Preparation method of polysiloxane superhydrophobic coating

A super-hydrophobic coating, polysiloxane technology, applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., to achieve the effects of improving preparation efficiency, short lighting time, and large market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] Mix 0.01 g of iodonium salt bis(dodecylphenyl) iodonium hexafluorophosphate (UV-1242) with 1 g of octyltrichlorosilane, stir evenly on a magnetic stirrer, and spread evenly in ethanol In order to obtain a coating on the ultrasonically treated silicon wafer, place the coated silicon wafer in a closed device equipped with an ultraviolet lamp; weigh acetone and water according to the molar ratio of acetone: water = 1:9, and put the two The acetone / water solution is mixed to obtain the acetone / water solution, and the acetone / water solution is formed into a steam effect under the action of a bubbling machine. Under the condition of a bubbling flow rate of 5mL / min, the catheter leads to the coating surface on the silicon wafer in the closed device, and the ultraviolet light is adjusted. Illuminance up to 10mw / cm 2 , cured by light for 60 minutes to obtain the organopolysilane superhydrophobic coating, the water contact angle test results of the organopolysilane superhydrophob...

Embodiment approach 2

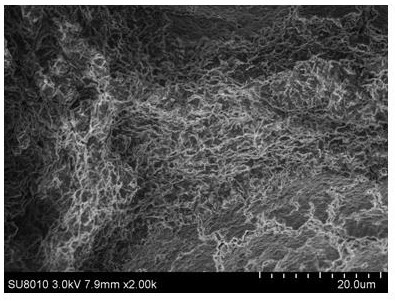

[0021] Mix 0.02 g of iodonium salt bis(dodecylphenyl) iodonium hexafluorophosphate (UV-1242) with 1 g of octadecyltrichlorosilane, stir evenly on a magnetic stirrer, and spread evenly on the Get a coating on a silicon wafer that has been ultrasonically treated in ethanol, place the coated silicon wafer in a closed device equipped with an ultraviolet lamp; weigh acetone and water according to the molar ratio of acetone:water=2:8, and Mix the two to obtain acetone / water solution, and use the acetone / water solution to form a steam effect under the action of a bubbling machine. Under the condition of a bubbling flow rate of 10mL / min, the catheter leads to the coating surface on the silicon wafer in the closed device, and adjusts UV light intensity up to 10mw / cm 2 , cured by light for 50min to obtain the organopolysilane superhydrophobic coating, the water contact angle test results of the organopolysilane superhydrophobic coating are shown in Table 1, and the surface morphology is...

Embodiment approach 3

[0023] Mix 0.02g of bis[4-bis(4-(2-hydroxyethyl)phenyl)sulfonium]-phenylsulfide bishexafluoroantimonate (SP-170) with 1g of hexadecyltrichlorosilane , stir evenly on a magnetic stirrer, and evenly smear the coating on the silicon wafer that has been ultrasonically treated in ethanol in the early stage, and place the coated silicon wafer in a closed device equipped with an ultraviolet lamp; according to the molar ratio Acetone: water = 4:6 Weigh acetone and water, and mix the two to get acetone / water solution, the acetone / water solution forms a steam effect under the action of a bubbling machine, and the bubbling flow rate is 20mL / min, through the catheter Lead to the coating surface on the silicon wafer in the airtight device, adjust the intensity of the ultraviolet light to 50mw / cm 2 , and cured by light for 40 minutes to obtain an organopolysilane superhydrophobic coating. The water contact angle test results of the organopolysilane superhydrophobic coating are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com