Controllable preparation method of CuO nanocrystalline materials with different morphological structures

A nanocrystalline material and nanocrystalline technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of single material morphology and structure, achieve cheap and easy availability of raw materials, and reduce production costs. and efficiency, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

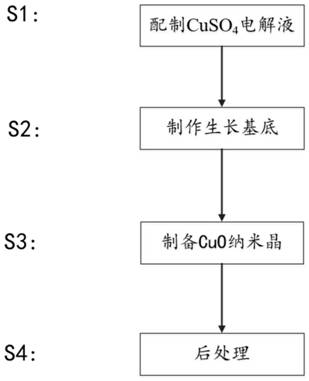

[0029] Such as figure 1 As shown, the controllable preparation method of CuO nanocrystalline materials with different morphological structures provided by the embodiments of the present invention includes the following steps:

[0030] S1, preparation of CuSO 4 electrolyte;

[0031] S2, making a growth substrate;

[0032] S3, preparing CuO nanocrystals;

[0033] S4, post-processing.

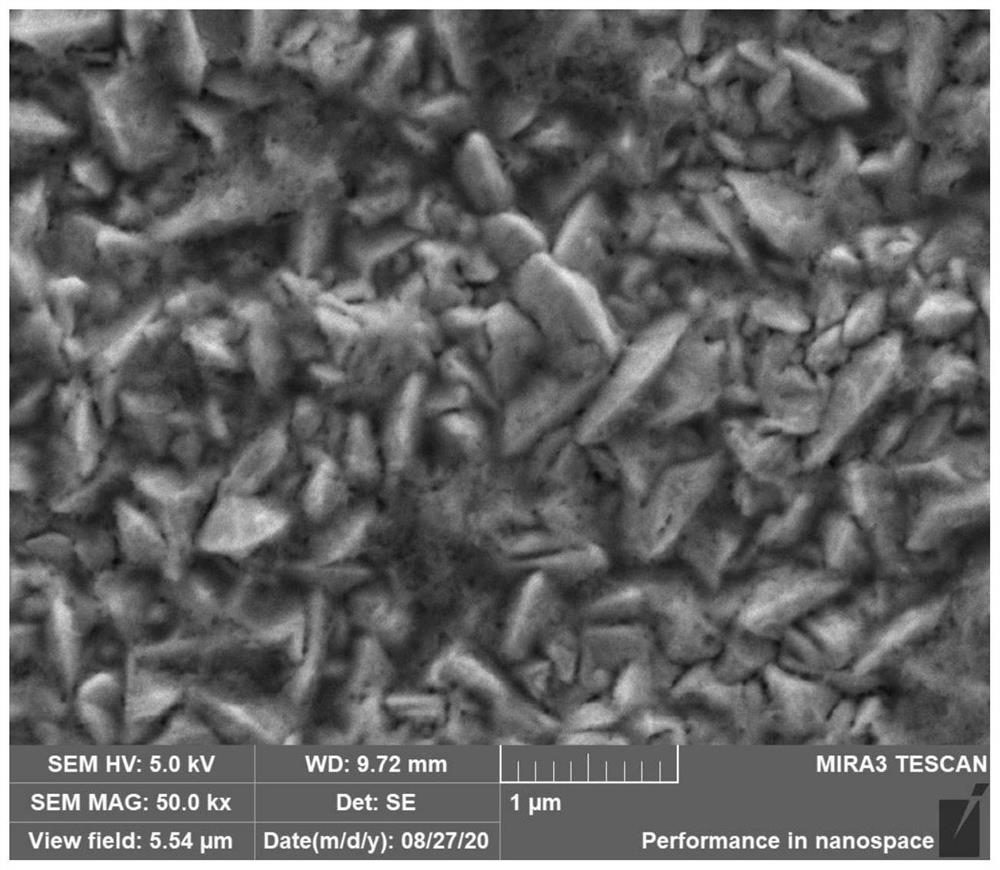

Embodiment 1

[0035] S1, preparation of CuSO 4 electrolyte;

[0036] Specifically: weigh 5g of copper sulfate pentahydrate crystals with an electronic balance and add them to a beaker, then weigh 0.5g of NaCl solids and add them to a beaker, then weigh 0.7g of gelatin solids and add them to a beaker, then use a measuring cylinder to measure 50ml of distilled water, Add distilled water into the beaker along the inner wall of the beaker, and stir with a glass rod while adding to obtain CuSO 4 electrolyte.

[0037] S2: making a growth substrate;

[0038]Specifically: put a copper disc with a diameter of 15mm and a thickness of 1.5mm into a resistance furnace, set the temperature of the resistance furnace to 500°C, and set the time range to 1.5h. Put the copper disc into the ultrasonic cleaner, set the working time of the ultrasonic cleaner to 4min, the cleaning temperature to 30°C, and the power to 100%.

[0039] S3: preparing CuO nanocrystals;

[0040] Specifically: the CuSO obtained in ...

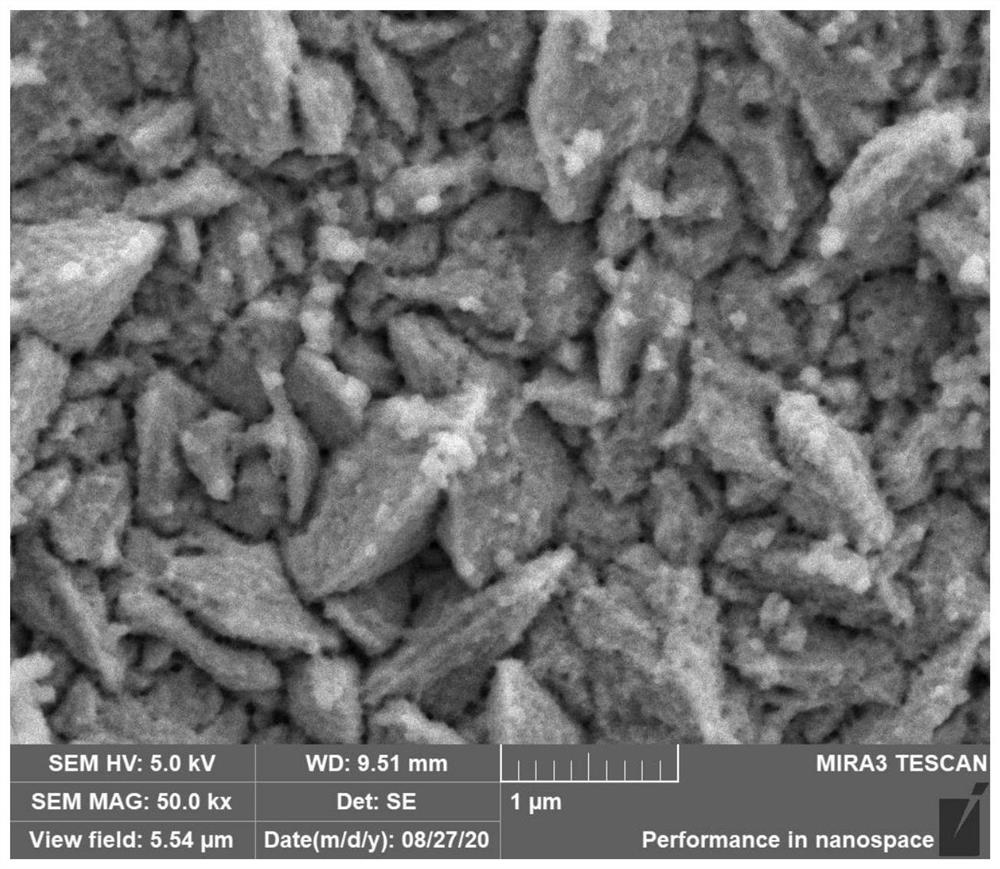

Embodiment 2

[0044] S1, preparation of CuSO 4 electrolyte;

[0045] Specifically: weigh 5g of copper sulfate pentahydrate crystals with an electronic balance and add them to a beaker, then weigh 0.5g of NaCl solids and add them to the beaker, then weigh 0.7g of gelatin solids and add them to the beaker, then measure 50ml of distilled water with a graduated cylinder, Add distilled water into the beaker along the inner wall of the beaker, and stir with a glass rod while adding to obtain CuSO 4 electrolyte.

[0046] S2: making a growth substrate;

[0047] Specifically: put a copper disc with a diameter of 15mm and a thickness of 1.5mm into a resistance furnace, set the temperature of the resistance furnace to 500°C, and set the time range to 1.5h. Put the copper disc into the ultrasonic cleaner, set the working time of the ultrasonic cleaner to 4min, the cleaning temperature to 30°C, and the power to 100%.

[0048] S3: preparing CuO nanocrystals;

[0049] Specifically: the CuSO obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com