Method for determining content of biological silicon in sedimentary rock

A technology of sedimentary rock and bio-silicon, which is applied in the field of petroleum geology research, can solve problems such as difficulty in extraction, and achieve the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method and measurement results for determining the biosilicon content of the low-evolution sample NJ-1.

[0042] 1. Sample grinding

[0043] Use a plastic brush to remove the surface attachments of the sedimentary rock NJ-1, clean the agate mortar with water and alcohol, put a small piece of NJ-1 sample, and grind it manually until the particle size is ≤200 mesh.

[0044] 2. Put the ground sample into a sample bottle, dry it at 60°C for 24 hours, take it out and store it in a desiccator.

[0045] 3. Weigh 75 mg of the sample into a 50 mL polyethylene centrifuge tube, add 5 mL of 1 mol / L hydrochloric acid solution into the centrifuge tube, and let it stand for 2 hours until the reaction is complete to remove carbonates. After the reaction was complete, 20 mL of water was added, centrifuged at 3000 rpm for 5 min in a centrifuge, and the supernatant was removed.

[0046] 4. Add 5mL of 10% hydrogen peroxide solution and let stand overnight to re...

Embodiment 2

[0058] This embodiment provides a method and measurement results for determining the biosilicon content of the highly evolved sample YJC-0, and the determination method is the same as that in Example 1.

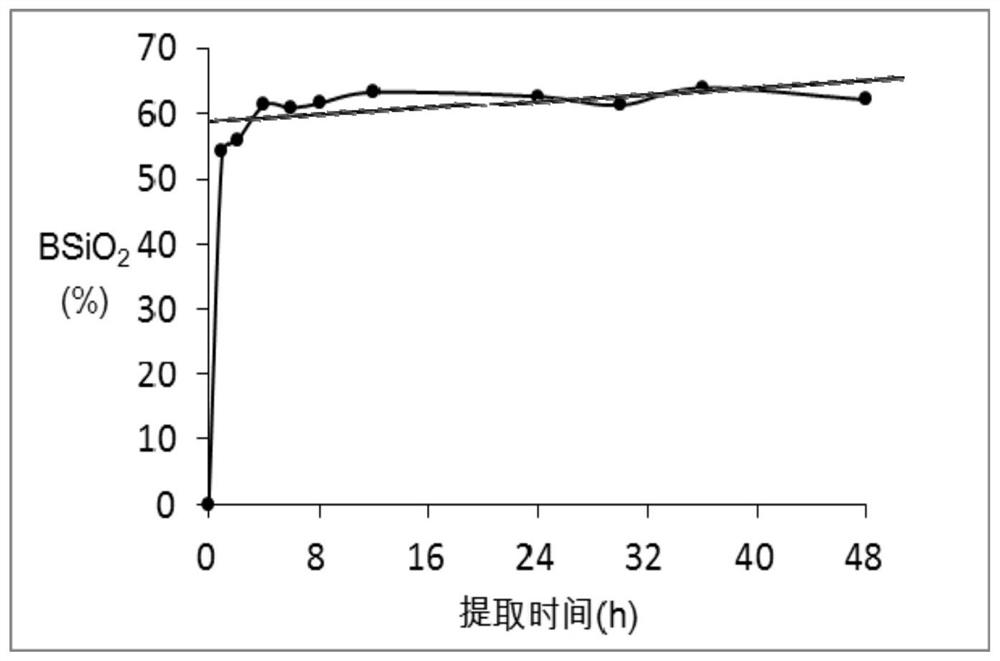

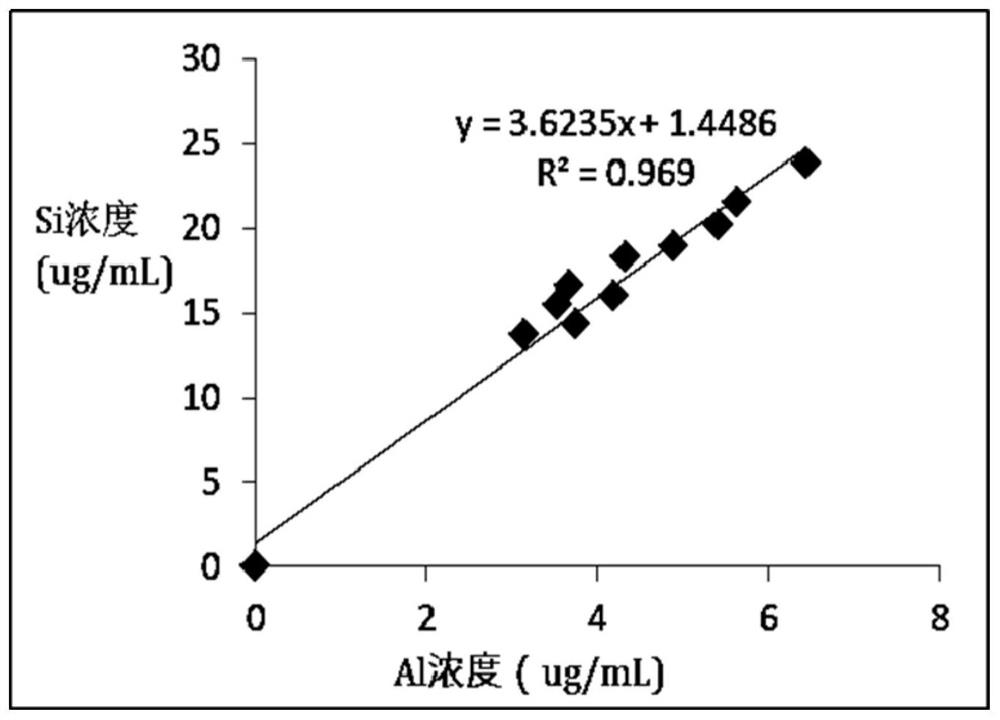

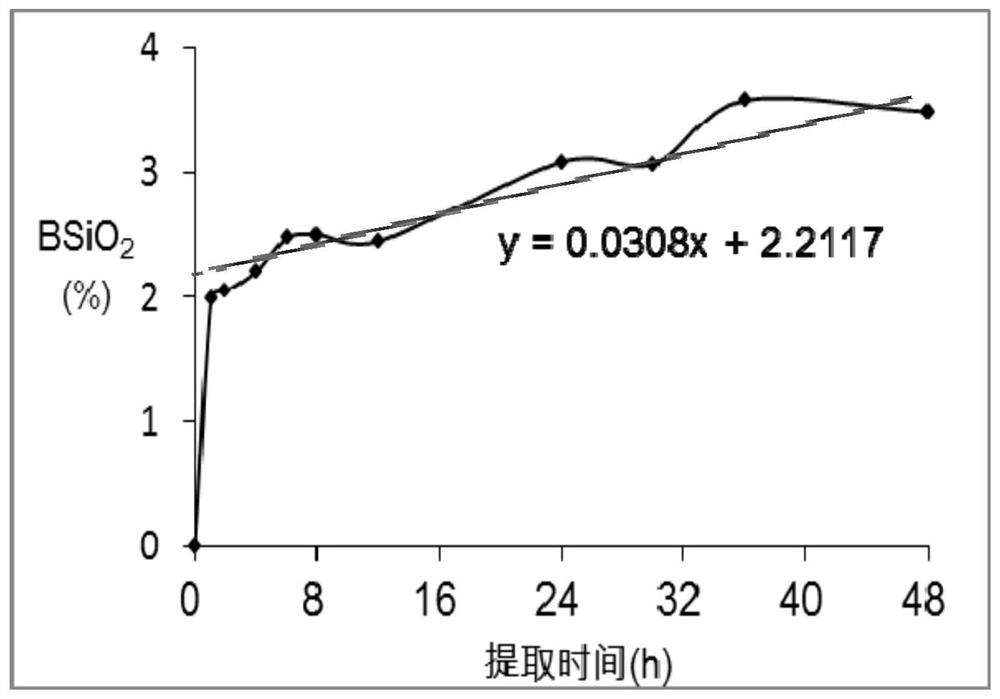

[0059] Table 2 shows the results of the extraction experiment of the highly evolved sample YJC-0. It can be seen from Table 2 that the contents of Si, Al, and Ti in the extraction solution are all low, and the Al content is 10%-25% of the Si content, that is to say Abiotic silicon or higher silicon from clay minerals must be corrected for abiotic silicon. figure 2 It shows the relationship diagram of Si and Al concentration changes in the YJC-0 sample extract solution of Example 2 of the present invention. from figure 2 It is found that the content of Si and Al in the extract varies close to 1:1, so it can be inferred that the ratio of non-biological silicon to Al in the sample is 1:1, and the biological silicon data can be corrected by this coefficient. pass image 3 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com