Preparation method of PET-based heat reflecting film

A heat-reflecting film and thermal compounding technology, which is applied in chemical instruments and methods, flat products, lamination, etc., can solve problems such as temperature rise, low yield of adhesives, and low peel strength, so as to increase high-temperature viscosity and timeliness , Excellent weather resistance and heat resistance, strong ability to shield ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

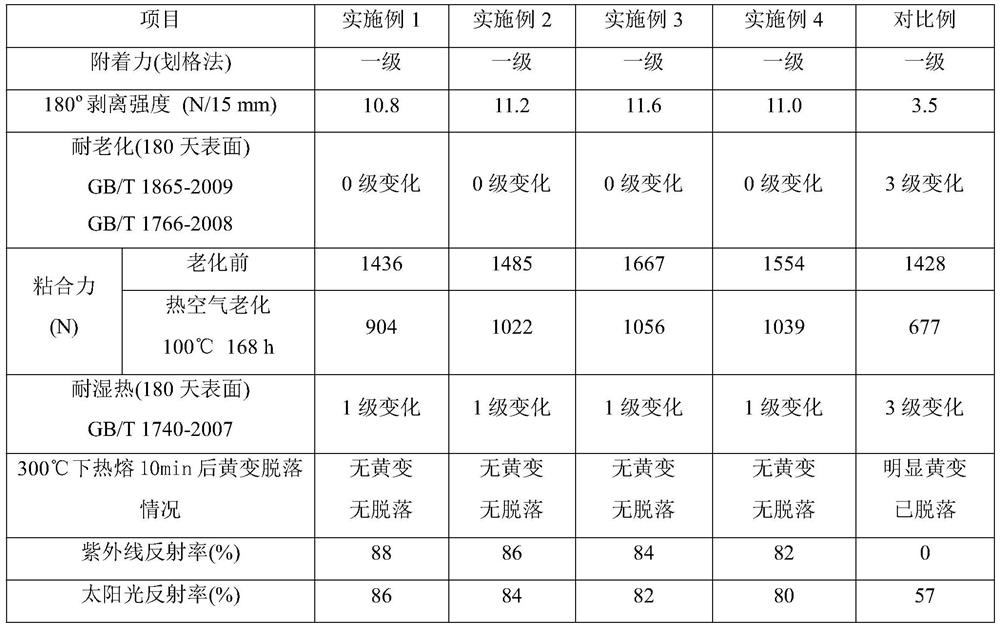

Examples

Embodiment 1

[0018] A preparation method of a PET-based heat reflective film, comprising the following steps:

[0019] (1) Through the particle size of 2nm nano-SiO 2 Particle-modified PET to obtain modified PET;

[0020] (2) After the modified PET raw material is pre-crystallized and dried, it enters the extruder for melting and plasticization, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; it is pressed on the quenching wheel by the electrostatic adsorption device. , rapidly cooled to form a cast piece, and then stretched longitudinally and transversely (the longitudinal stretching ratio is 3.0, and the transverse stretching ratio is 3.4). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET thermal composite film;

[0021] (3) after the 0.06mm aluminum plate is cleaned, passivated and dried, the obtained PET thermal composite film is compounded w...

Embodiment 2

[0024] A preparation method of a PET-based heat reflective film, comprising the following steps:

[0025] (1) Through the particle size of 6nm nano-SiO 2 Particle-modified PET to obtain modified PET;

[0026] (2) After the modified PET raw material is pre-crystallized and dried, it enters the extruder for melting and plasticization, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; it is pressed on the quenching wheel by the electrostatic adsorption device. , rapidly cooled to form a cast piece, and then stretched longitudinally and transversely (the longitudinal stretching ratio is 3.2, and the transverse stretching ratio is 3.6). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET thermal composite film;

[0027] (3) after the 0.06mm aluminum plate is cleaned, passivated and dried, the obtained PET thermal composite film is compounded w...

Embodiment 3

[0030] A preparation method of a PET-based heat reflective film, comprising the following steps:

[0031] (1) Through the particle size of 12nm nano-SiO 2 Particle-modified PET to obtain modified PET;

[0032] (2) After the modified PET raw material is pre-crystallized and dried, it enters the extruder for melting and plasticization, and then passes through the pre-filter, metering pump, and main filter to carry out the die head; it is pressed on the quenching wheel by the electrostatic adsorption device. , rapidly cooled to form a cast sheet, and then stretched longitudinally and transversely (the longitudinal stretching ratio is 3.4, and the transverse stretching ratio is 3.8). The base film undergoes shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online winding to obtain a PET thermal composite film;

[0033] (3) after the 0.06mm aluminum plate is cleaned, passivated and dried, the obtained PET thermal composite film is compounded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com