Graphene/polymer multi-orientation filling modified chemical fiber and preparation method thereof

A graphene and polymer technology, applied in the field of fiber modification, can solve the problems of difficulty in obtaining fiber materials, inability to take into account fiber strength and toughness, and difficulty in achieving extensive control, etc., and achieve the effect of strong controllability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

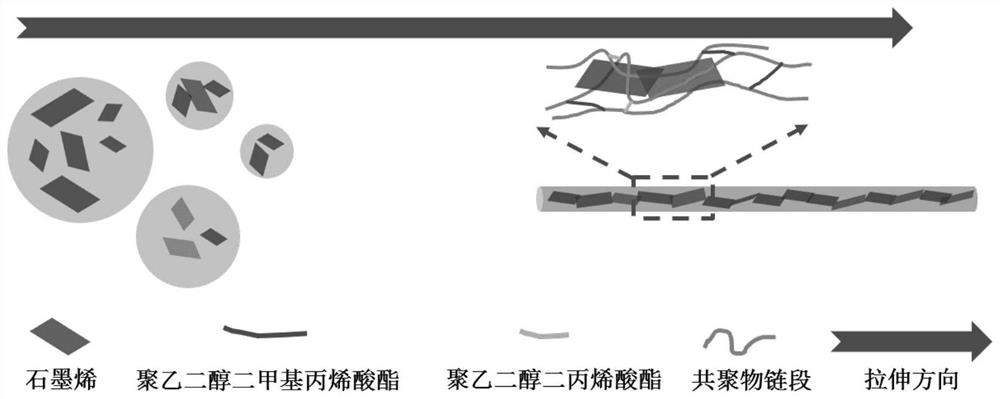

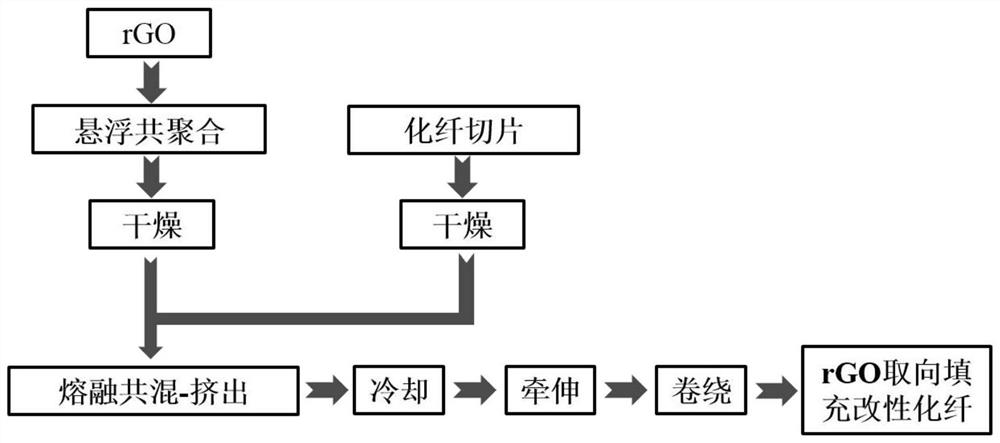

[0033] The invention provides a kind of preparation method of graphene / polymer multi-orientation filled modified chemical fiber, comprising the following steps:

[0034]Mixing graphene, propylene monomer, acrylate monomer, comonomer, macromolecular crosslinking agent and initiator to obtain a mixed solution;

[0035] Mixing the mixed liquid and the aqueous phase dispersion system, performing homogenization treatment, to obtain a suspension;

[0036] The suspension is subjected to in-situ suspension polymerization to obtain graphene / polymer microspheres;

[0037] The graphene / polymer microsphere and the chemical fiber matrix are placed in a twin-screw extruder for melt blending, and after drawing, the graphene / polymer multi-oriented filled modified chemical fiber is obtained.

[0038] In the present invention, unless otherwise specified, the preparation materials used are commercially available products well known to those skilled in the art.

[0039] The invention mixes grap...

Embodiment 1

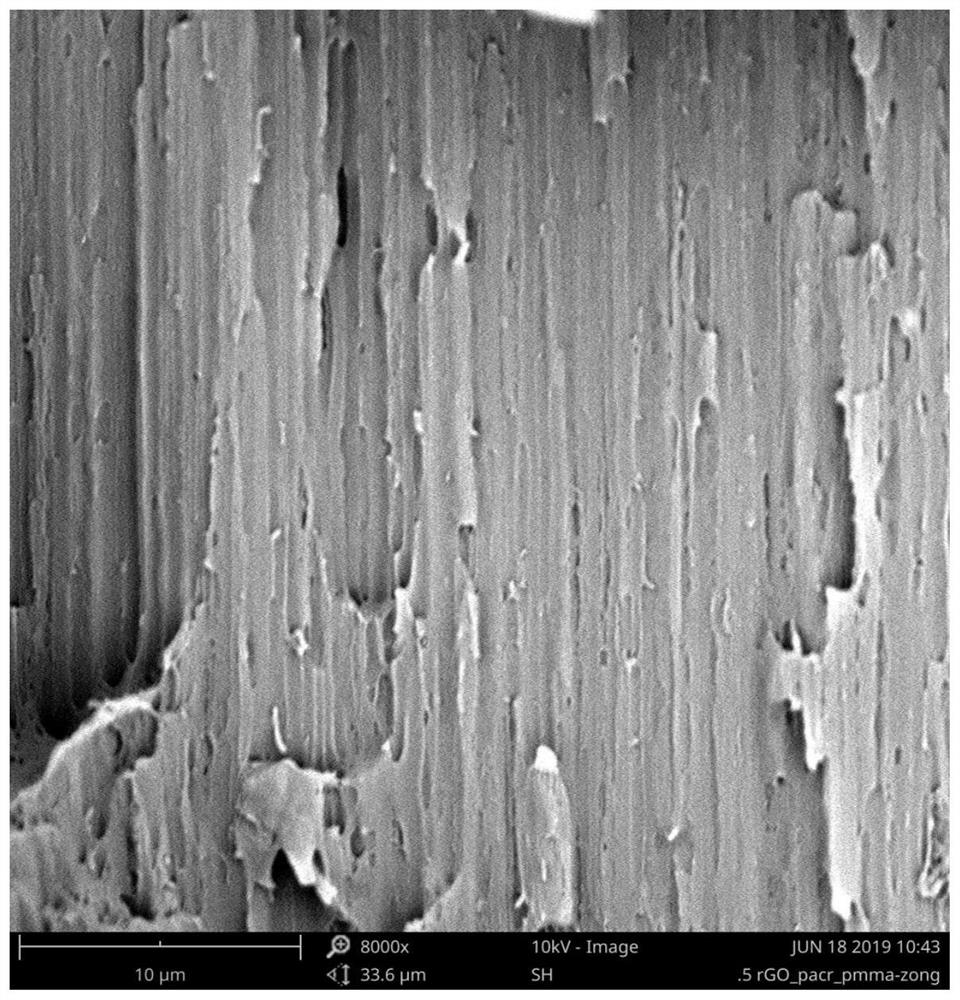

[0064] according to figure 2 The preparation flowchart shown in the preparation of graphene orientation filled modified chemical fiber, 0.1g graphene, 10g methyl methacrylate (MMA), 40g butyl acrylate (BA), 50g styrene (St), 0.2g polyethylene Glycol dimethacrylate (PEGDMA-750), 0.2g polyethylene glycol diacrylate (PEGDA-200), 2g benzoyl peroxide (BPO) and 1g azobisisobutyronitrile (AIBN) were mixed, Disperse for 2h under 100W ultrasonic conditions to obtain a mixed solution; mix the mixed solution with an aqueous phase dispersion system (6.85g magnesium hydroxide, 0.25gNaNO 2 and 50gNaCl uniformly dispersed in 500g deionized water), and high-speed shearing (stirring speed is 10000rpm, time is 5min) to obtain a suspension; the suspension is polymerized in high-purity nitrogen, first at 2°C / min The heating rate was raised to 50°C, and the reaction was carried out for 6 hours, and then the temperature was raised to 70°C at a heating rate of 5°C / min, and the reaction was carried...

Embodiment 2

[0067] It is basically the same as Example 1, except that the masses of MMA, BA and St are respectively 40g, 20g and 40g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com