Yarrowia lipolytica genetically engineered bacteria and application thereof

A technology of Yarrowia lipolytica and genetically engineered bacteria, which is applied in the field of genetic engineering and can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

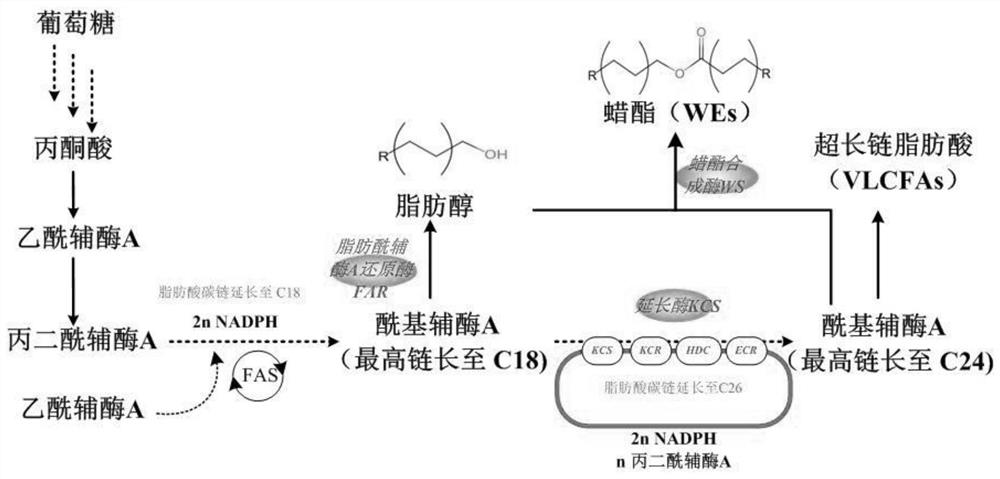

[0092] Example 1 Construction of Yarrowia lipolytica genetically engineered bacteria producing very long-chain fatty acids (VLCFAs)

[0093] (1) Construct the elongase gene AtKCS, CraKCS and MaELO3 expression plasmids p32UTAtKCS, p32UTCraKCS and p32UTMaELO3 with UAS4B+TEF promoters respectively.

[0094] Using primers 32UTAtKCS-f and 32UTAtKCS-r (the nucleotide sequences of which are respectively shown in the sequence table SEQ ID NO: 1-2) to extract the optimized sequence of the elongase gene AtKCS (its nucleus from Arabidopsis thaliana) The nucleotide sequence is shown in SEQ ID NO: 23) was constructed into the plasmid p3204 whose promoter is UAS4B+TEF through restriction sites Pmll and BamHI to obtain plasmid p32UTAtKCS. Using primers 32UTCraKCS-f and 32UTCraKCS-r (the nucleotide sequences thereof are respectively shown in the sequence table SEQ ID NO: 3-4) to extract the optimized sequence (the nucleotide The sequence is shown in SEQ ID NO: 24) was constructed into the pl...

Embodiment 2

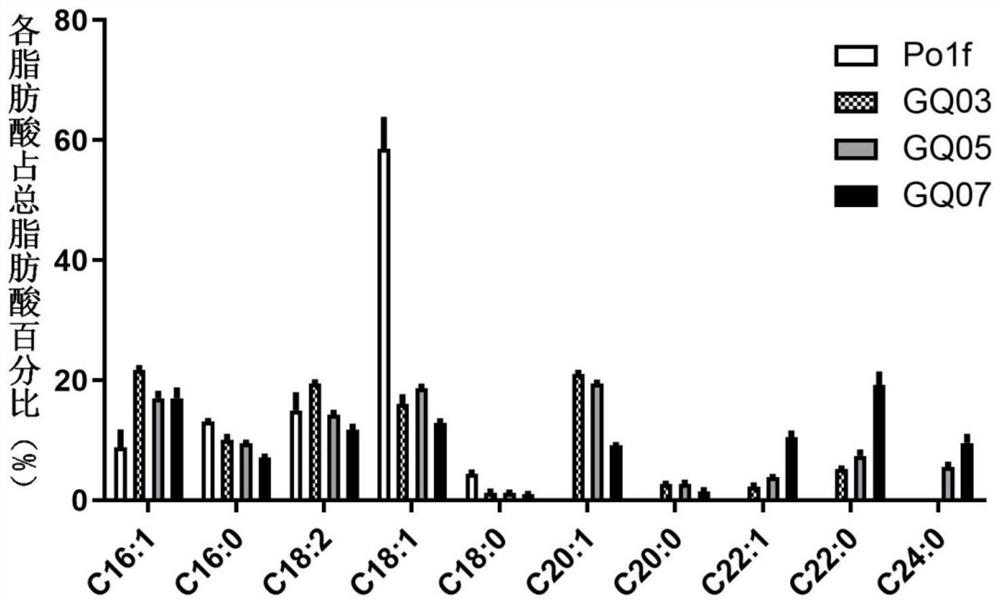

[0104] Embodiment 2 Yarrowia lipolytica genetically engineered bacteria produce the determination of the ratio of each chain length fatty acid

[0105] The bacterial strain Yarrowia lipolytica Po1f, the bacterial strain GQ03 prepared in Example 1, GQ05, GQ07 were respectively inoculated in 2mLYPD medium (this YPD medium is made up of 2% glucose, 2% peptone and 1% yeast extract, and the balance is water, said percentage is mass percent), cultured for 24 hours, then with initial OD 600 The inoculum of 0.01 was inoculated into new 50mL YPD medium for culture. After 3 days of fermentation and cultivation, fatty acids were extracted and then derivatized into fatty acid methyl esters, and the ratio of each fatty acid methyl ester was detected by GC (gas chromatography).

[0106] Extraction of fatty acids: After the fermentation, take 20 mL of the fermentation broth into a centrifuge tube, centrifuge at 4500 rpm for 5 minutes, resuspend with 20 mL of deionized water and wash twice. ...

Embodiment 3

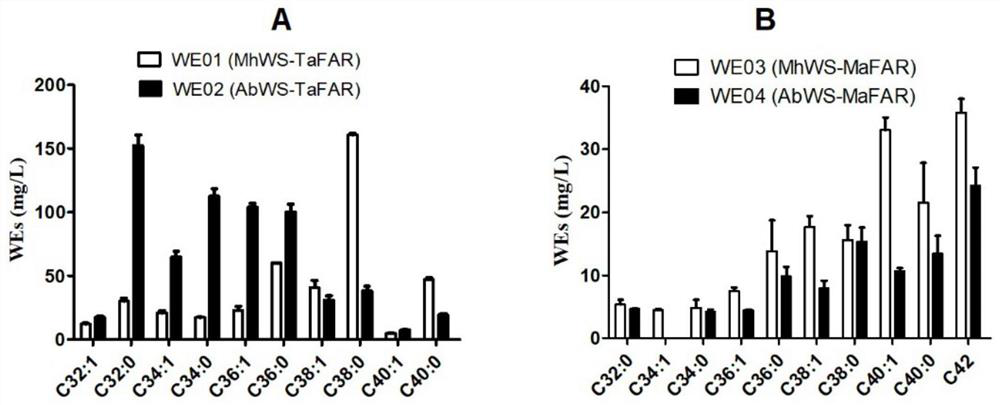

[0113] Example 3 Construction of Yarrowia lipolytica genetically engineered bacteria producing ultra-long-chain wax esters

[0114] (1) The expression plasmids p32UTMaFAR and p32UTTaFAR of fatty acyl-CoA reductase genes MaFAR and TaFAR with UAS4B+TEF promoters were respectively constructed.

[0115] The optimization of the fatty acyl-CoA reductase gene MaFAR derived from Marinobacter aquaeolei VT8 Maqu_2220 was performed using primers 32UTMaFAR-f and 32UTMaFAR-r (the nucleotide sequences of which are shown in the sequence table as SEQ ID NO: 13-14, respectively). The sequence (the nucleotide sequence of which is shown in SEQ ID NO: 26) was constructed into the plasmid p3204 with the promoter UAS4B+TEF through the restriction sites Pmll and BamHI to obtain the plasmid p32UTMaFAR. Use primers 32UTTaFAR-f and 32UTTaFAR-r (the nucleotide sequences of which are respectively shown in the sequence table as SEQ ID NO: 15-16) to extract the fatty acyl-CoA reductase derived from barn ow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com