Biological enhancement application method of sulfate reducing bacteria

A bio-augmentation and sulfate technology, applied in the field of environmental microorganisms, can solve problems such as pollution, irritating odor, and difficulty in the growth of sulfate-reducing bacteria, and achieve the effect of reducing environmental pollution and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for applying sulfate-reducing bacteria bioaugmentation, the steps are as follows:

[0037] (1) Prepare bio-augmented medium: add 1.5g KH to 1L distilled water 2 PO 4 , 2.5 g / L NaCl, 2.0g / L sodium lactate, 0.5g / L peptone, 1.5g / L Na 2 SO 4 , 0.05 g / L MgCl 2 ·6H 2 O, 0.05g / L CaCl 2 . Add 1mol / L NaOH to adjust the pH to 7.0. The prepared culture was sterilized at 121°C for 20 minutes, and cooled for later use.

[0038] (2) Take 0.5g glucose, 1.0g NH 4 Cl, 0.1g ascorbic acid, 1.0g urea sterilized by UV alone for 30min, 20mgCdCl 2 Add to the above-prepared 1L solution.

[0039] (3) Take the culture solution of sulfate-reducing bacteria and urease-producing strains at a volume ratio of 1:1, and add the two microorganisms into the bio-augmented culture solution at the same time. .

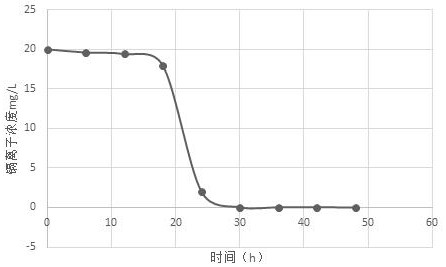

[0040] (4) The mixed bacterial solution was cultured in a constant temperature oscillator at 30-35°C and 60-85 r / min for 24 hours, and the Cd in the medium was determined by fla...

Embodiment 2

[0042] (1) Prepare bio-augmented medium: add 1.5g KH to 1L distilled water 2 PO 4 , 2.5 g / L NaCl, 2.0g / L sodium lactate, 0.5g / L peptone, 1.5g / L Na 2 SO 4 , 0.05 g / L MgCl 2 ·6H 2 O, 0.05g / L CaCl 2 . Add 1mol / L NaOH to adjust the pH to 7.0. The prepared culture was sterilized at 121°C for 20 minutes, and cooled for later use.

[0043] (2) Take 0.5g glucose, 1.0g NH 4 Cl, 0.1g ascorbic acid, 1.0g urea sterilized by UV alone for 30min, 20mgCdCl 2 Add to the above-prepared 1L solution.

[0044] (3) Take the culture solution of sulfate-reducing bacteria and urease-producing strains at a volume ratio of 1:1, first add the urease-producing strains for 3 hours, and then add sulfate-reducing bacteria. Closed culture.

[0045] (4) The mixed bacterial solution was cultured in a constant temperature oscillator at 30-35°C and 60-85 r / min for 24 hours, and the Cd in the medium was determined by flame atomic absorption spectrophotometry. 2+ content.

Embodiment 3

[0047] (1) Prepare bio-augmented medium: add 1.5g KH to 1L distilled water 2 PO 4 , 2.5 g / L NaCl, 2.0g / L sodium lactate, 0.5g / L peptone, 1.5g / L Na 2 SO 4 , 0.05 g / L MgCl 2 ·6H 2 O, 0.05g / L CaCl 2 . Add 1mol / L NaOH to adjust the pH to 7.0. The prepared culture was sterilized at 121°C for 20 minutes, and cooled for later use.

[0048] (2) Take 0.5g glucose, 1.0g NH 4 Cl, 0.1g ascorbic acid, 1.0g urea sterilized by UV alone for 30min, 20mgCdCl 2 Add to the above-prepared 1L solution.

[0049] (3) Take the culture solution of sulfate-reducing bacteria and urease-producing strains at a volume ratio of 1:1, first add sulfate-reducing bacteria for 3 hours, and then add urease-producing strains. Closed culture.

[0050] (4) The mixed bacterial solution was cultured in a constant temperature oscillator at 30-35°C and 60-85 r / min for 24 hours, and the Cd in the medium was determined by flame atomic absorption spectrophotometry. 2+ content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com