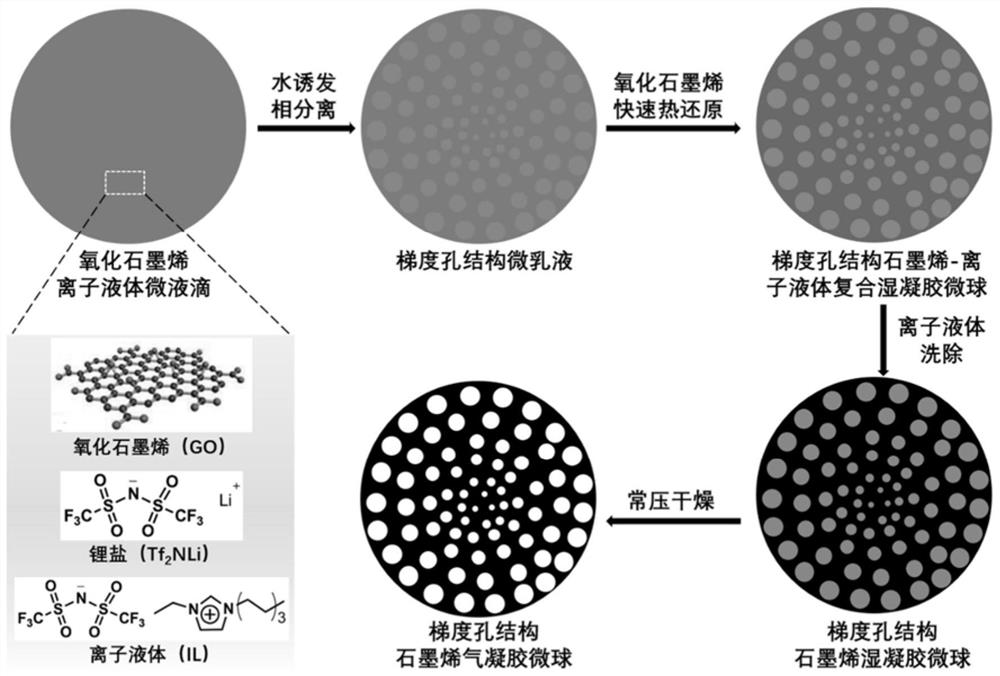

[0032]The present invention provides a kind of preparation method of the graphene airgel microsphere with gradient pore structure in the first aspect, described method comprises the steps:

[0033] (1) Graphene oxide powder, lithium salt and ionic liquid are carried out ultrasonic dispersion, obtain graphene oxide ionic liquid solution; In the present invention, utilize ionic liquid to disperse graphene oxide powder; Ionic liquid is as a kind of green " universal "Solvent" has a good dissolving and dispersing ability to graphene oxide powder; in the present invention, the solubility of the lithium salt in the ionic liquid is large enough to ensure that a sufficiently large osmotic pressure difference is rapidly removed from the surrounding environment. Sufficient moisture is absorbed to induce phase separation in the ionic liquid; other common inorganic salts such as NaCl, etc., have insufficient solubility in the ionic liquid to induce phase separation.

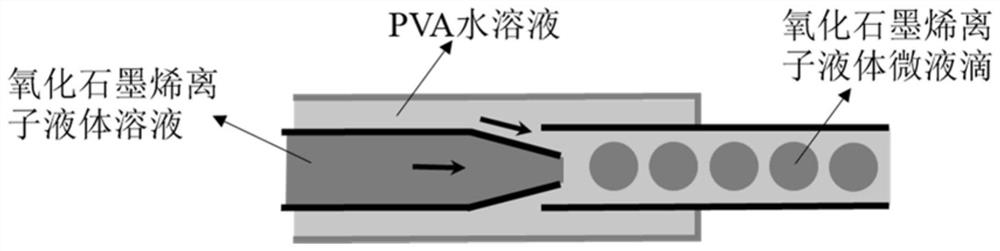

[0034] (2) Use the g...

Embodiment 1

[0088] ①Into a 200mL beaker, add 5g of single-layer graphene oxide powder with a sheet diameter of 50-100nm prepared by the Hummers method, 30g of commercially available lithium salt of bistrifluoromethanesulfonimide, and the synthesized 1-ethyl-3 - 100 g of heptyl imidazole bistrifluoromethanesulfonimide ionic liquid was ultrasonically dispersed for 8 hours by an ultrasonic cleaner with a power of 1000 W to obtain a uniform graphene oxide ionic liquid solution, ready for use.

[0089] ②Use the self-made microfluidic glass chip system to prepare graphene oxide ionic liquid micro-droplets, use a plastic hose and a 5mL disposable syringe to pass the graphene oxide ionic liquid solution as a dispersed phase into the circular glass tube, use plastic The flexible tube and 20mL disposable syringe are passed into the gap between the square glass tube and the circular glass tube with a mass fraction of 10% PVA aqueous solution as the continuous phase, and the Harvard pump is used to ac...

Embodiment 2

[0100] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0101] In step ①, 2 g of single-layer graphene oxide powder with a sheet diameter of 50-100 nm prepared by the Hummers method, 20 g of commercially available lithium salt of bistrifluoromethanesulfonimide, and the synthesized 1- Ethyl-3-heptyl imidazole bistrifluoromethanesulfonimide ionic liquid 100g was ultrasonically dispersed for 8 hours by an ultrasonic cleaner with a power of 1000W to obtain a uniform graphene oxide ionic liquid solution, ready for use.

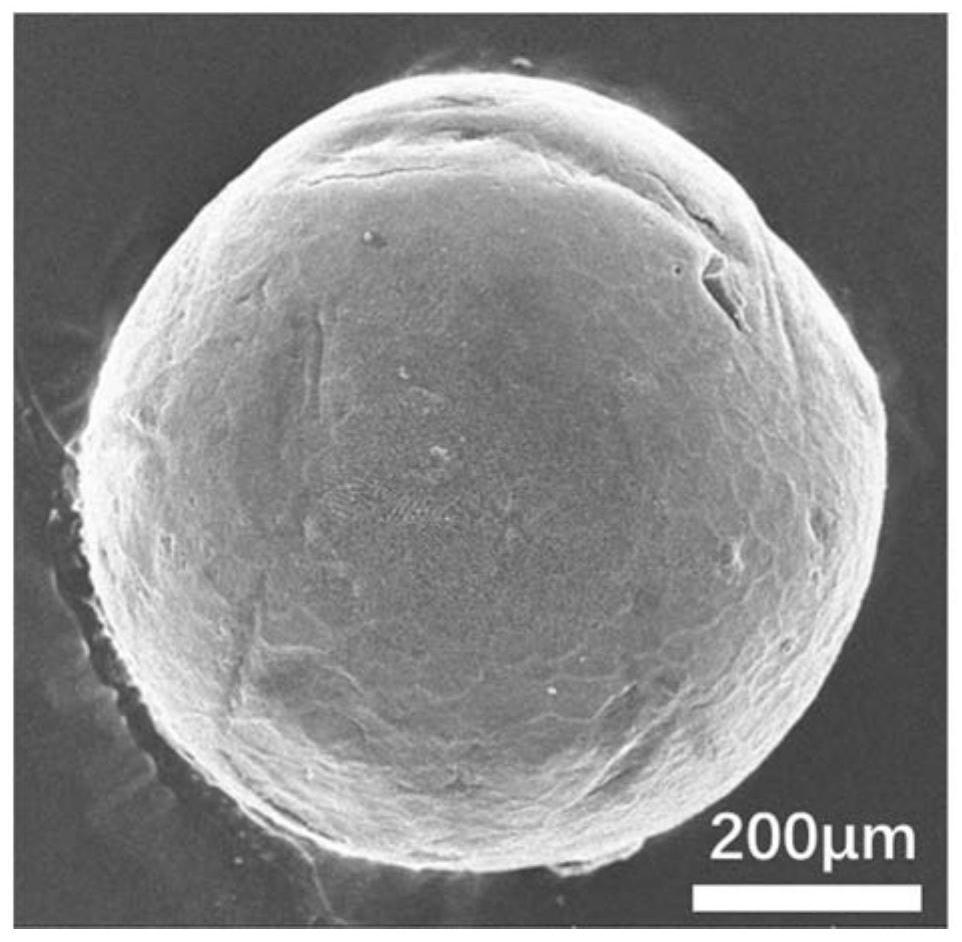

[0102] The graphene airgel microsphere with gradient pore structure obtained in this example has a diameter of 780 μm, has a three-dimensional network pore structure and is distributed in a gradient, and the pore diameter gradually and continuously transitions from the nanopore of 50 nm at the center of the microsphere to the outermost side of the microsphere Micropores of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com