Method and device for preparing vinyl chloride by treating bis(trichloromethyl) carbonate production tail gas through catalytic chlorination process

A technology of trichloromethyl and carbonate is applied in the field of preparing vinyl chloride and treating dicarbonate production tail gas by catalytic chlorination, which can solve the problems of low concentration of available chlorine in solution, high storage and transportation pressure, environmental pollution, etc. Achieve high-value reuse, low power consumption, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

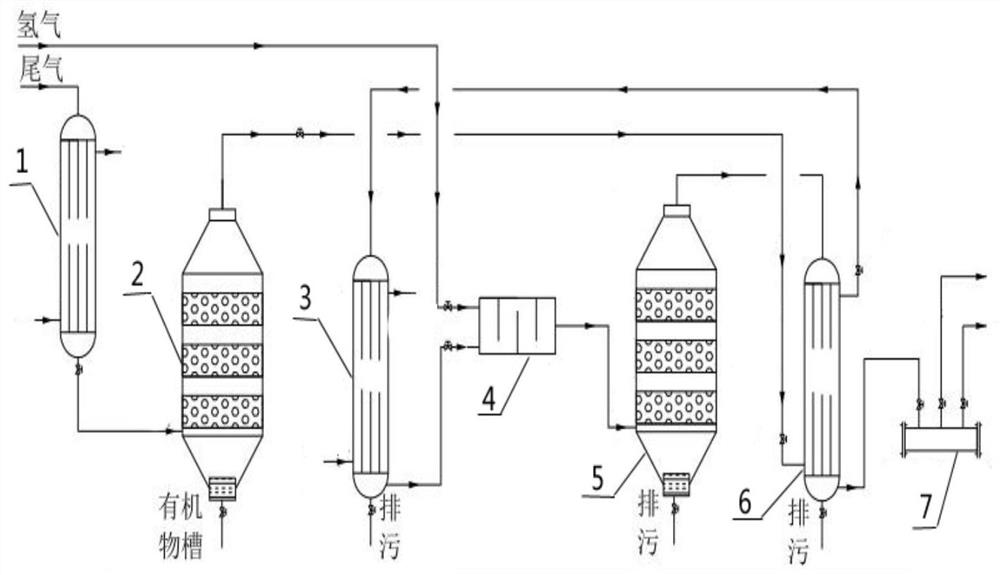

[0028] A kind of catalytic chlorination process bis (trichloromethyl) carbonate production tail gas is used for the method for preparing vinyl chloride, it is characterized in that, comprises the following steps:

[0029] (1) The tail gas produced by the production of bis(trichloromethyl)carbonate is called chlorinated tail gas, and its main components are: 97.2% by volume of hydrogen chloride, 0.6% by volume of chlorine gas, The percentage content is 0.4%, the chloride of dimethyl carbonate (the chloride of dimethyl carbonate is C 3 h 6-n o 3 CL n , wherein n is an integer from 1 to 6) the volume percentage is 0.95%. The chlorinated tail gas is passed into cryocooler 1 for cooling. The cryocooler 1 uses circulating cold water for cooling. The cold water enters the upper return water from the lower part of the cryocooler for recycling. The internal temperature of the cryocooler is -32°C. The contained organic gas is condensed into organic liquid droplets in the cryocooler,...

Embodiment 2

[0036] A kind of catalytic chlorination process bis (trichloromethyl) carbonate production tail gas is used for the method for preparing vinyl chloride, comprises the following steps:

[0037] (1) The tail gas produced by the production of bis(trichloromethyl)carbonate is called chlorinated tail gas, and its main components are: 97.5% by volume of hydrogen chloride, 0.8% by volume of chlorine gas, and The percentage content is 0.5%, the chloride of dimethyl carbonate (the chloride of dimethyl carbonate is C 3 h 6-n o 3 CL n , wherein n is an integer from 1 to 6) the volume percentage is 0.9%. The chlorinated tail gas is passed into cryocooler 1 for cooling. The cryocooler 1 is cooled by circulating cold water. The cold water enters the upper return water from the lower part of the cryocooler for recycling. The internal temperature of the cryocooler is -35°C. The contained organic gas is condensed into organic liquid droplets in the cryocooler, and the temperature of the or...

Embodiment 3

[0044] A kind of catalytic chlorination process bis (trichloromethyl) carbonate production tail gas is used for the method for preparing vinyl chloride, it is characterized in that, comprises the following steps:

[0045] (1) The tail gas produced by the production of bis(trichloromethyl)carbonate is called chlorinated tail gas, and its main components are: 97.6% by volume of hydrogen chloride, 0.7% by volume of chlorine gas, and The percentage content is 0.6%, the chloride of dimethyl carbonate (the chloride of dimethyl carbonate is C 3 h 6-n o 3 CL n , wherein n is an integer from 1 to 6) the volume percentage is 1.1%. The chlorinated tail gas is passed into the cryocooler 1 for cooling. The cryocooler 1 is cooled by circulating cold water. The cold water enters the upper return water from the lower part of the cryocooler and is recycled. The internal temperature of the cryocooler is -40 °C, and the exhaust gas The contained organic gas is condensed into organic liquid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com