Precursor material and preparation method thereof, and nitrogen-doped carbon material and application thereof

A nitrogen-doped carbon, precursor technology, used in chemical instruments and methods, nanotechnology for materials and surface science, fuel cell-type half-cells and secondary battery-type half cells, etc., can solve the cumbersome method. , high cost and other problems, to achieve the effect of simple preparation process, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 catalyst

[0046] Example 1

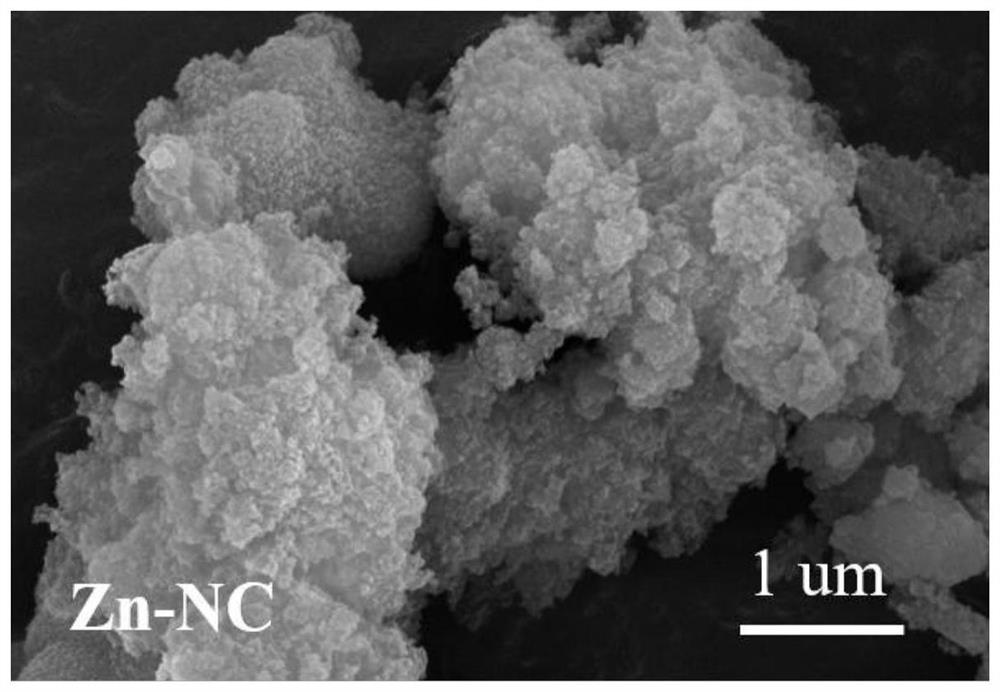

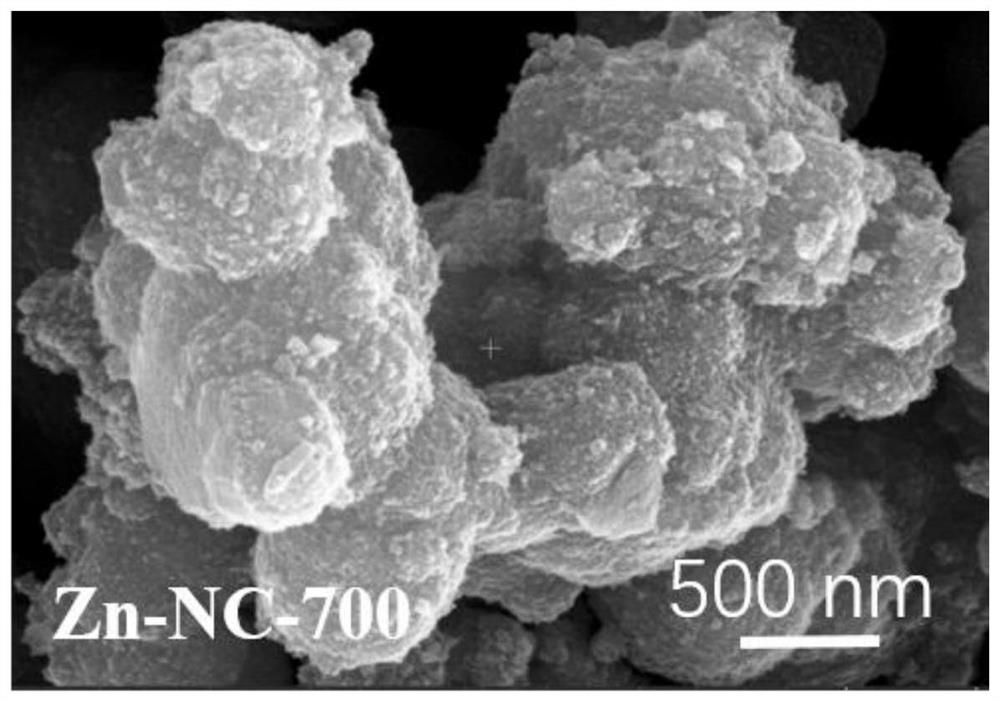

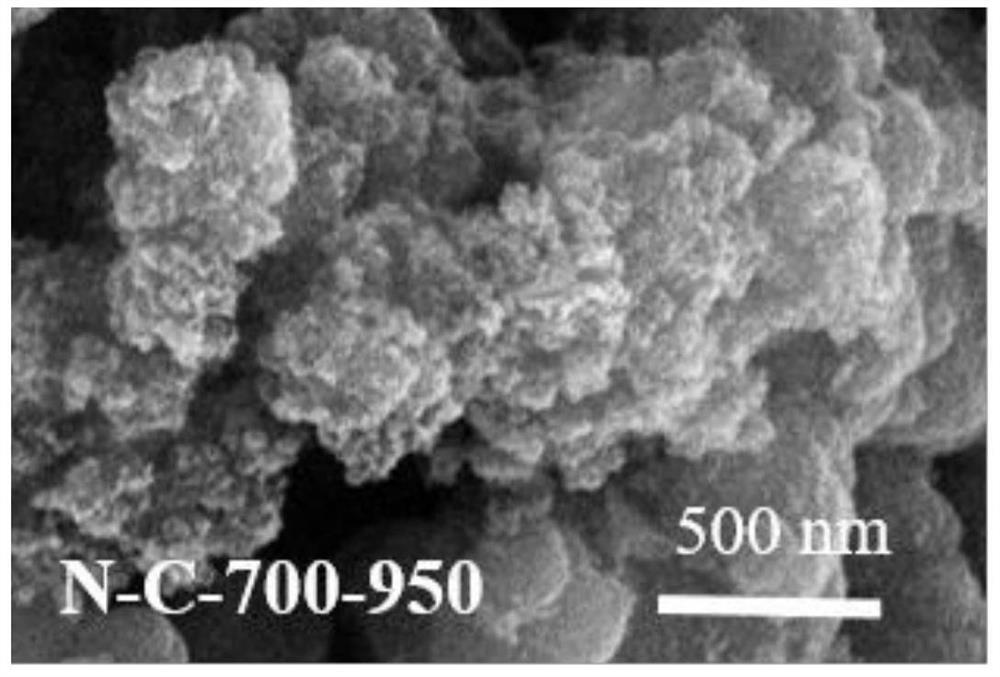

[0047] 0.4951g anhydrous zinc chloride (ZnCl 2 ) into 40mL formamide solution, ultrasonically dissolved, transferred to a hydrothermal reaction kettle, and heated at 180°C for 12h. The mixture in the reactor, at 10000r min -1Centrifuge in a centrifuge for 10 minutes, wash with deionized water 3 times, wash with ethanol 2 times, centrifuge, and place in an oven at 60°C for 12 hours to obtain a reddish-brown substance that is Zn-NC. The obtained above sample was calcined at a temperature of 700°C in a tube furnace for 2h, the heating rate was 5°C / min, and in 1mol L -1 Soak in hydrochloric acid for 24h, at 10000r min -1 Centrifuge in a centrifuge for 10 minutes, wash and dry the above samples to obtain Zn-NC-700, and finally roast Zn-NC-700 at a temperature of 950°C for 2 hours with a heating rate of 5°C / min to obtain defect-rich nitrogen-doped Heterocarbon material is NC-700-950.

[0048] Specific data st...

Embodiment 2

[0050] 40mL of formamide, 0.4951g of ZnCl 2 , 0.2g phenylphosphoric diamide (C 6 h 9 N 2 o 2 P) Add a 50mL reaction kettle, sonicate for a certain period of time until the solution is evenly dispersed, and conduct a hydrothermal reaction at 180°C for 12h. The material after hydroheating is at 10000r min -1 Centrifuge in a centrifuge for 10 min, wash with water three times, wash with alcohol twice, centrifuge and separate, and dry in a vacuum to obtain a black solid powder. Afterwards, the material was put into a tube furnace and calcined at 1000°C for 3 hours in a nitrogen atmosphere with a heating rate of 5°C / min. When the tube furnace was cooled to room temperature, the calcined sample was taken out to obtain the synthesized Zn-PNC-1000. The scanning electron micrograph of the synthesized Zn-PNC-1000 is as follows Figure 4 shown.

Embodiment 3

[0052] Add 1.081g of zinc nitrate into 40mL of formamide solution, ultrasonically dissolve, transfer to a hydrothermal reaction kettle, and heat at 180°C for 12h. The mixture in the reactor, at 10000r min -1 Centrifuge in a centrifuge for 10 minutes, wash with deionized water 3 times, wash with ethanol 2 times, centrifuge, and place in an oven at 60°C for 12 hours to obtain a reddish-brown substance that is Zn-NC. The obtained above sample was calcined at a temperature of 700°C in a tube furnace for 2h, the heating rate was 5°C / min, and in 1mol L -1 Soak in hydrochloric acid for 24h, at 10000r min -1 Centrifuge in a centrifuge for 10 minutes, wash and dry the above samples, and finally roast the samples at a temperature of 950°C for 2 hours with a heating rate of 5°C / min to obtain a defect-rich nitrogen-doped carbon material, which is NC-700-950 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com