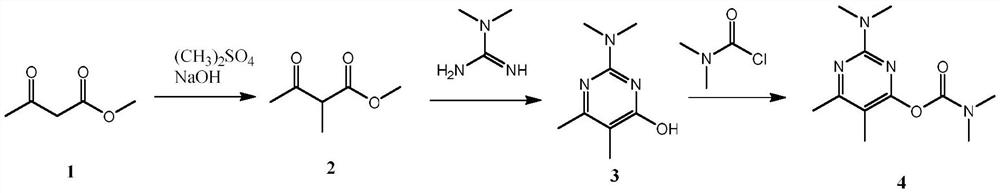

Synthesis method of pirimicarb intermediate 2-methyl acetoacetate

A technology of methyl methyl acetoacetate and a synthetic method, which is applied in the field of synthesis of pirimicarb intermediate 2-methyl acetoacetate, can solve problems such as low yield and side reactions, and achieve high product yield , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

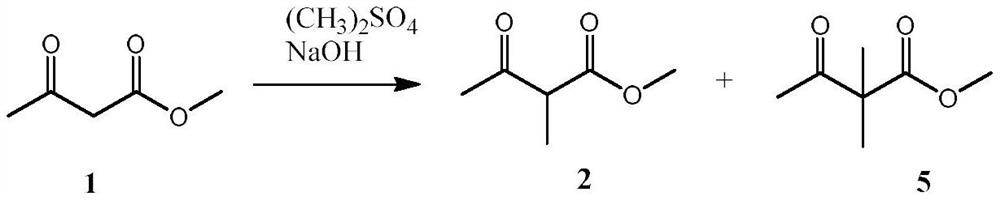

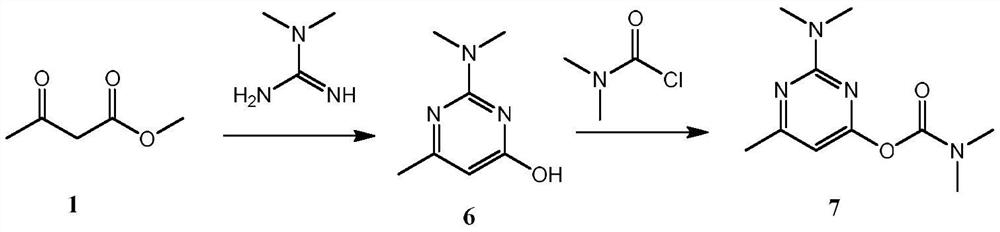

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Synthesis of methyl 2-acetyl acrylate:

[0042] Under nitrogen protection, add 10.0g methyl acrylate (98%, 114mmol), 10.0g acetyl chloride (98%, 125mmol), 40ml ether and 0.05g 4-methoxyl-phenol in a three-necked flask, add dropwise 12.92g under a water bath Triethylamine (98%, 125mmol), keep the reaction temperature at 20-25°C, keep it warm for 4 hours after the dropwise addition, add 40ml of water solution, wash the organic phase with 30ml of water three times, dry over anhydrous magnesium sulfate, and concentrate under vacuum to obtain 16.5g pale yellow liquid.

[0043] GC-MS(EI): 128.1, 1 H NMR: (400MHz, CDCl 3 ):ppmδH 5.80(s,1H), 5.77(s,1H), 3.75(s,3H) 2.30(s,3H).

[0044] (2) Synthesis of 2-methyl acetoacetate:

[0045] Dissolve 16.5g of the above product in 60ml of ethanol in a hydrogenation kettle, add 1.0g of 5% palladium-carbon catalyst (5g of metal palladium loaded on 95g of activated carbon), replace the air and feed hydrogen to 0.05MPa, and react at ...

Embodiment 2

[0048] (1) Synthesis of methyl 2-acetyl acrylate:

[0049] Under nitrogen protection, add 10.0g methyl acrylate (98%, 114mmol), 10.0g acetyl chloride (98%, 125mmol), 40ml methyl tert-butyl ether and 0.05g 2-tert-butyl-4-methane Base phenol, add 16.5g DIPEA (98%, 125mmol) dropwise in a water bath, keep the reaction temperature at 20-25°C, keep warm for 4 hours after the dropwise addition, add 40ml of water, wash the organic phase three times with 30ml of water, and dry over anhydrous magnesium sulfate , concentrated under reduced pressure in vacuo to obtain 16.8 g of light yellow liquid.

[0050] (2) Synthesis of 2-methyl acetoacetate:

[0051] Dissolve 16.8g of the above product in 60ml of ethanol in a hydrogenation kettle, add 1.0g of 5% palladium-carbon catalyst (5g of metal palladium supported on 95g of activated carbon), replace the air and feed hydrogen to 0.05MPa, and react at room temperature for 5 Hours, after the reaction was completed, the catalyst was removed by fil...

Embodiment 3

[0053] (1) Synthesis of methyl 2-acetyl acrylate:

[0054] Under nitrogen protection, add 10.0g methyl acrylate (98%, 114mmol), 10.0g acetyl chloride (98%, 125mmol), 30ml 2-methyltetrahydrofuran and 0.05g 2,6-di-tert-butyl-4 -Methyl phenol, add DABCO's 2-methyltetrahydrofuran solution (14.3g DABCO (98%, 125mmol), 20ml 2-methyltetrahydrofuran) dropwise under a water bath, keep the reaction temperature at 20-25°C, and keep the temperature for 4 40ml water solution was added, the organic phase was washed three times with 30ml water, dried over anhydrous magnesium sulfate, and concentrated under reduced pressure in vacuo to obtain 16.7g light yellow liquid.

[0055] (2) Synthesis of 2-methyl acetoacetate:

[0056] Dissolve 16.7g of the above product in 60ml of ethanol in a hydrogenation kettle, add 1.0g of 5% palladium-carbon catalyst (5g of metal palladium supported on 95g of gac), replace the air and feed hydrogen to 0.05MPa, and react at room temperature for 5 Hours, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com